Thick and thin bag production device

A production device and thickness technology, applied in the field of plastic film bag manufacturing, can solve the problems of affecting strength, uneven wall thickness, fast cooling speed, etc., and achieve the effect of improving the ratio of thickness to thickness, good strength and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

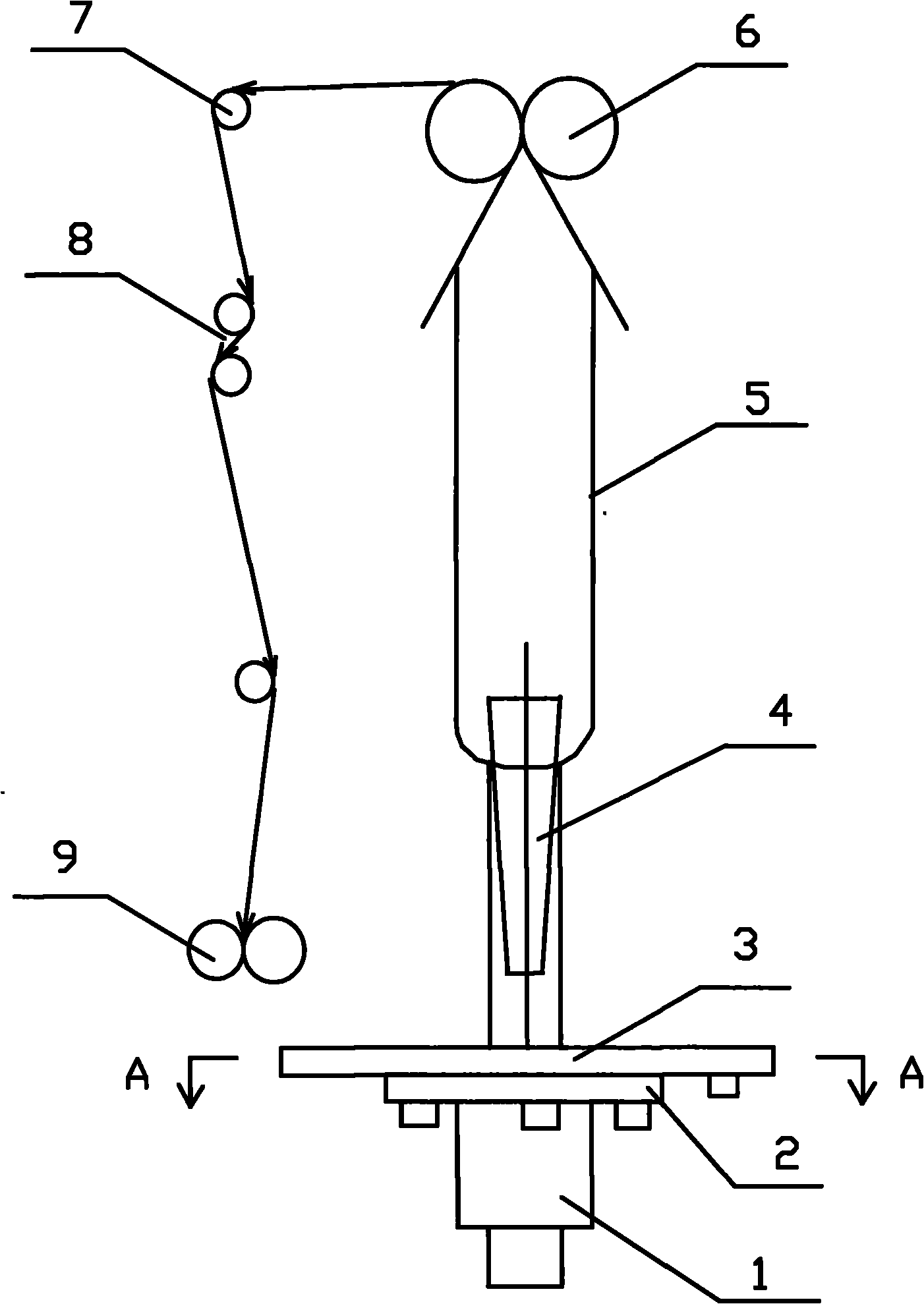

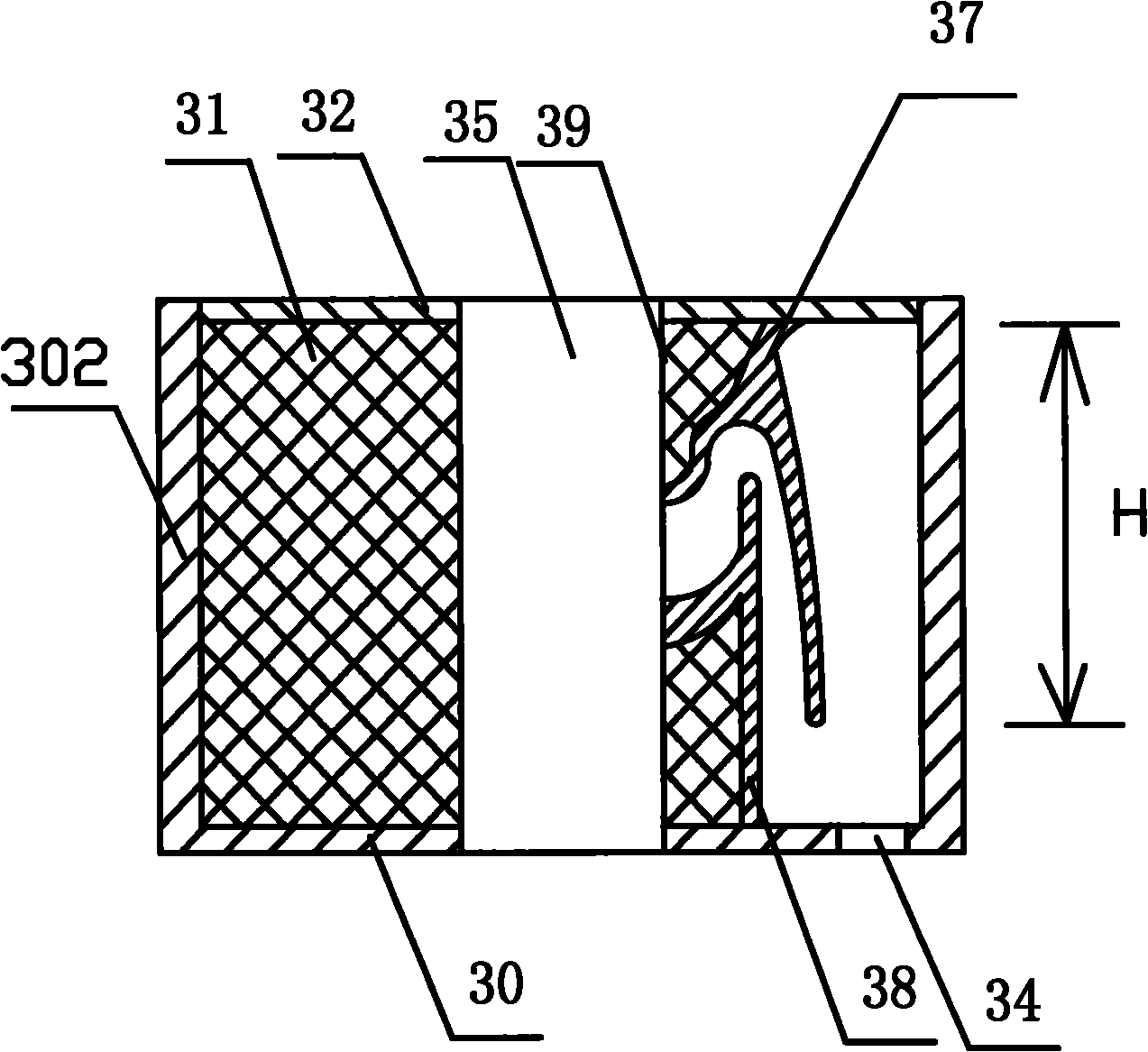

[0020] Such as figure 1 As shown, the thick and thin bag production device of the present invention includes an extruder, a die head 1, a standard air ring 2, a mold air ring 3, an upper traction roller 6, a guide roller 7, a corona processor 8, and a winder 9. The extruder is driven by a motor and is used to squeeze and heat the plastic to melt it into a fluid state. The die head 1 is connected with the discharge port of the extruder, and the molten plastic is extruded from the discharge ring gap of the die head 1 . The upper end of the die head 1 is provided with a standard air ring 2, and the standard air ring 2 blows the molten plastic into a rough blank 4 of a film bubble. The upper end of the standard air ring 2 is fixedly connected to the mold air ring 3. There is a through hole 35 in the middle of the mold air ring 3 for the rough blank 4 to pass through. The mold air ring 3 is used to control the wall thickness of the thick side of the rough blank 4. Above the mold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com