Polycarboxylic acid water reducing agent and preparation method thereof

A technology of polycarboxylic acid and water-reducing agent, applied in the field of concrete water-reducing agent, can solve the problems of complicated addition and metering of admixtures, difficult operation control, deterioration of concrete workability, etc., so as to shorten synthesis time, prevent erosion, and protect from The effect of erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A kind of polycarboxylate superplasticizer, the weight percent of its each component is made up of:

[0042] Polycarboxylate 40

[0043] Rust inhibitor sodium nitrite 22

[0044] Air-entraining agent sodium dodecylbenzene sulfonate 1.7

[0045] Water repellant sodium stearate 10

[0046] Defoamer polyether polyol 0.3

[0047] Volume stabilizer aluminum sulfate 26

Embodiment 2

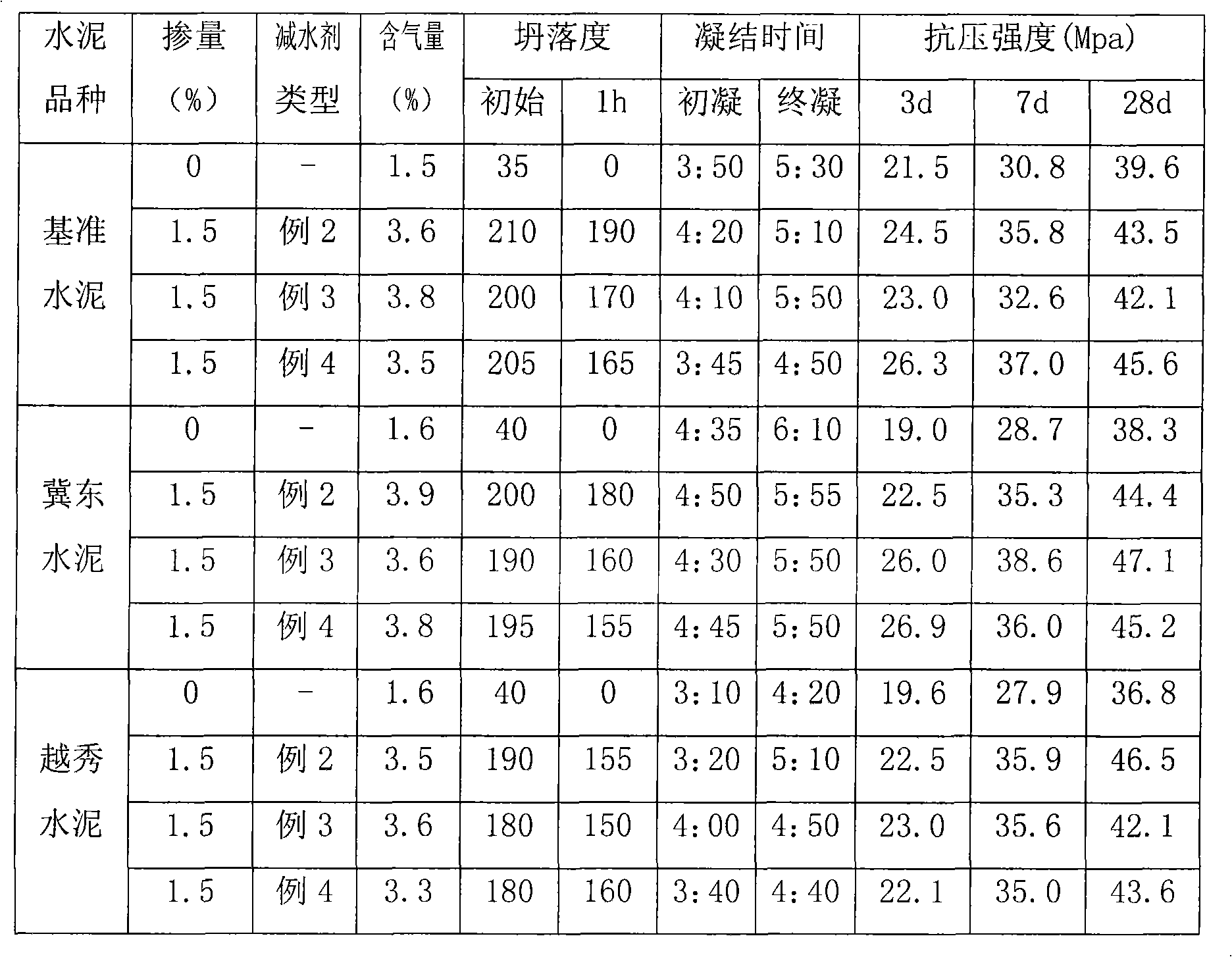

[0049] The preparation method of polycarboxylate superplasticizer: add 180g of polycarboxylate superplasticizer with a solid content of 40% into the reaction vessel equipped with stirring, condensation and filtration devices, heat and stir at 80°C, add rust inhibitor Sodium nitrate 50g, air-entraining agent sodium dodecylbenzene sulfonate 3.2g, waterproofing agent sodium stearate 30g, add water 120g, react for 50 minutes, add defoamer polyether polyol 1.5g, volume stabilizer aluminum sulfate 70g, carry out synthesis reaction. After constant temperature reaction for 1 hour, use a filter to filter the insoluble matter to obtain the finished product 1 with a concentration of 48.9%.

Embodiment 3

[0051] The preparation method of polycarboxylate superplasticizer: add 150g of polycarboxylate superplasticizer with a solid content of 40% into the reaction vessel equipped with stirring, condensation and filtration devices, heat and stir at 60°C, add rust inhibitor Sodium nitrate 70g, air-entraining agent sodium dodecylbenzenesulfonate 2.2g, waterproofing agent sodium stearate 25g, add water 150g, react for 30 minutes, add defoamer polyether polyol 1.2g, volume stabilizer aluminum sulfate 80g, carry out synthesis reaction. After constant temperature reaction for 2 hours, use a filter to filter the insoluble matter to obtain the finished product 2 with a concentration of 47.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com