Water level control method for flush toilet water tank and water saving toilet

A technology for water level control and flushing toilets, applied in flushing toilets, flushing equipment with water tanks, water supply devices, etc., can solve problems such as trouble for users, and achieve the effects of low equipment damage, low manufacturing cost, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

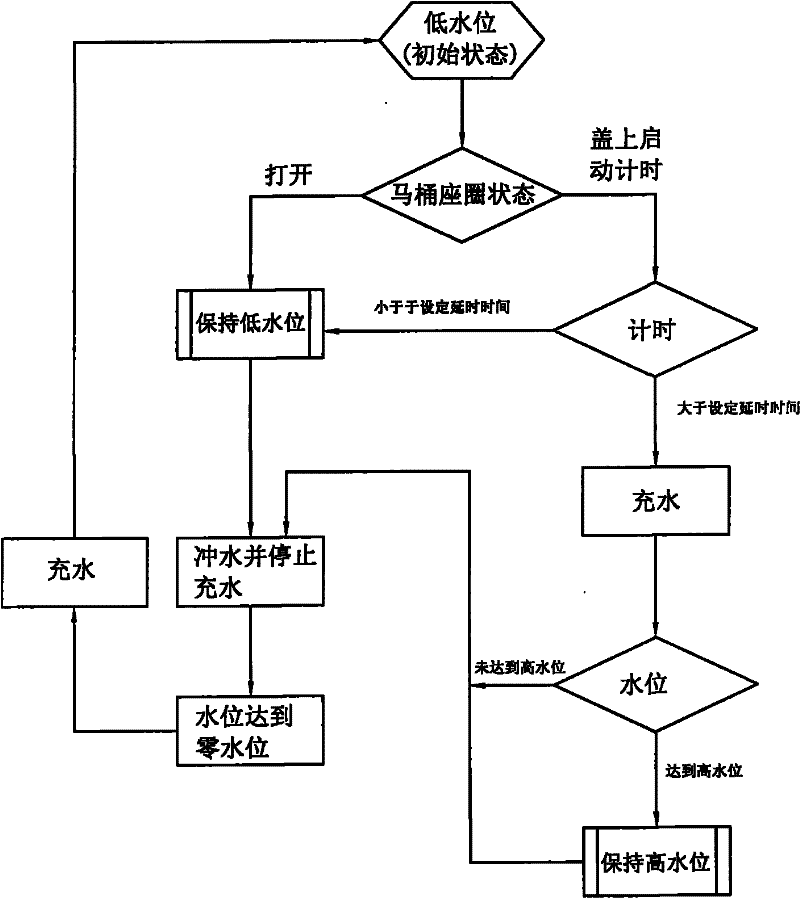

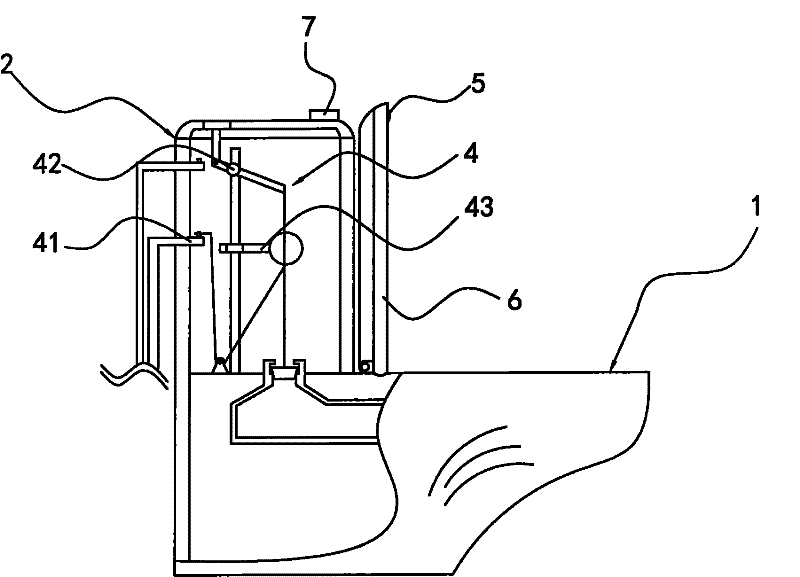

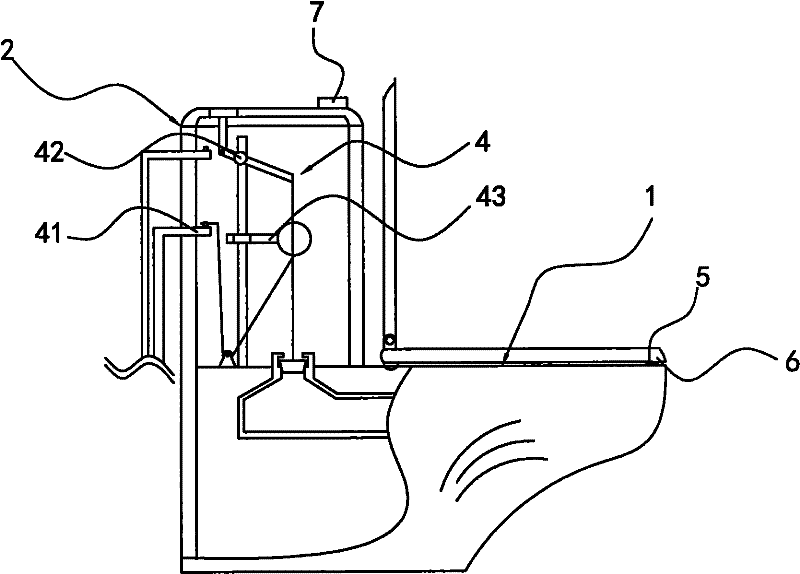

[0028] Embodiment one: if figure 1 , figure 2 As shown, the main structure of this embodiment mainly includes the toilet main body 1, the water tank 2 and the water inlet, drainage and water level control mechanism 4 in the water tank 2, and the water inlet, drainage and water level control mechanism 4 includes the water inlet mechanism 41, Drain mechanism 42 and water level control mechanism 43 three parts. A water filling switch 5 is arranged on the toilet seat 6, the water filling switch 5 is an infrared sensor switch, and a delayer 7 is connected to the water filling switch 5. The delay device 7 is controlled by the water filling switch 5 to start, and when the water filling switch 5 starts, the delay device 7 begins to record the delay time length of the flushing switch 5 starting the water filling device 41 to start filling water; when the flushing switch 5 is closed or Delay device 7 returns " zero " with the recorded delay time when disconnecting. Because some user...

Embodiment 2

[0035] Embodiment two: if figure 2 As shown, the structure of this embodiment is the same as that of Embodiment 1, the difference is that the delay time of the delayer is 4 minutes. The interval between two adjacent connections of the water filling switch 5 is less than 6 seconds, and the delayer 7 does not return to "zero".

[0036] The water storage capacity of the low water level of the water tank 2 is 35% of the high water level storage capacity.

Embodiment 3

[0037] Embodiment three: as figure 2 As shown, the structure of this embodiment is the same as that of Embodiment 1, the difference is that the delay time of the delayer is 2 minutes. The interval between two adjacent communication of the flush switch 5 is less than 8 seconds, and the delayer 7 does not return to "zero".

[0038] The water storage capacity of the low water level of the water tank 2 is 45% of the high water level storage capacity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com