Loading table structure and processing device

A mounting table and structure technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as increased operating costs, leakage of purge gas, and difficult process execution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

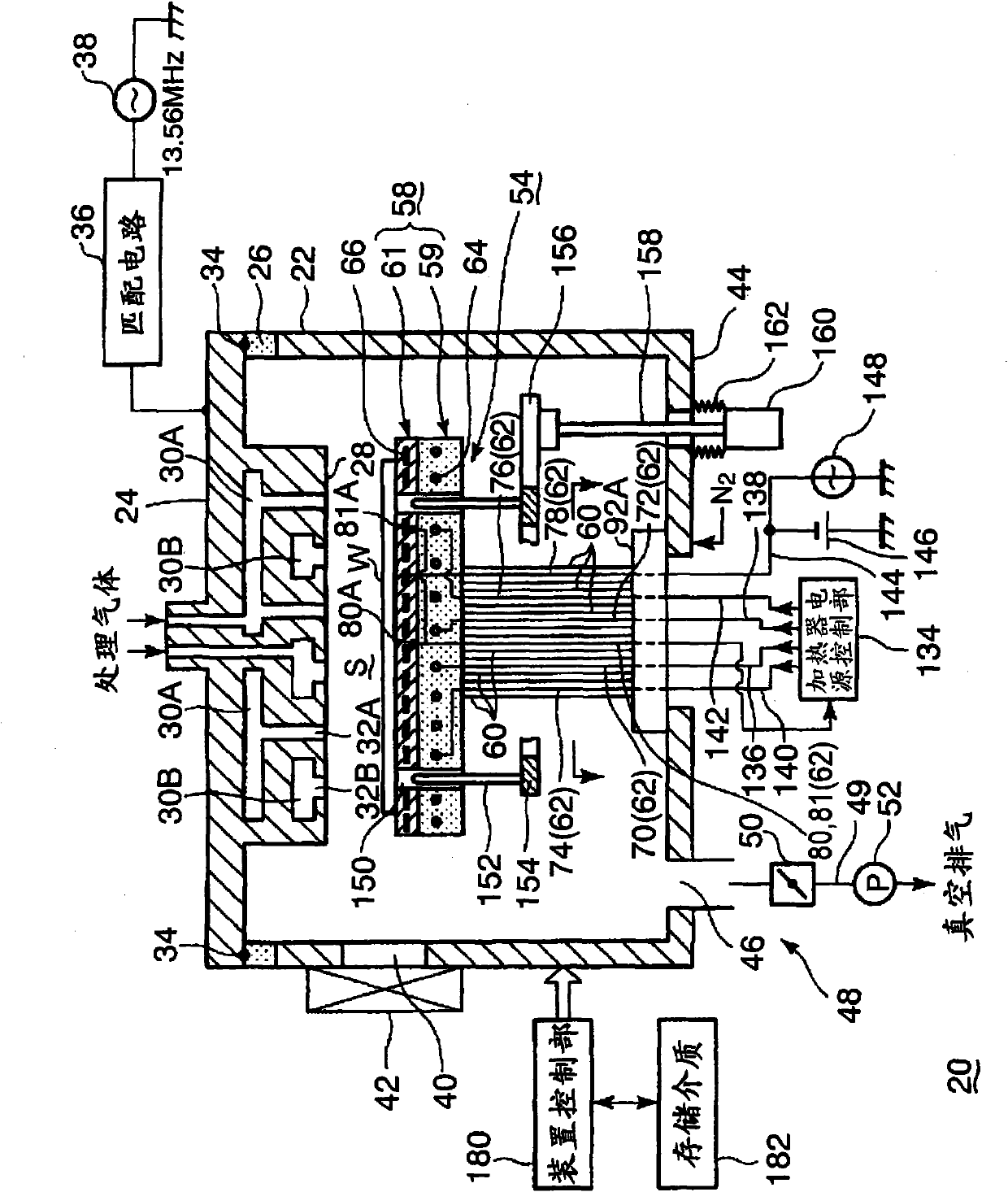

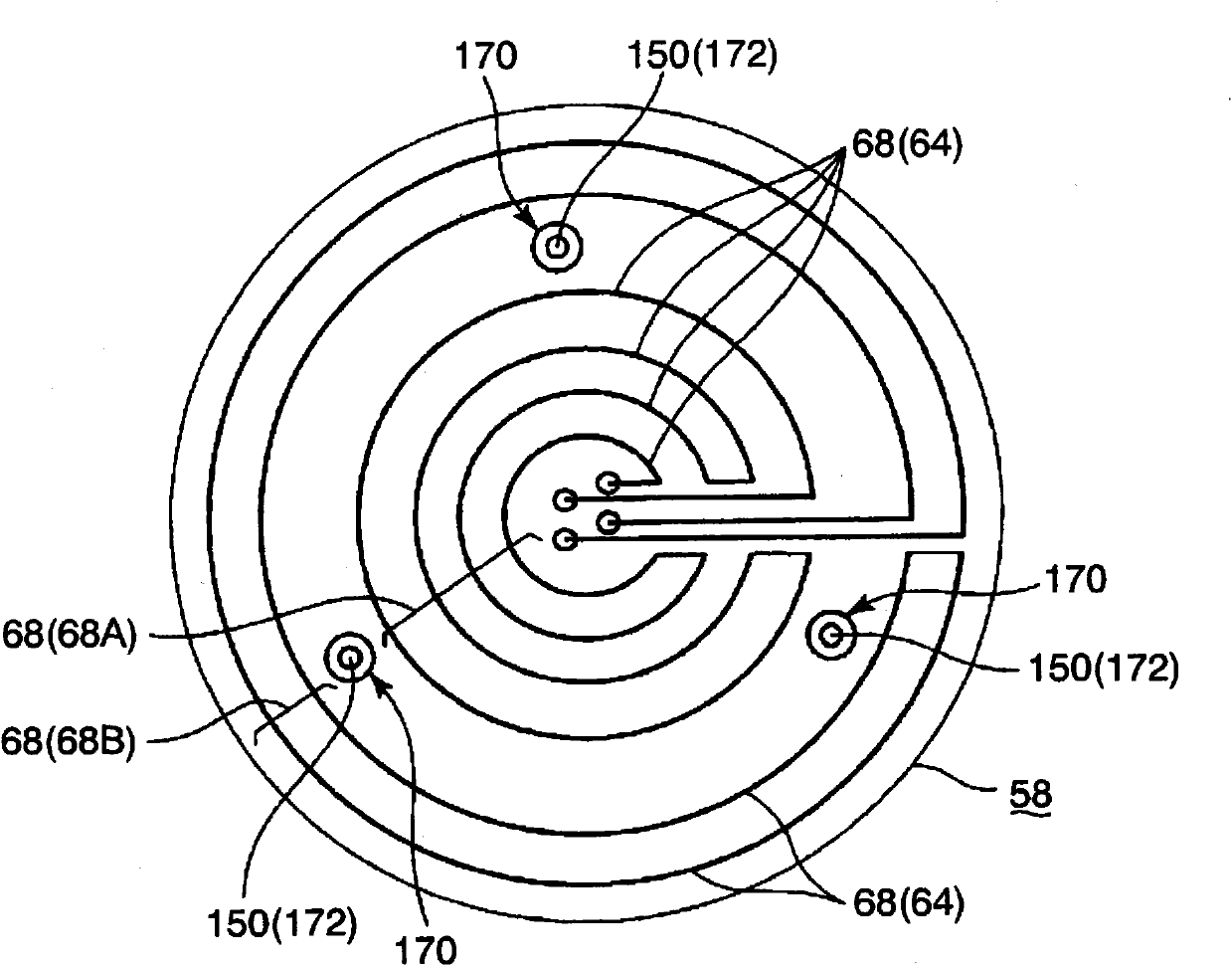

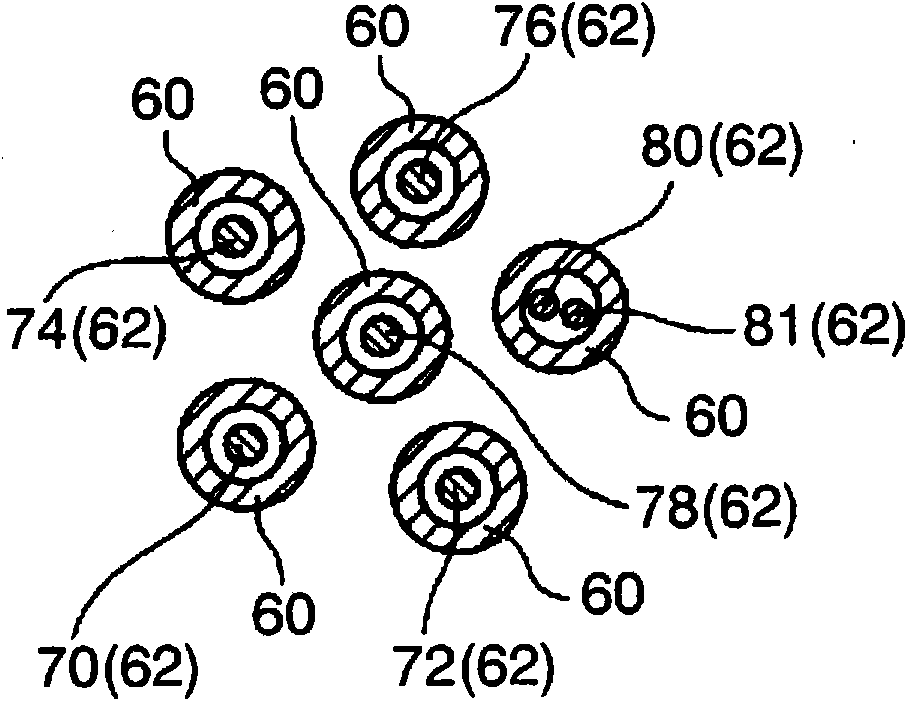

[0145]However, in each of the above-described embodiments, the process gas for film formation surrounds the back side of the mounting table 58 during film formation, and the processing gas enters the pin insertion holes 150 formed in the mounting table bolts 170 . Here, when the wafer W is placed on the stage 58, in order to suppress misalignment, the inner diameter of the pin insertion hole 150 is made, for example, about 4 mm, and the diameter of the push-up pin 152 is made, for example, about 3.8 mm to reduce the pin insertion size. The gap between the through hole 150 and the push pin 152 . Accordingly, when the processing gas for film formation enters the pin insertion hole 150 , the thin film accumulates little by little in the inside, which hinders the lifting operation of the lift pin 152 . Therefore, it is necessary to regularly or irregularly perform dry etching and wet etching to perform frequent cleaning operations, and in this case, there is a problem of lowering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com