Lower-body structure for automobile

A vehicle body and automobile technology, which is applied to the superstructure, vehicle components, and superstructure sub-assemblies, etc., can solve the welding joint fracture, the inability to fully exert the restraint performance of the seat belt on the occupant, and the reduction of the N support performance of the fuel tank, etc. problem, to achieve the effect of high binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

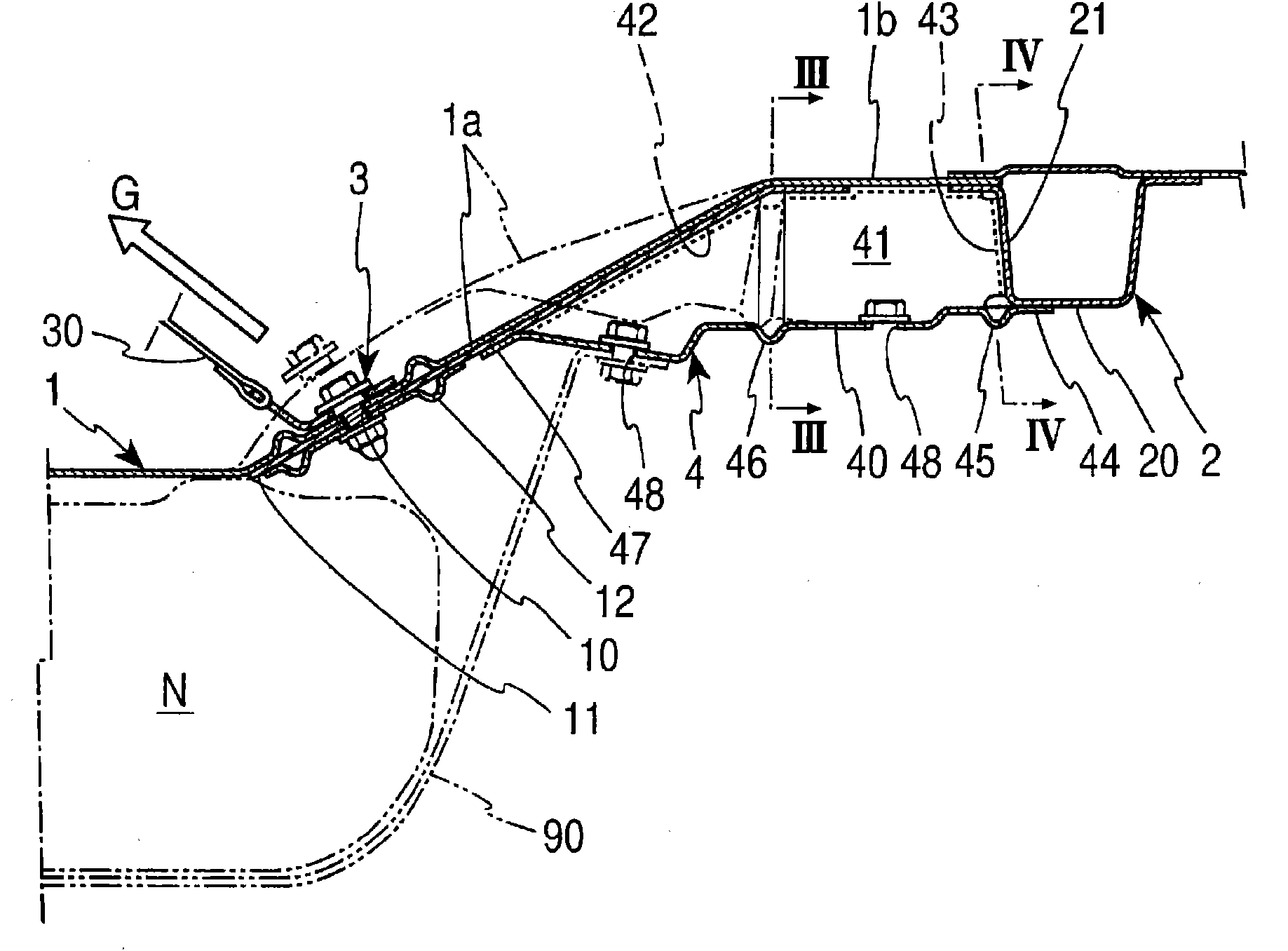

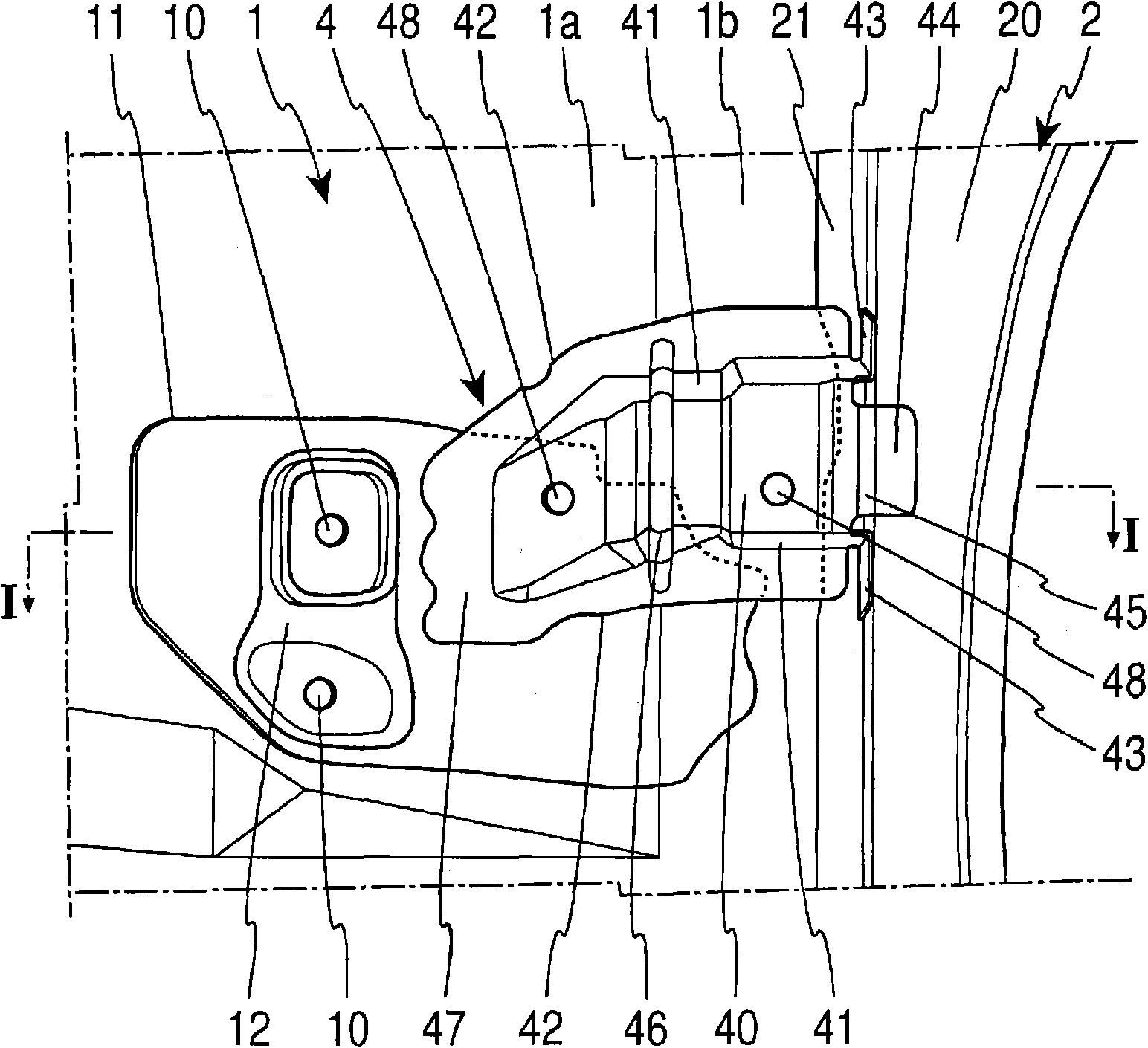

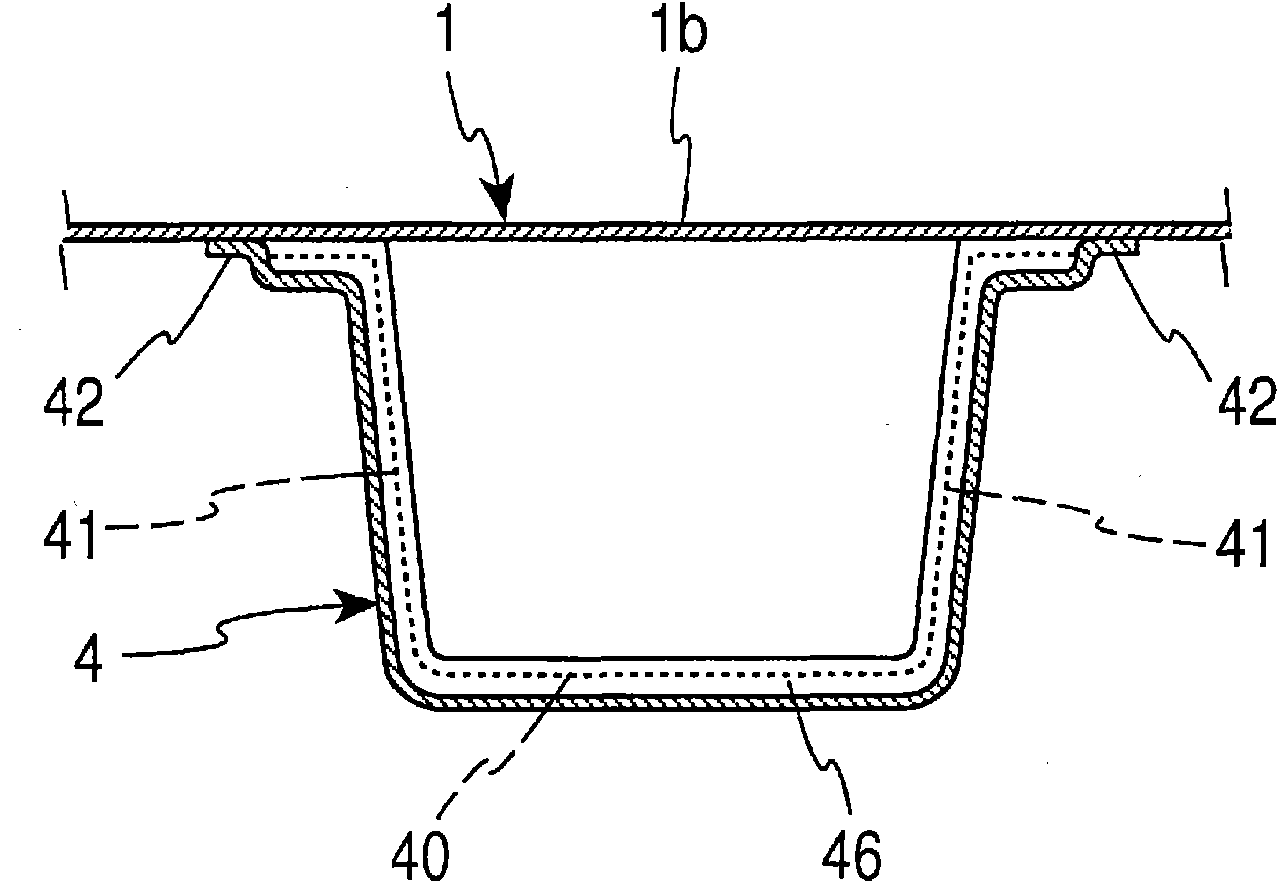

[0028] To apply the present invention to Figure 5 An embodiment of the floor 1 at the rear of the cab is shown for illustration. The basic structure of floor 1 is identical with existing structure in addition, as figure 1 As shown, on the floor 1, in the rear seat S ( Figure 5 ) and the installation position of the fuel tank N are formed with a front half 1a that extends slightly obliquely toward the rear and upward, and a horizontal flat shape that bends from the front half 1a and connects to the rear trunk floor that is one step higher. The second half of 1b.

[0029] Such as figure 1 , figure 2 As shown, the seat belt buckle 3 for the rear seat is fastened with bolts at a lower position near the front end of the front half 1a. The seat belt buckle 3 uses a metal plate with a substantially L-shaped cross section, and one piece is overlapped with the upper surface of the front half 1a, and is bolted into the coupling hole 10 of the front half 1a for coupling. A seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com