Coiled parallel flow condenser for refrigerator

A condenser and parallel flow technology, which is applied in the direction of evaporator/condenser, refrigerator, refrigeration components, etc., can solve the problems of difficult product manufacturing, difficult installation of condenser, and less refrigerant filling, and achieves compact structure, The effect of less refrigerant charging and less consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

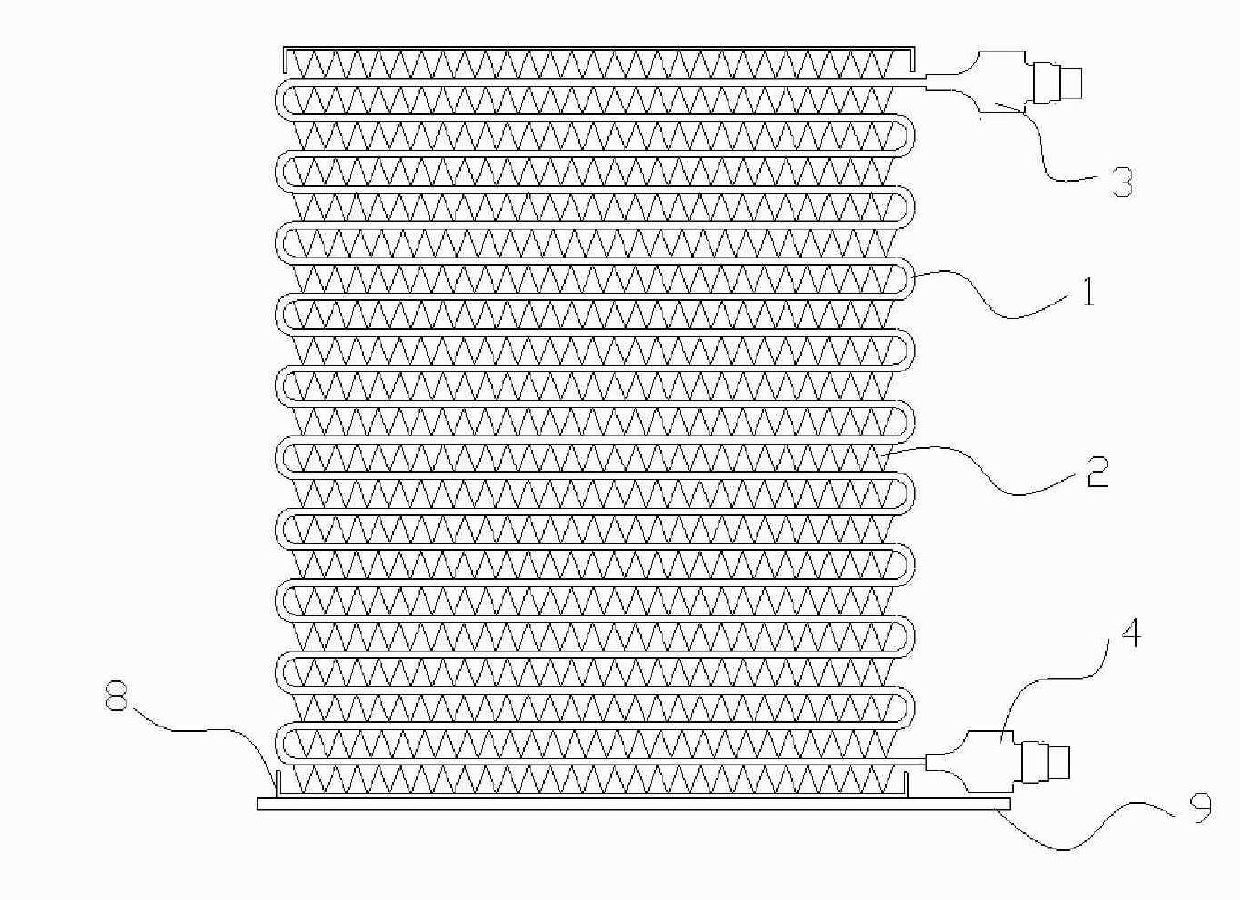

[0023] see figure 1 , 2 , the flat tubes 1 are bent into serpentine tubes, and heat sinks 2 are arranged between adjacent serpentine flat tubes. The upper and lower ends of the flat tubes 1 are respectively connected with a heat sink 2, and the side plates 8 are connected to the heat sink 2 connection to protect the heat sink. One end of the serpentine flat tube 1 is connected with the inlet tube assembly 3 , and the other end of the serpentine flat tube 1 is connected with the outlet tube assembly 4 .

[0024] Such as image 3 As shown, the inlet pipe assembly 3 and the outlet pipe assembly 4 are formed by copper-aluminum resistance welding of the copper pipe 6 and the special joint 5, and a radiation cross-linked heat shrinkable sleeve 7 is arranged at the welding place.

[0025] see Figure 4 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com