Wire guiding member

A component and wire technology, applied in the field of wire components, can solve the problems of inability to press the wire, the pressure roller cannot follow completely, the axial movement of the spool, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

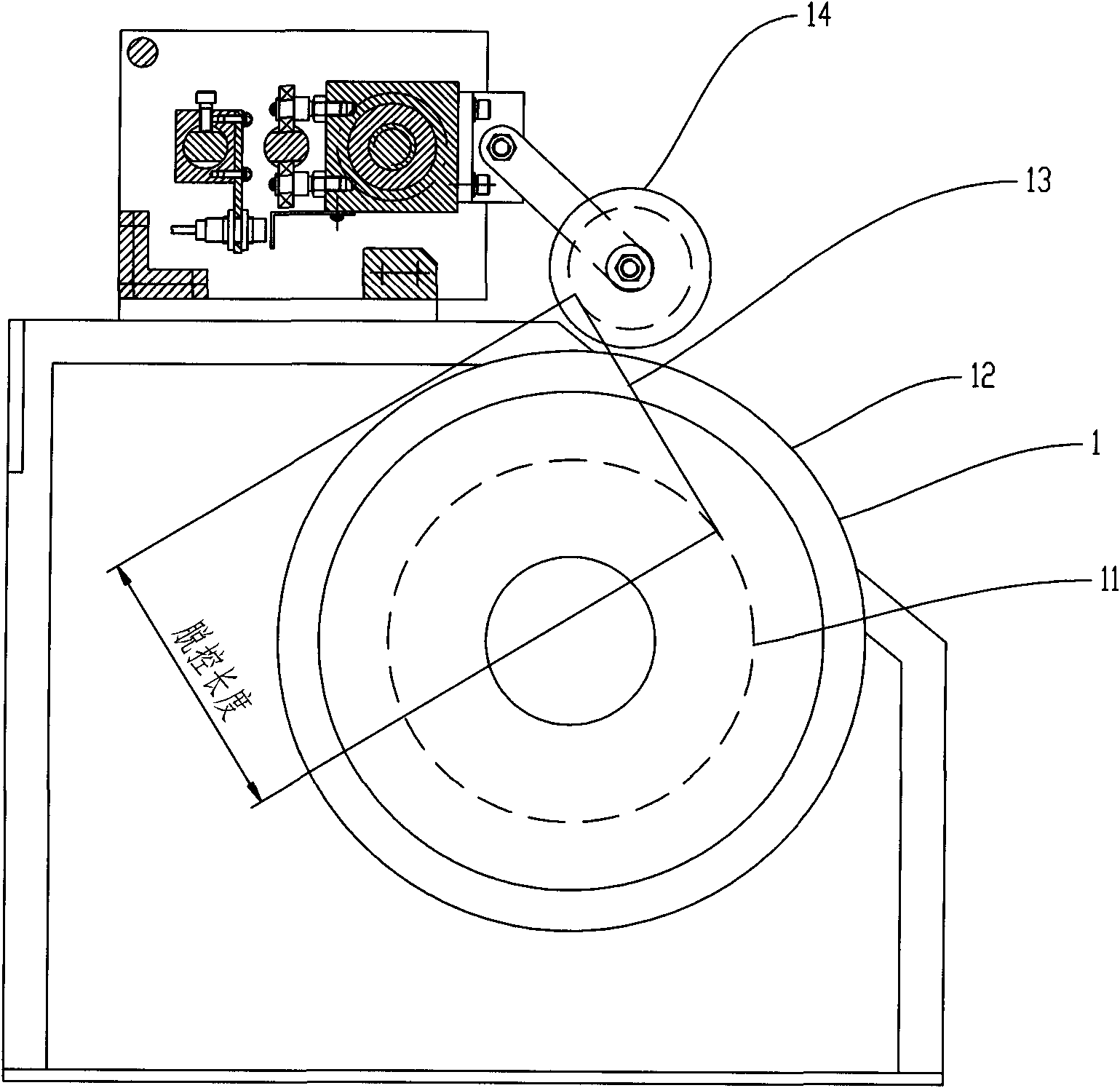

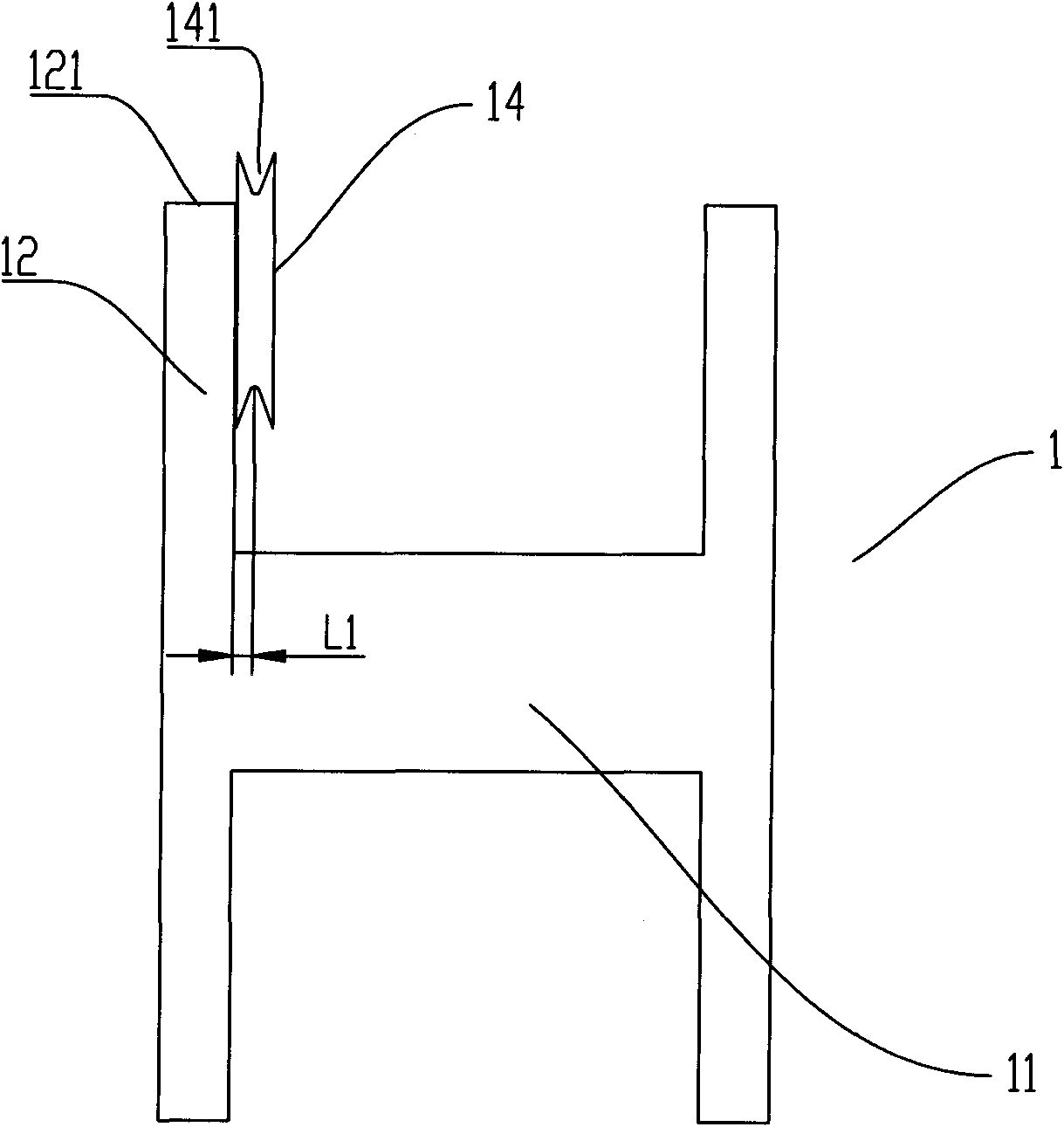

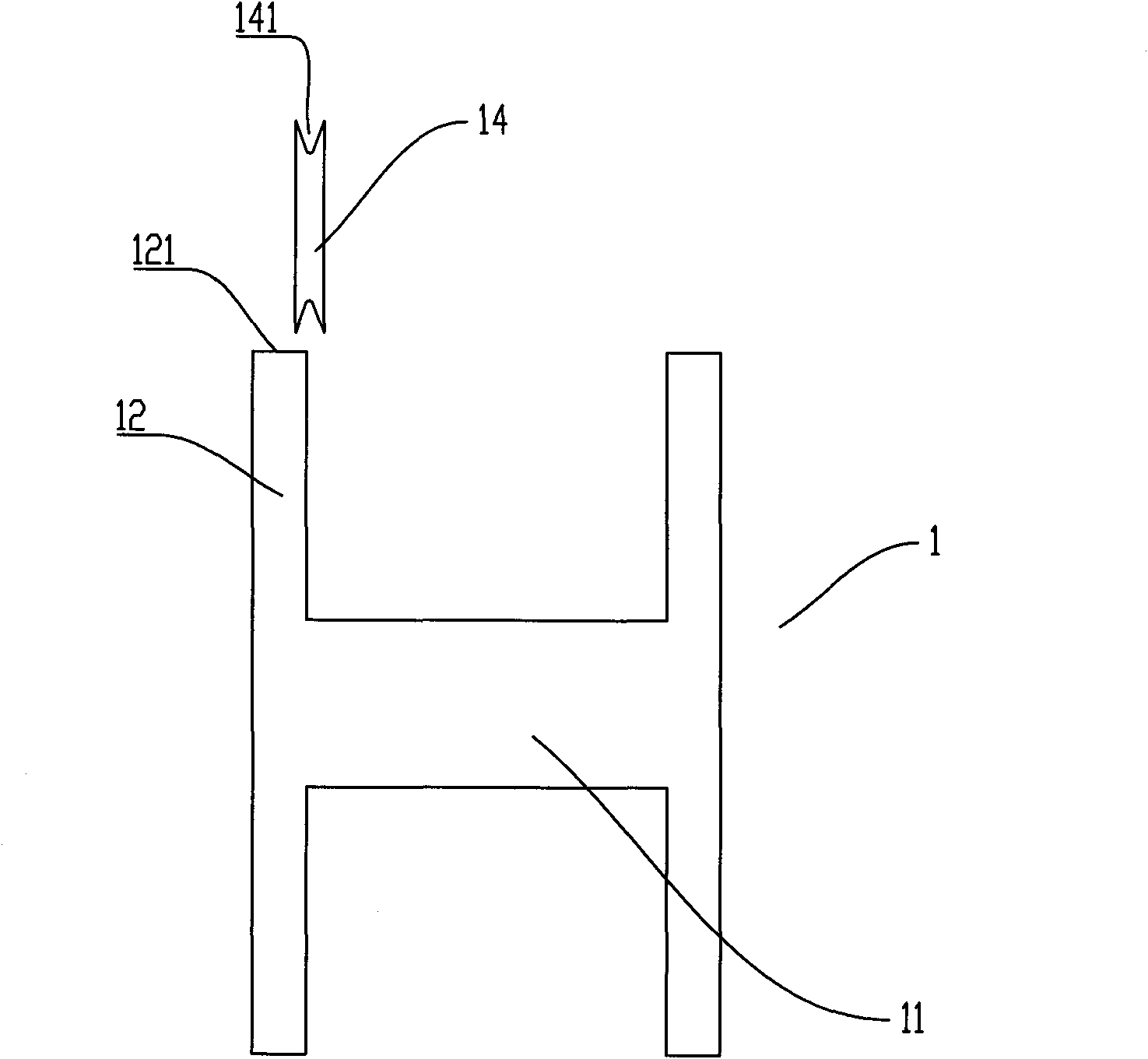

[0060] like Figure 5 Shown is the front view of the lead parts in the present invention, as Image 6 Shown is the top view of the present invention, Image 6 The three guide wheels are not shown.

[0061] The wire part includes a fixing frame 5, which is arranged in an arc shape, and the fixing frame 5 can half surround the wire reel 1. The two ends of the fixing frame 5 are divided into two sides of the wire reel 1.

[0062] A third threaded rod 53 and a fourth threaded rod 54 extending outward relative to the frame body are respectively installed at both ends of the fixing frame 5 .

[0063] A fifth screw rod 55 is arranged on the fixing frame 5 close to the third screw rod 53 , and a fifth nut 551 is mounted on the fifth screw rod 55 to cooperate with it.

[0064] A tensioner 56 is provided on the fixing frame 5 close to the fourth screw rod 54 , and the tensioner 56 is provided with an internal threaded hole (not shown in the figure) to cooperate with the screw 561 . ...

Embodiment 2

[0096] like Figure 16 Shown is the top view of the fixing frame in Embodiment 2. It differs from Embodiment 1 in that two thin sheets (111, 112) are used instead of steel wires. The thickness of the sheet can be determined according to actual work needs. The connection mode of the two thin sheets and the fixing frame is different from that of embodiment 1. A third threaded rod 53 and a fourth threaded rod 54 extending outward relative to the frame body are respectively installed at both ends of the fixing frame 5 .

[0097] Two third nuts 537 are arranged on the third screw rod 53 to cooperate with the third screw rod 53 , and the spacer 538 is sleeved on the third screw rod 53 . The two third nuts 537 are arranged on two sides of the spacer 538 .

[0098] Two fourth nuts 542 are arranged on the fourth screw rod 54 to cooperate with the fourth screw rod 54 . The spacer 543 is sleeved on the fourth screw rod 54 . The two fourth nuts 542 are arranged on two sides of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com