Preparation method of perfluorinated high-temperature proton-conductor composite membrane

A proton conductor and composite membrane technology, which is applied in fuel cell parts, fuel cells, structural parts, etc., can solve problems such as the decrease of methanol permeability, and achieve the effects of avoiding pollution, low cost of phosphoric acid, and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

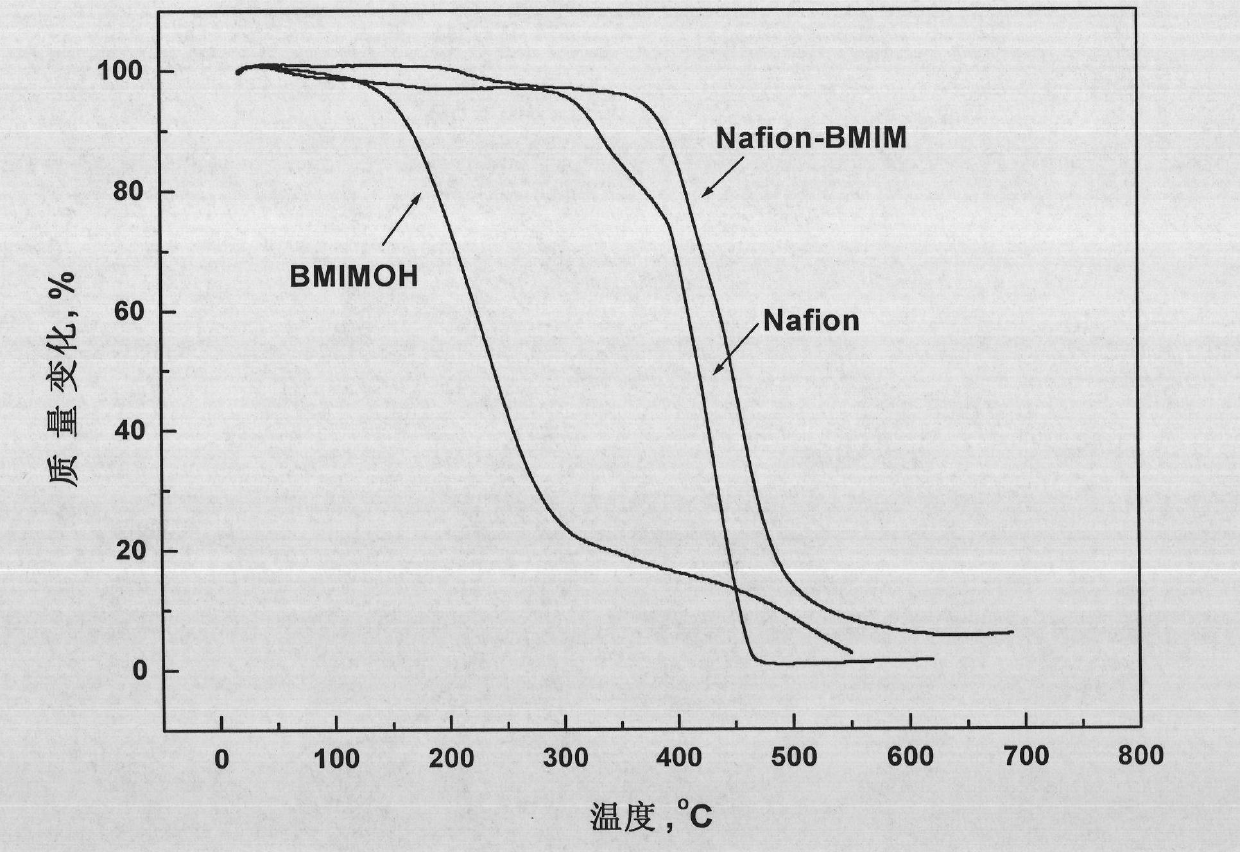

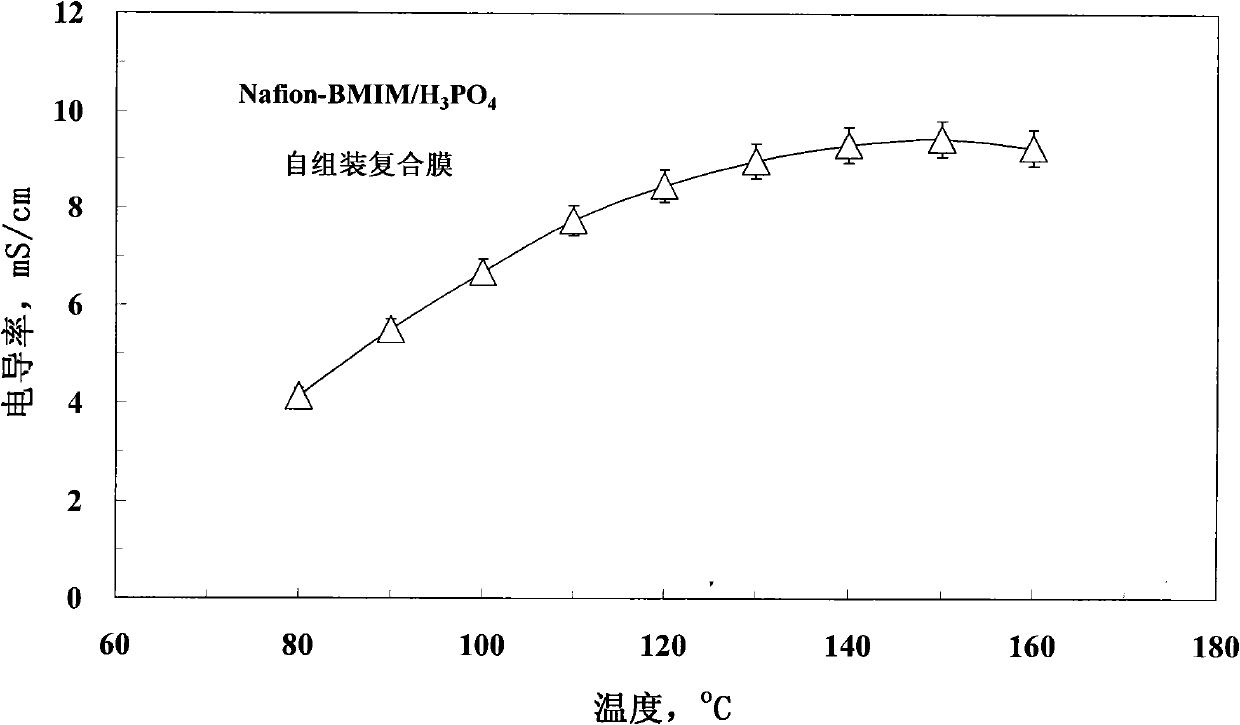

[0035] Preparation of high temperature proton conductor composite membrane (Nafion-BMIM / H 3 PO 4 ) method steps are as follows.

[0036] (1) Pretreatment of Nafion membrane

[0037] The perfluorinated sulfonic acid membrane was sequentially placed in H 2 o 2 In aqueous solution, 80°C deionized water, H 2 SO 4 Soak in the aqueous solution for 1 hour, rinse with deionized water at room temperature, and soak the membrane in deionized water at room temperature for later use.

[0038] The perfluorinated sulfonic acid membrane adopts Nafion membrane. h 2 o 2 The volume concentration of the aqueous solution is 6%, and the temperature is 80°C; H 2 SO 4 The concentration of the aqueous solution is 0.6mol / L, and the temperature is 80°C.

[0039] (2) Put the pretreated Nafion membrane into an oven, dry it at 110°C for 7 hours, put the ionic liquid into the container, completely soak the Nafion membrane with constant weight after drying in the BMIMOH ionic liquid, and seal the ...

Embodiment 2

[0043] Preparation of high temperature proton conductor composite membrane (Nafion-BMIM / H 3 PO 4 ) method steps are as follows.

[0044] (1) Pretreatment of Nafion membrane

[0045] The perfluorinated sulfonic acid membrane was sequentially placed in H 2 o 2 In aqueous solution, 70°C deionized water, H 2 SO 4 Soak in the aqueous solution for 2 hours each, and then rinse with deionized water at room temperature, then soak the membrane in deionized water at room temperature for later use.

[0046] The perfluorinated sulfonic acid membrane adopts Nafion membrane. h 2 o 2 The volume concentration of the aqueous solution is 3%, and the temperature is 70°C; H 2 SO 4 The concentration of the aqueous solution is 0.3mol / L, and the temperature is 70°C.

[0047] (2) Put the pretreated Nafion membrane into an oven, dry it at 120°C for 6 hours, put the ionic liquid into the container, completely soak the Nafion membrane with constant weight after drying in the BMIMOH ionic liqui...

Embodiment 3

[0051] Preparation of high temperature proton conductor composite membrane (Nafion-BMIM / H 3 PO 4 ) method steps are as follows.

[0052] (1) Pretreatment of Nafion membrane

[0053] The perfluorinated sulfonic acid membrane was sequentially placed in H 2 o 2 In aqueous solution, 90°C deionized water, H 2 SO 4 Soak in the aqueous solution for 0.5h each, and then rinse with deionized water at room temperature, then soak the membrane in deionized water at room temperature for later use.

[0054] The perfluorinated sulfonic acid membrane adopts Nafion membrane. h 2 o 2 The volume concentration of the aqueous solution is 8%, and the temperature is 90°C; H 2 SO 4 The concentration of the aqueous solution is 0.8mol / L, and the temperature is 90°C.

[0055] (2) Put the pretreated Nafion membrane into an oven, dry at 100°C for 8 hours, put the ionic liquid into the container, completely soak the Nafion membrane with constant weight after drying in the BMIMOH ionic liquid, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com