Method for preparing N-isopropyl acrylamide/multi-walled carbon nanotube composite microgel through in situ polymerization in microreactor

A technology of isopropylacrylamide and multi-walled carbon nanotubes, which is applied in the field of preparation of PNIPAM microgels, can solve the problems that the properties of polymer gels are difficult to meet, and achieve short reaction time, uniform particle size, and simple preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

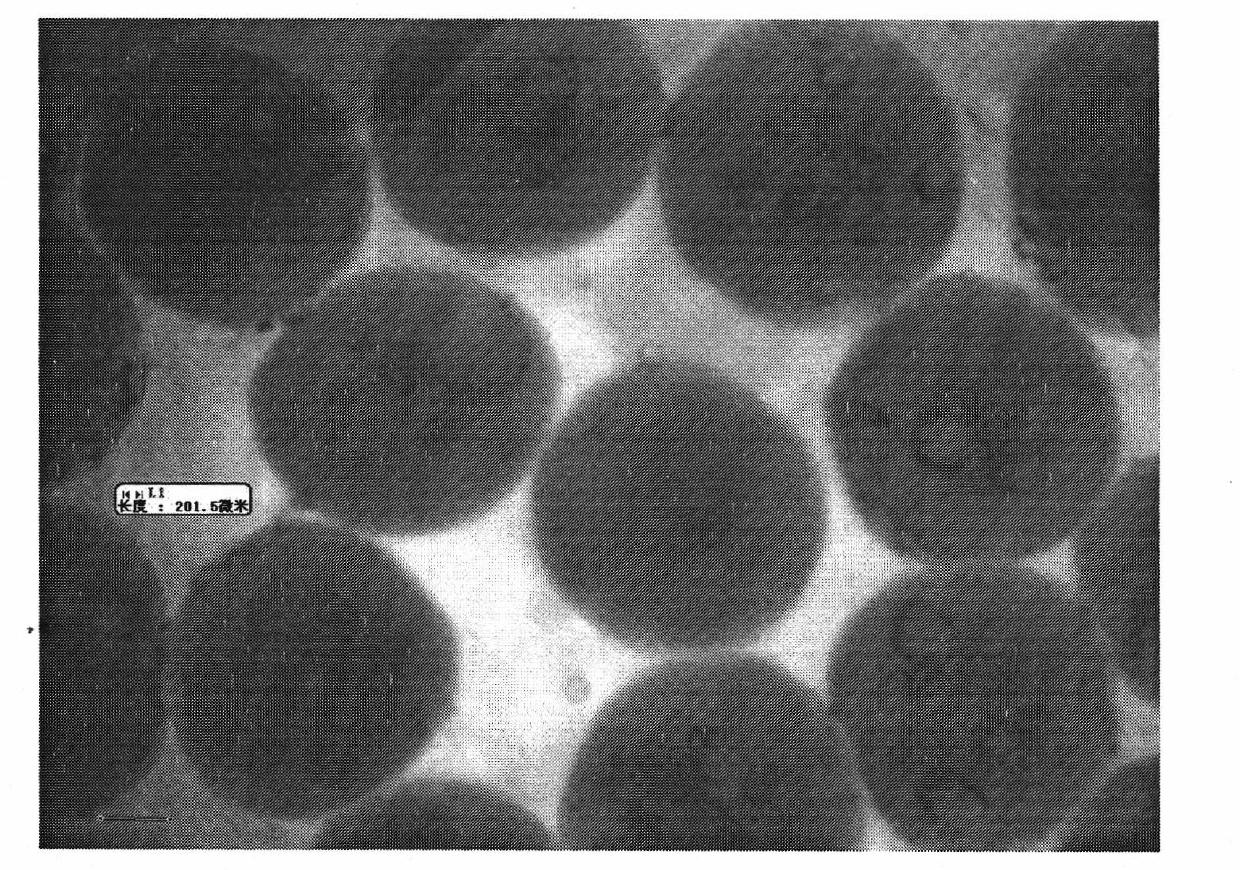

Embodiment 1

[0030] (1) Adding multi-walled carbon nanotubes in the nitric acid aqueous solution whose ratio of nitric acid and water is 2:1, the ratio of multi-walled carbon nanotubes and nitric acid solution is 0.003g / ml, under the condition of 100 ℃ of oil bath, react 24 hour, the pH value of the washing adjustment solution is 7, and drying obtains the modified multi-walled carbon nanotube with good dispersibility in water;

[0031] (2) 0.1093g of N-isopropylacrylamide (monomer), 0.070g of N, N'-methylenebisacrylamide (crosslinking agent), 0.0906g of ammonium peroxosulfate (initiator) , 0.010g of the above-mentioned modified multi-walled carbon nanotubes were mixed with 10ml of distilled water to obtain a dispersed phase solution; 5ml of N,N,N',N'-tetramethylethylenediamine was poured into a beaker containing 50mL of soybean oil, Stir gently with a glass rod to make it evenly mixed to obtain a continuous phase solution with a concentration of 10% (v / v);

[0032] (3) Put the two solutio...

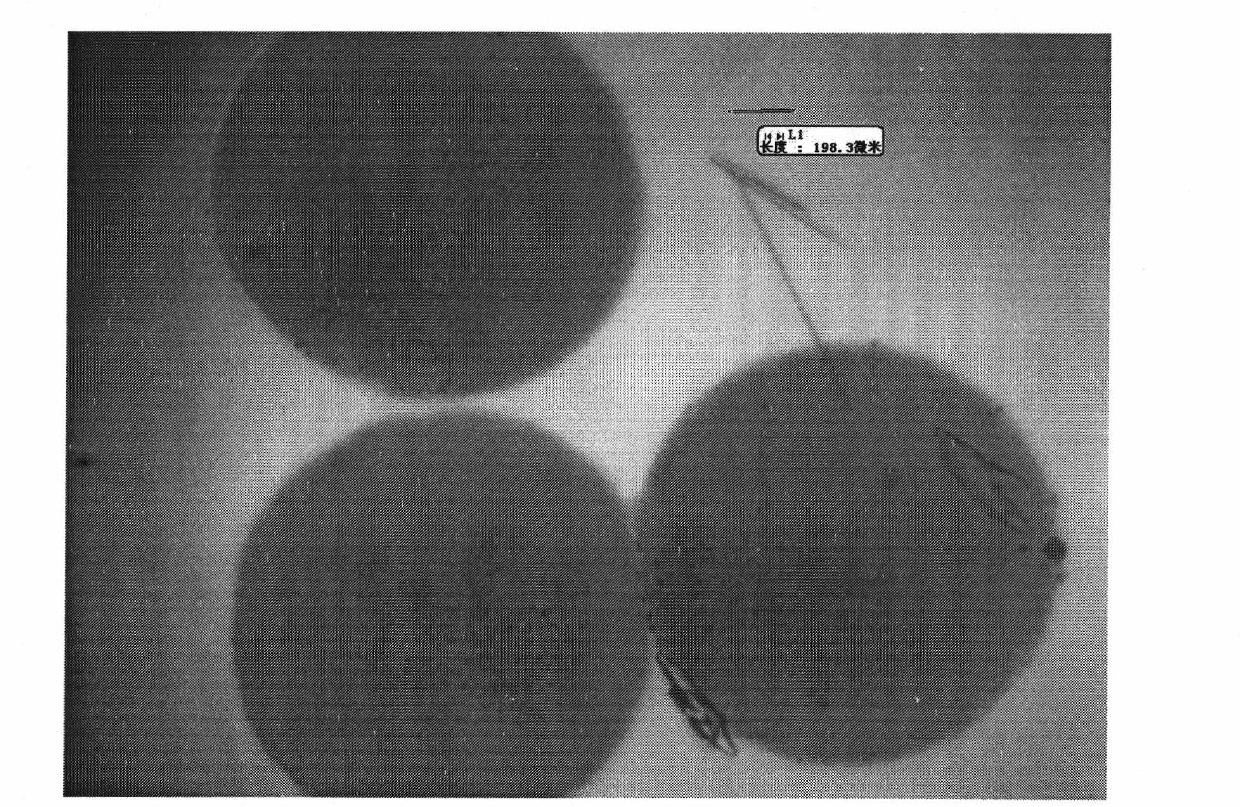

Embodiment 2

[0034] (1) Add multi-walled carbon nanotubes in the nitric acid aqueous solution whose ratio of nitric acid and water is 2:1, the ratio of multi-walled carbon nanotubes and nitric acid solution is 0.003g / ml, under the condition of 100 ℃ of oil bath, react 36 hour, the pH value of the washing adjustment solution is 7, and drying obtains the modified multi-walled carbon nanotube with good dispersibility in water;

[0035] (2) 0.153g of N-isopropylacrylamide (monomer), 0.09g of N, N'-methylenebisacrylamide (crosslinking agent), 0.0706g of ammonium peroxosulfate (initiator) , 0.009g of the above-mentioned modified multi-walled carbon nanotubes were mixed to obtain a dispersed phase solution, and 5ml of N,N,N',N'-tetramethylethylenediamine was poured into a beaker containing 50mL of soybean oil, and gently mixed with a glass rod Stir to make it evenly mixed to obtain a continuous phase solution;

[0036](3) Put the two solutions into 10mL glass syringes respectively, place them on...

Embodiment 3

[0038] (1) Adding multi-walled carbon nanotubes in the nitric acid aqueous solution whose ratio of nitric acid and water is 2:1, the ratio of multi-walled carbon nanotubes and nitric acid solution is 0.003g / ml, under the condition of 100 ℃ of oil bath, react 24 hour, the pH value of the washing adjustment solution is 7, and drying obtains the modified multi-walled carbon nanotube with good dispersibility in water;

[0039] (2) 0.2011g of N-isopropylacrylamide (monomer), 0.08g of N, N'-methylenebisacrylamide (crosslinking agent), 0.0806g of ammonium peroxosulfate (initiator) , 0.008g of the above-mentioned modified multi-walled carbon nanotubes and 10ml of distilled water were mixed to obtain a dispersed phase solution, and 15ml of N, N, N', N'-tetramethylethylenediamine was poured into a beaker containing 50mL soybean oil, and the glass Gently stir the stick to mix well to obtain a continuous phase solution;

[0040] (3) Put the two solutions into 10mL glass syringes respecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com