Open-top composite clamp holder

A gripper, open technology, applied in the direction of drilling equipment, earthwork drilling, drilling tools, etc., can solve the problems of increasing auxiliary time and workload, restricting construction efficiency, troublesome putting process, etc., to achieve simple structure, open The effect of large volume and easy distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below with reference to the drawings and specific embodiments.

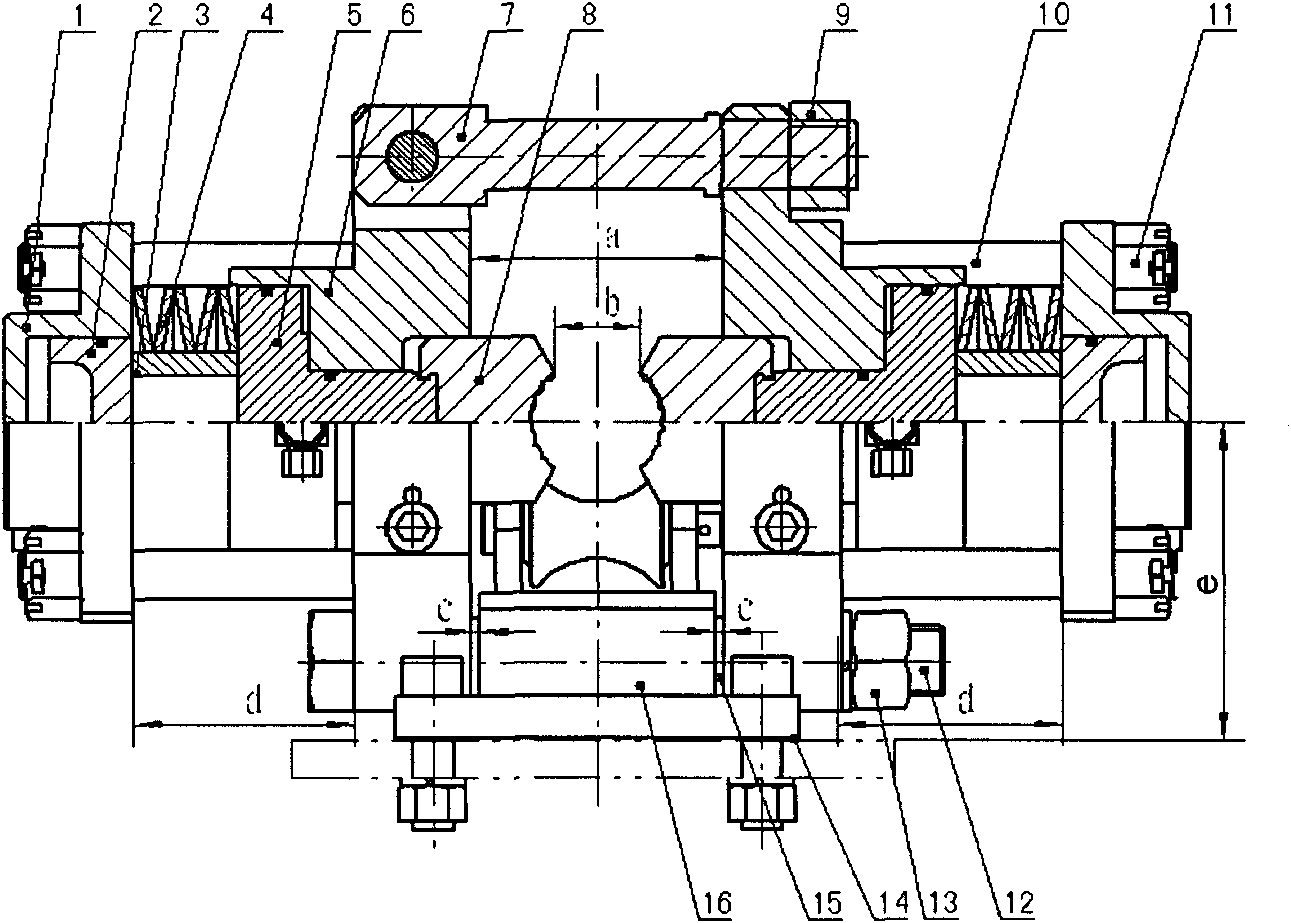

[0016] See figure 1 , 2 , The present invention adopts the open top symmetrical arrangement on both sides, including the main cylinder 6, the auxiliary cylinder 1, the disc spring 4, the top column 3, the upper rod 7, the slip 8, the sleeve 15, the base 16, the positioning tug 17, two main The cylinders 6 are symmetrically arranged at the two ends of the center of the holder. The main cylinder 6 is provided with a main cylinder piston 5, the auxiliary cylinder 1 is provided with a sub cylinder piston 2, and the slips 8 are provided in the main cylinder 6, and the main cylinder piston 5 is connected to the The disc spring 4 and the top post 3 are arranged between the auxiliary cylinder piston 2; the lower ends of the two main cylinders 6 are connected with the sleeve 15, the upper end is provided with an upper rod 7, the sleeve 15 is arranged on the base 16 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com