Stone edge automatic grinding and polishing machine

A technology for grinding and polishing machines and stone materials, applied in grinding/polishing equipment, machine tools suitable for grinding workpiece edges, grinding machines, etc. The effect of improving efficiency and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below with reference to the accompanying drawings.

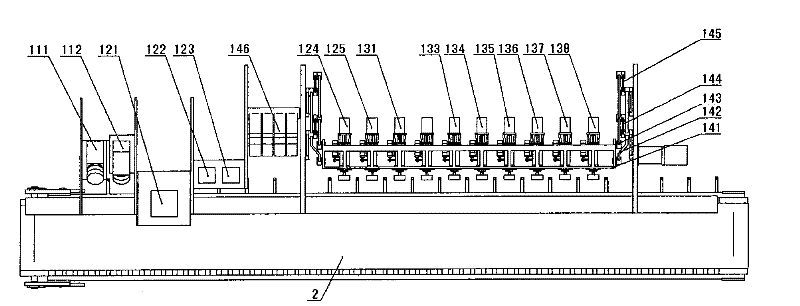

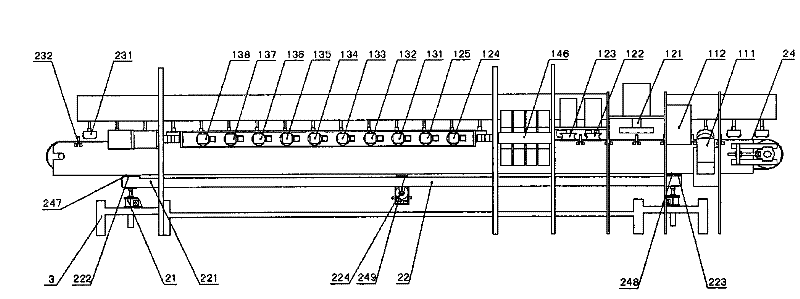

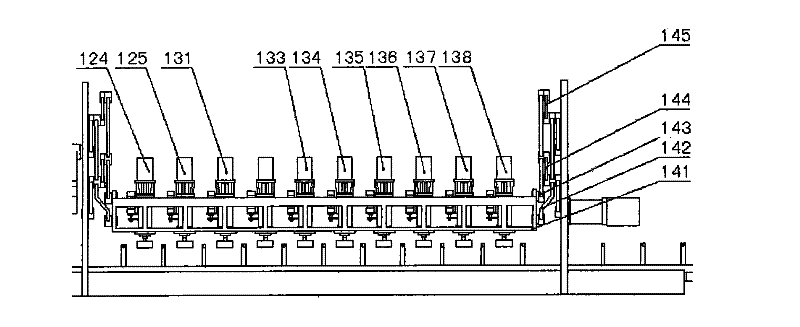

[0033] The stone edge automatic grinding and polishing machine adopts an assembly line structure, figure 1 It is the top view of the stone edge automatic grinding and polishing machine of the present invention, figure 2 It is the rear view of the stone edge automatic grinding and polishing machine of the present invention, Figure 7 It is a three-dimensional reference schematic diagram of the stone edge automatic grinding and polishing machine of the present invention.

[0034] This equipment can be divided into three parts: processing head group, processing parts conveying line 2, frame 3. Four interlocking worm gear screw lifts 21 are installed on the stone material sideline automatic grinding and polishing machine frame 3, as a vertical positioning device, to realize the vertical positioning of the conveying platform. The support of worm wheel screw lifter 21 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com