Oil-return control method of large-head long-piping heat pump air conditioning system

A heat pump air conditioning, oil return control technology, applied in heating mode, heating and ventilation control system, heating and ventilation safety system, etc. Affecting system operation and other problems, achieving the effect of good accuracy, thinning thickness, and ensuring oil return efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

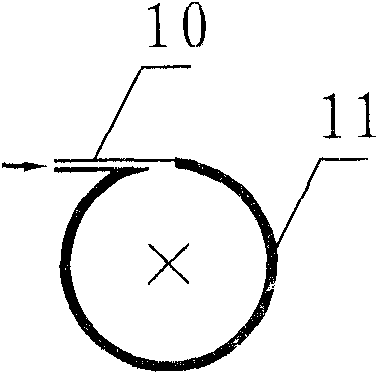

[0029] Embodiment 1: as figure 1 As shown, at the bottom of condenser (outdoor heat exchanger) 3 and evaporator (terminal heat exchanger) 6, and at the bottom of condenser (outdoor heat exchanger) 3 and compressor 1 suction pipe of the heat pump air conditioning system with high drop and long piping By-pass pipes 10 are installed between them; figure 2 , the bypass pipe 10 communicates with the refrigerant pipe 11 at the tangential position of the refrigerant pipe 11 at the bottom of the evaporator 6, and the bypass pipe 10 communicates with the lower part of the suction pipe at the tangential position of the suction pipe of the compressor 1; A solenoid valve 7 is installed on the bypass pipe 10 installed between the bottom of the evaporator 3 and the evaporator 6, the solenoid valve 7 is connected to the controller 9, and a flow sensor 8 is installed in front of the expansion valve 4, and the flow sensor 8 is connected to the refrigerant flow meter 5 , the controller 9 is c...

Embodiment 2

[0043] Embodiment 2: The system composition is the same as that of Embodiment 1, taking a direct expansion ground source heat pump with a cooling capacity of 5kW and a heating capacity of 4.5kW as a specific example. It is 12.7×1mm, and the buried depth is 25 meters. The specific operation steps of the oil return control method are as follows:

[0044] Step S 1 : Under heating conditions with an evaporation temperature of 5°C. The minimum refrigerant flow Gr of the heat pump air-conditioning system is preset to be 65.15Kg / h, and the normal operation time is T 1 2 hours, system oil return running time T 2 is 5 minutes;

[0045] Step S 2 : start up and enter the heating mode;

[0046] Step S 3 : Enter the normal running state and start recording the running time T;

[0047] Step S 4 : continuously monitor the refrigerant flow rate G of the heat pump air conditioning system;

[0048] Step S 5 : Compare the refrigerant flow G of the continuously monitored heat pump air-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com