Automatic factory test method and device for servo driver

A servo drive and automatic detection technology, applied in the field of servo drives, can solve the problems of inability to detect servo drives, low product qualification rate, and many human factors, and achieve the effects of improving detection accuracy, precise parameter adjustment, and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

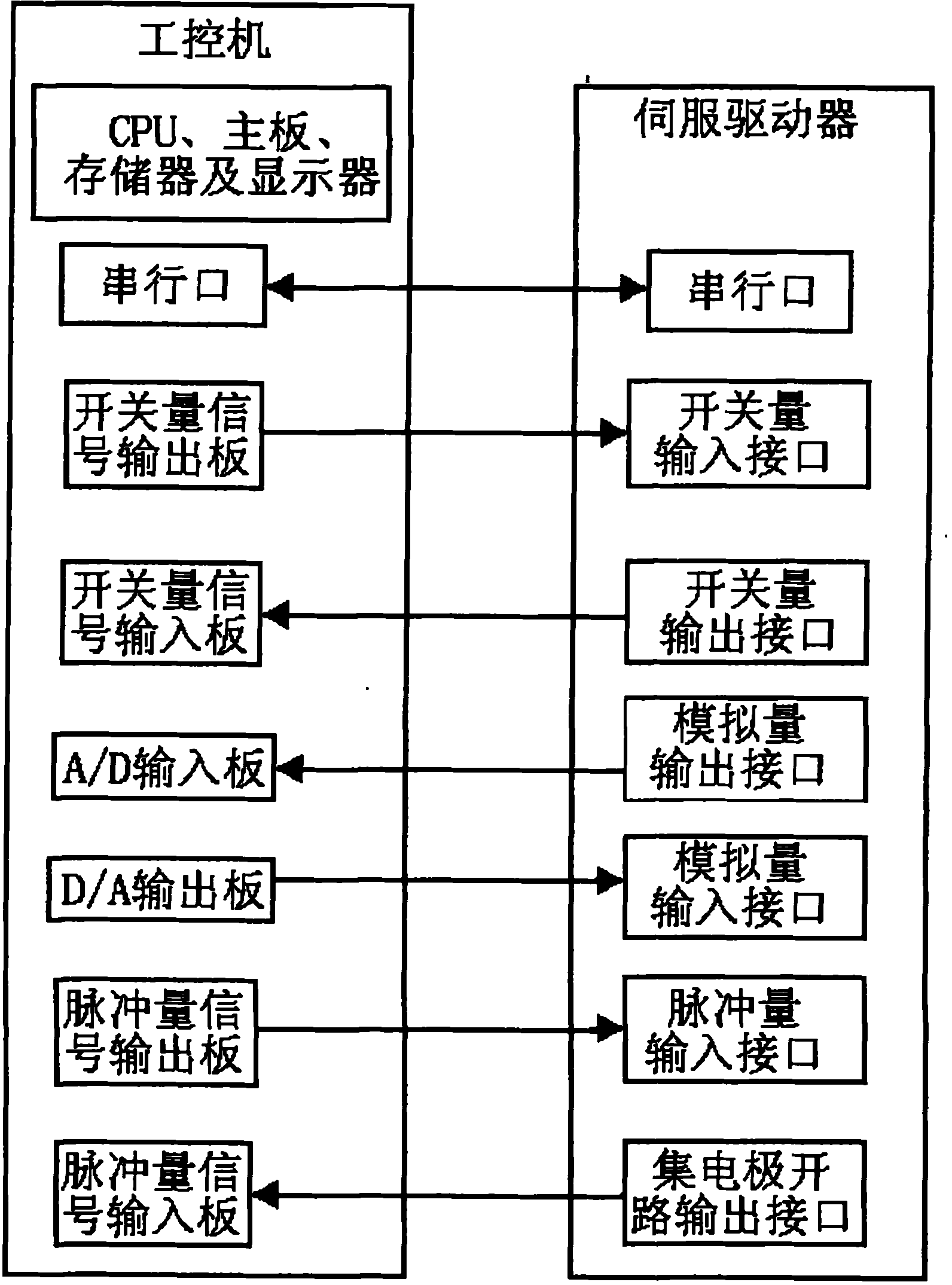

[0023] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

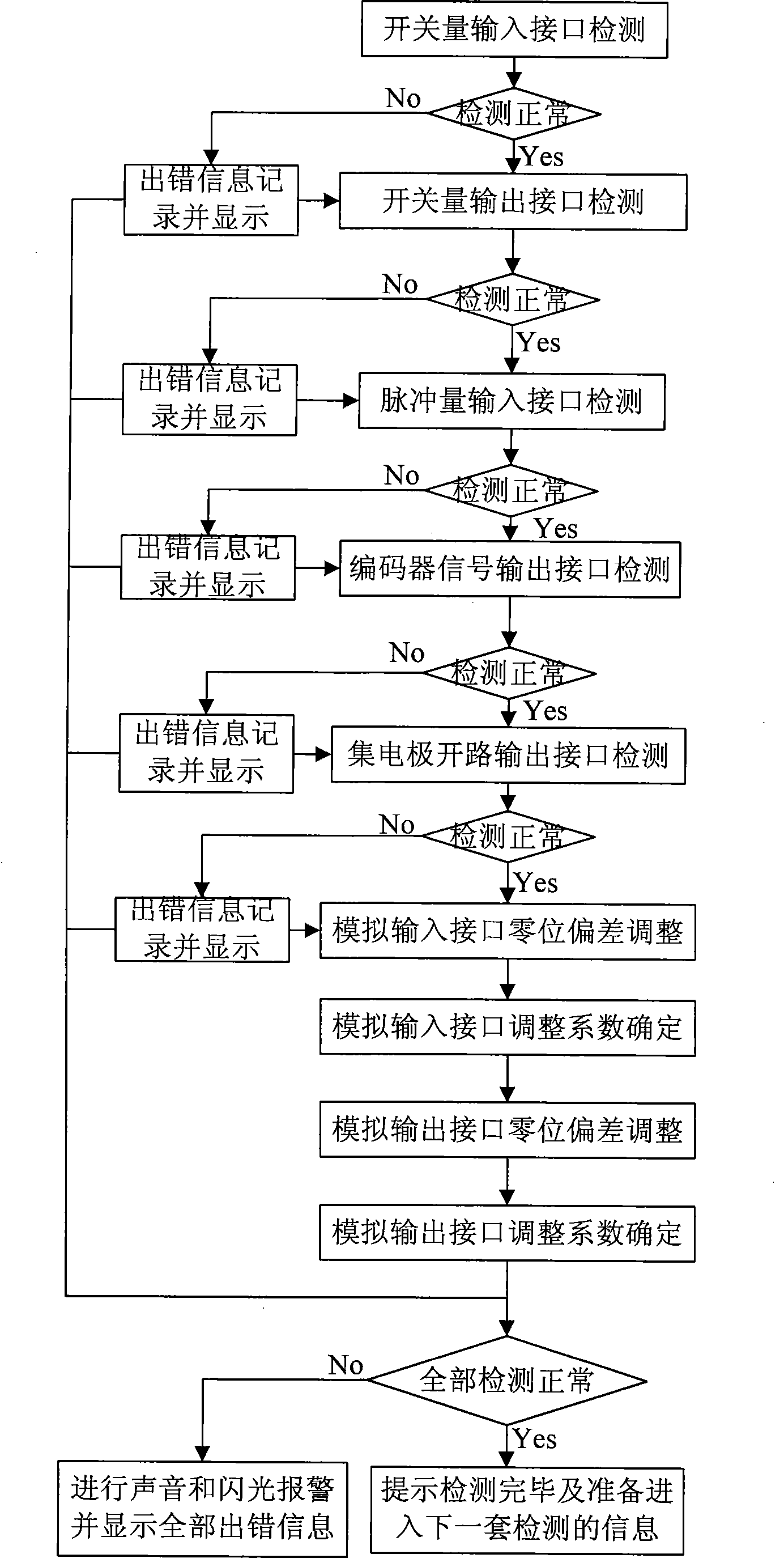

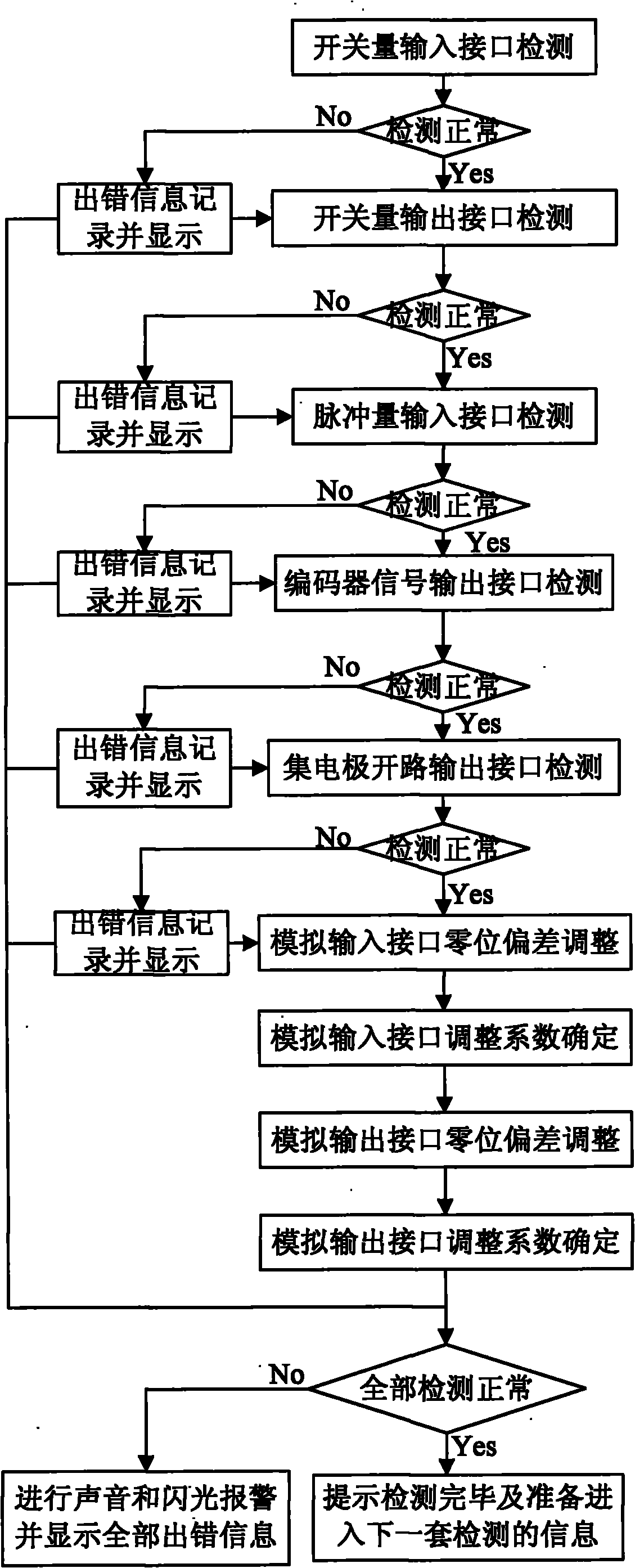

[0024] Such as figure 1 Shown, the present invention comprises the following steps:

[0025] 1) The detection step of the switching value input interface of the servo drive is used to detect whether the industrial computer of the servo drive controls the switching value signal output board to output high level or low level. If the level is consistent with the output level of the output board, that is, when both are low or high, it is judged that the switching value input interface of the servo driver is correct, otherwise it is judged that the switching value input interface is wrong. This step includes step 11 and step 12; step 11: The drive of the industrial computer is connected to the digital input interface of the servo driver. After a certain period of time after all the digital signals in the output board are at high level, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com