Lens refractive index and thickness measuring method and device based on differential confocal technology

A differential confocal and measurement method technology, which is applied in the direction of measuring devices, optical devices, and testing optical properties, can solve the problems of not being able to measure the thickness of lens samples, cumbersome calculations, and low measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0068] In this embodiment, the refractive index and thickness of the GCL-0101 K9 plano-convex lens are measured.

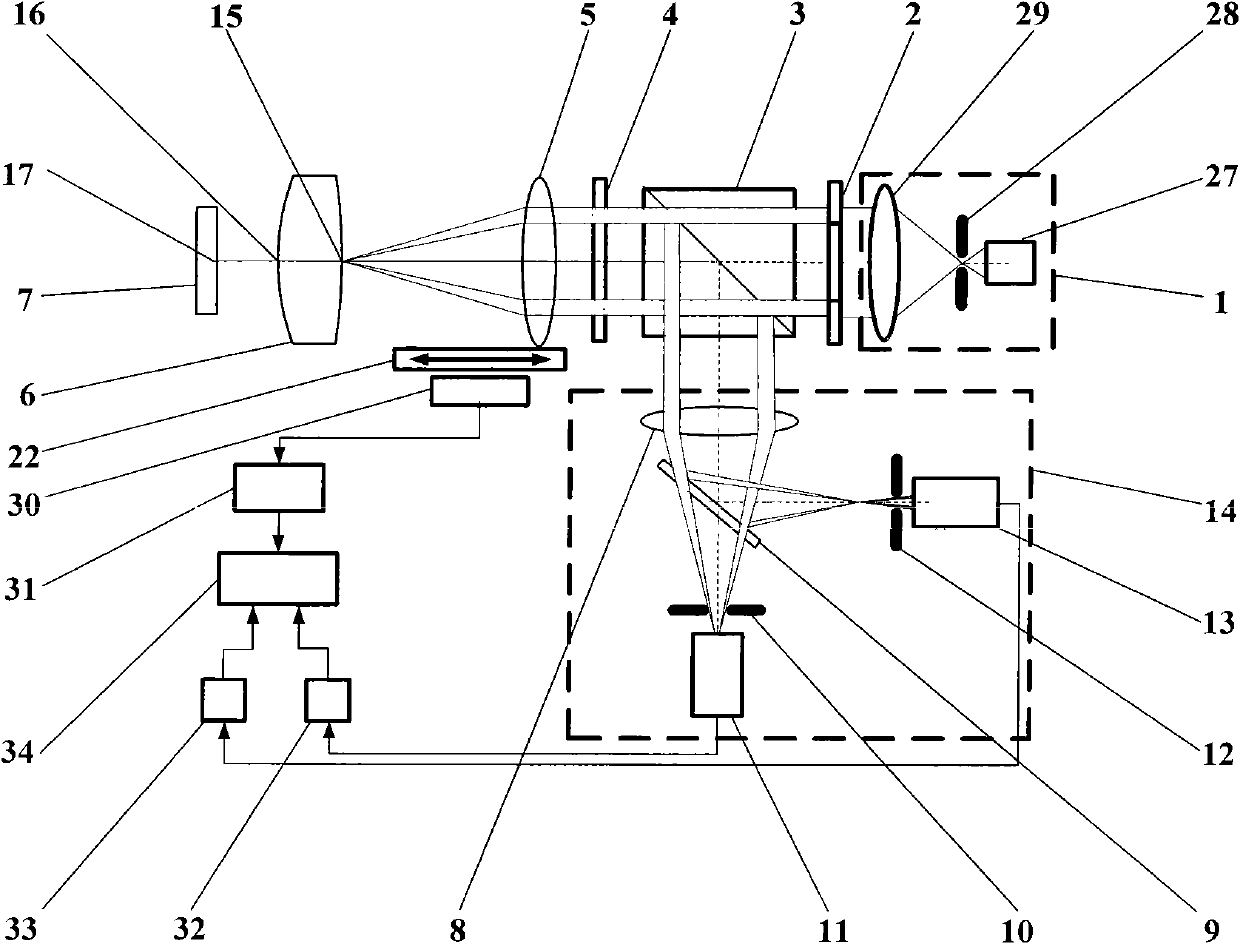

[0069] A measuring device for lens refractive index and thickness based on differential confocal technology, such as figure 1 As shown, it includes: light source 1, measured lens 6, annular pupil 2, polarization beam splitting system 3, λ / 4 glass slide 4, measuring mirror 5, reflecting mirror 7, differential confocal system 14, data processing system 34, Signal filtering and amplifying device A32, signal filtering and amplifying device B33, displacement information processing device 31, displacement measuring device 30, measuring mirror driving device 22; light source 1 is a He-Ni laser 27 with a wavelength of 632.8nm; semiconductor laser 27, light source needle Aperture 28, collimating lens 29; differential confocal system 14 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com