Device for displacing oil underground, preventing reflow and automatically relieving pressure

An automatic drainage and oil displacement technology, which is applied to wellbore/well valve devices, wellbore/well components, earthwork drilling and production, etc., can solve the problems of increasing economic investment in operation procedures, and achieve simple structure, long service life, The effect of saving workover cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

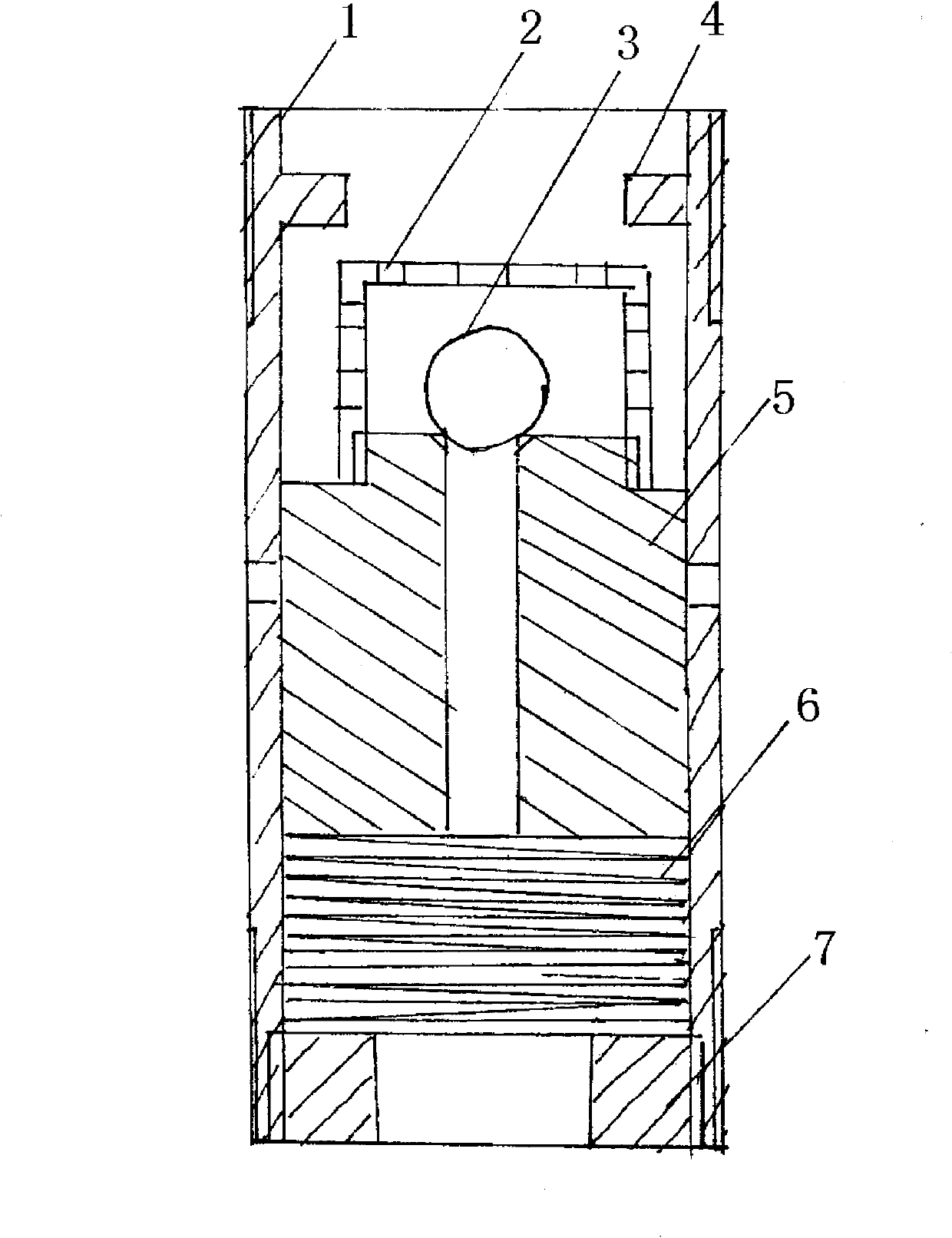

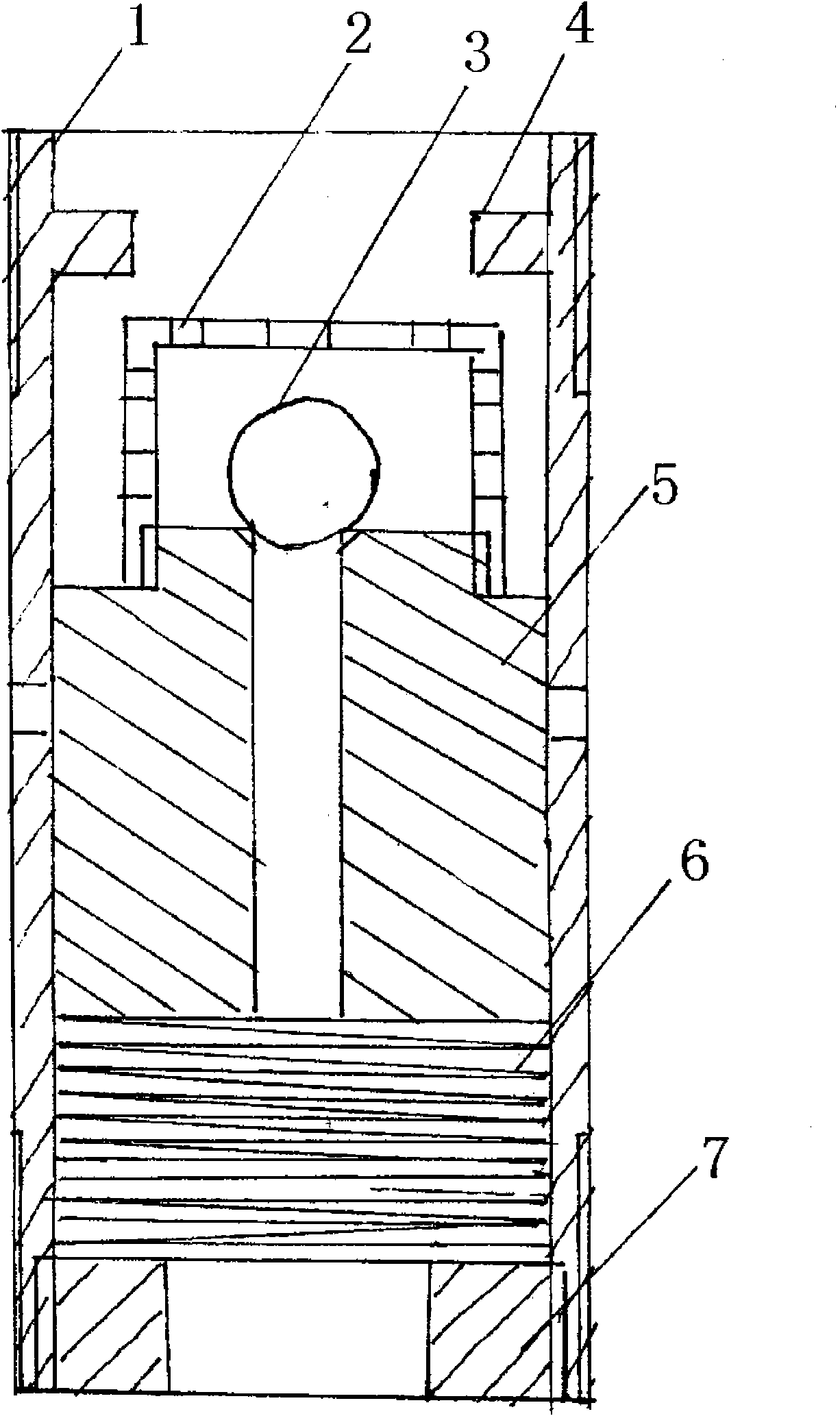

[0010] In order to further disclose the technical solutions of the present invention, the following will be described in detail through examples in conjunction with the accompanying drawings:

[0011] The present invention is mainly composed of a body 1, a sealing ball cover 2, a sealing ball 3, a slider 5, a spring 6, a limit block 4 and a spring seat 7. Thread, the inner circumference of the upper part is provided with a number of limit blocks 4, the inner circumference of the lower part is provided with female threads, and the center of the upper end with a sealing ball cover 2 is provided with a core hole and the upper part of the center hole is provided with a sealing ball 3 in the middle of the body. The cylindrical slider 5 has a coil spring 6 at the middle and lower part, and a spring seat 7 threadedly connected with the body at the lower part, and several oil drain holes are arranged at the middle part of the body; the dynamic sealing fit between the slider and the bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com