Built-in buoy towing barrel-shaped foundation sinking method

A barrel-shaped foundation and buoy technology, which is applied in infrastructure engineering, caisson, construction, etc., can solve problems such as difficulty in recycling built-in buoys, and achieve the effects of safe and effective sinking into place, convenient recovery of buoys, and simple methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

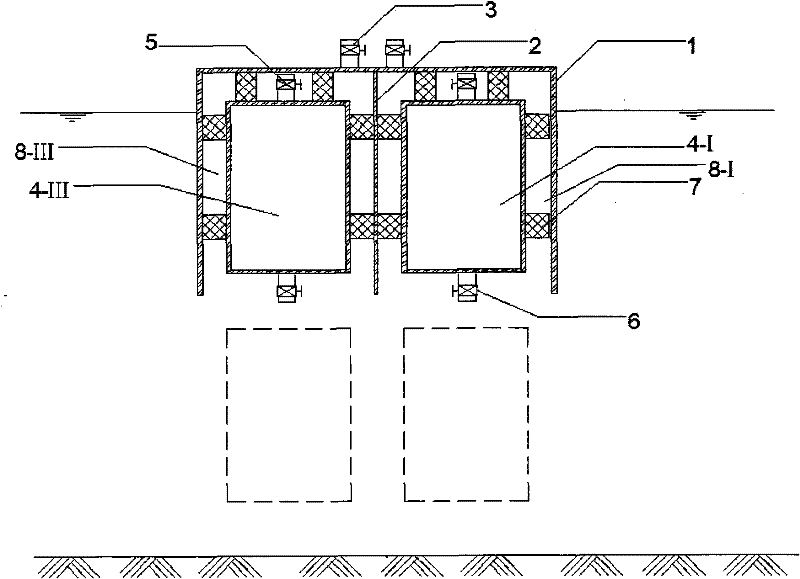

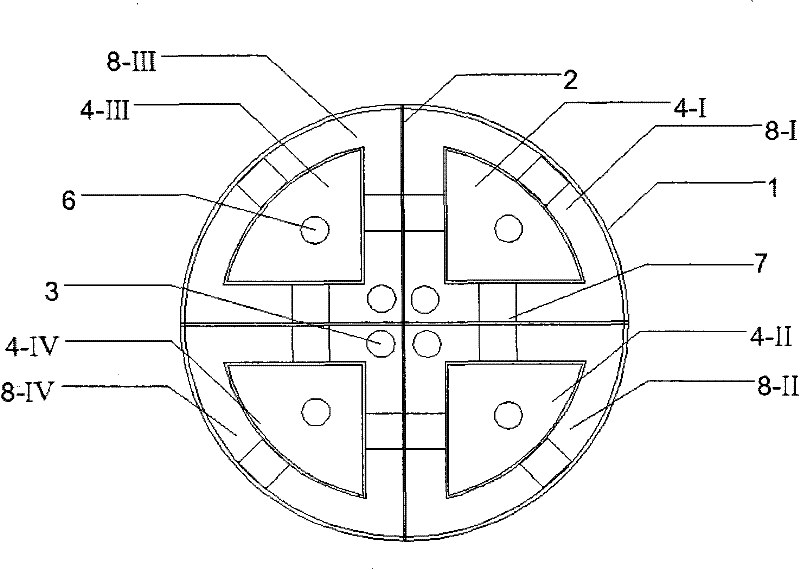

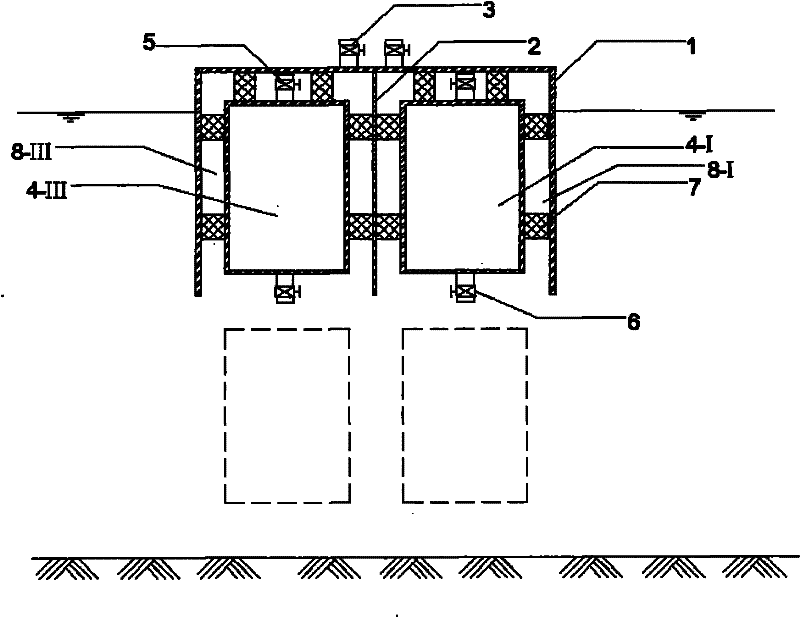

[0014] A method for sinking a cylindrical foundation with built-in buoy towage. The cylindrical foundation 1 is divided into four compartments 8-I, II, III, and IV with fan-shaped cross-sections through a bulkhead 2. There is a discharge control valve 3, at least one is provided in each cabin, and the buoy is arranged inside the cylindrical foundation 1. The buoy also adopts a split structure, which consists of four phases with the cylindrical foundation 1 cabin 8-I, II, III, IV. Matching buoys 4-I, II, III, IV are formed, each sub-pony 4-I, II, III, IV top is provided with an exhaust valve 5, each sub-pony 4-I, II, III, IV bottom A drain valve 6 is provided, and a vibration isolation pad 7 is provided between the sub-pontoons 4-I, II, III, IV and the cylindrical foundation 1; after the cylindrical foundation 1 is towed in place, the built-in sub-pontoons 4-I, II , III, and IV are provided with the exhaust valve 5 and the drain valve 6, and the air in the sub-floor 4-I, II, II...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com