Preparation method of ammonium phosphate anti-caking

An ammonium phosphate and anti-caking technology, which is applied in the field of phosphate fertilizers, can solve the problems of ammonium phosphate fertilizers caking and other problems, and achieve the effects of improving the viscosity of slurry, facilitating growth, and improving anti-caking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

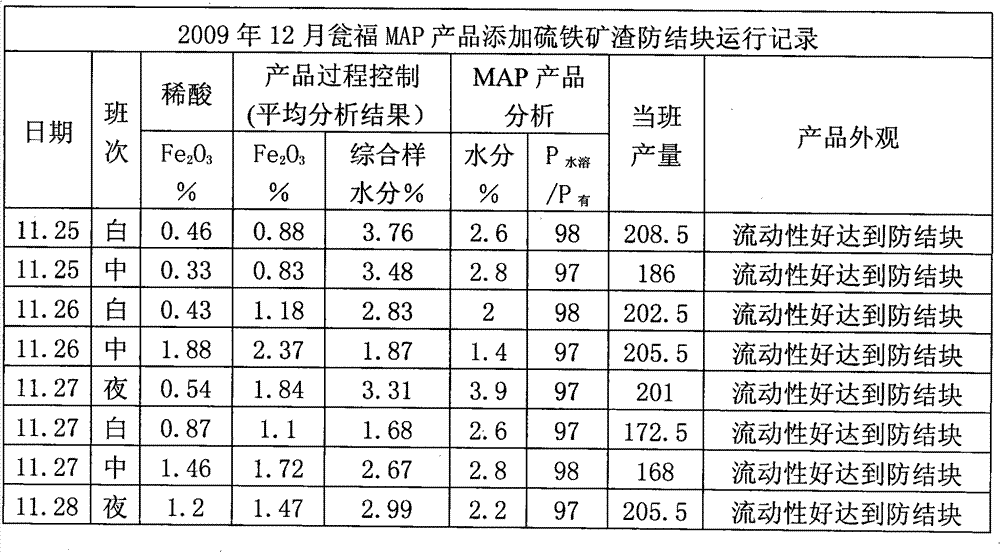

[0013] The present invention has been applied in the Wengfu Phosphate Fertilizer Plant of Wengfu (Group) Co., Ltd., where the pyrite slag produced by the 800,000-ton / year pyrite acid plant is used in the 360,000-ton / year monoammonium phosphate plant , the effect is good.

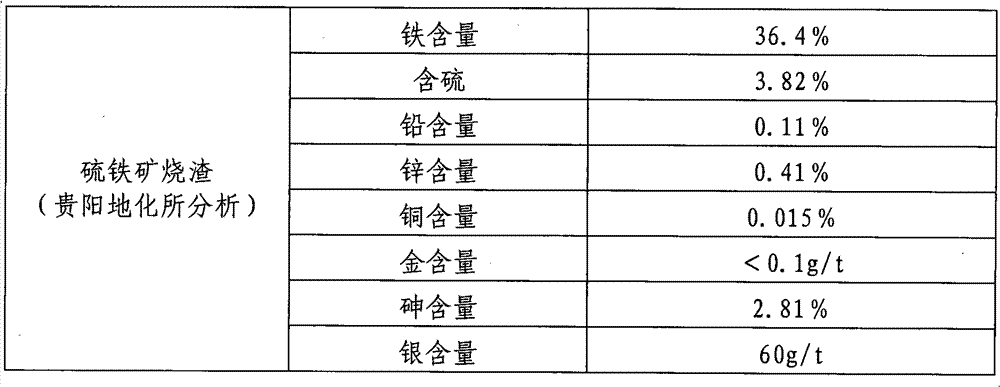

[0014] Based on the analysis data of pyrite slag on October 20, 2009, it is as follows:

[0015]

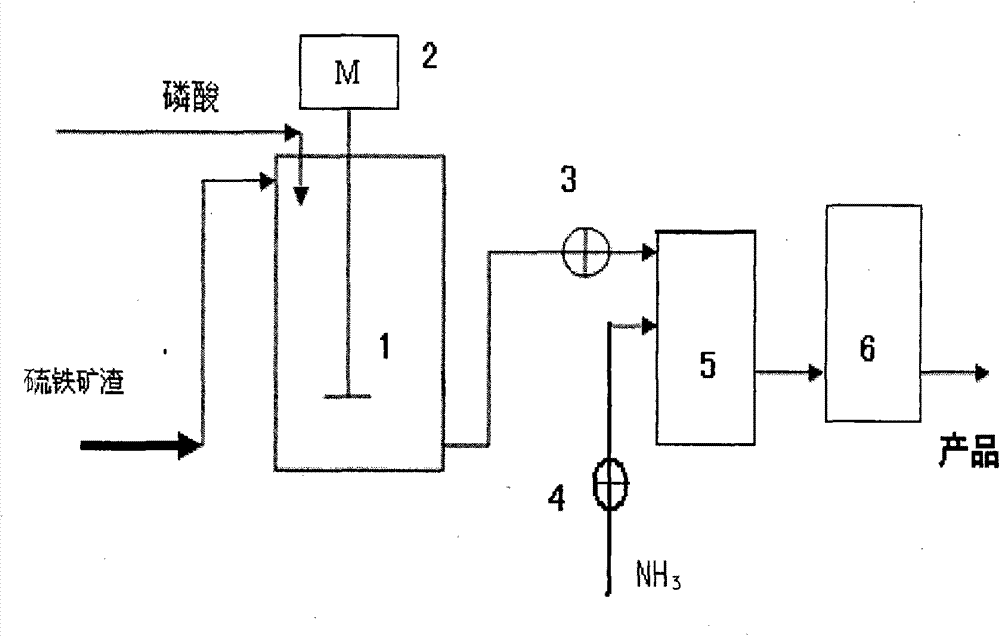

[0016] First, the pyrite slag is ground into a fine powder with a particle size of 0.01 mm to 1.0 mm, and then in the ammonium phosphate production device, the slag fine powder is added to the raw material for ammonium phosphate production in a proportion of 10%—the mass fraction is 25 % in the dilute phosphoric acid storage tank, the addition amount is controlled at 5t / h, and the amount of phosphoric acid is 50m 3 / h to improve the viscosity of the slurry; stir continuously with a stirrer in the storage tank, mix evenly and transport it to the neutralization reactor with a pump, the reaction between phosph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com