Technique for directly recycling water and other resources in production process of caffeine

A technology of production process and process technology, applied in the direction of water/sewage treatment, water/sludge/sewage treatment, alkali metal hydroxide, etc., can solve the problems of difficult treatment and high cost, achieve small investment, realize economic benefits, The effect of increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

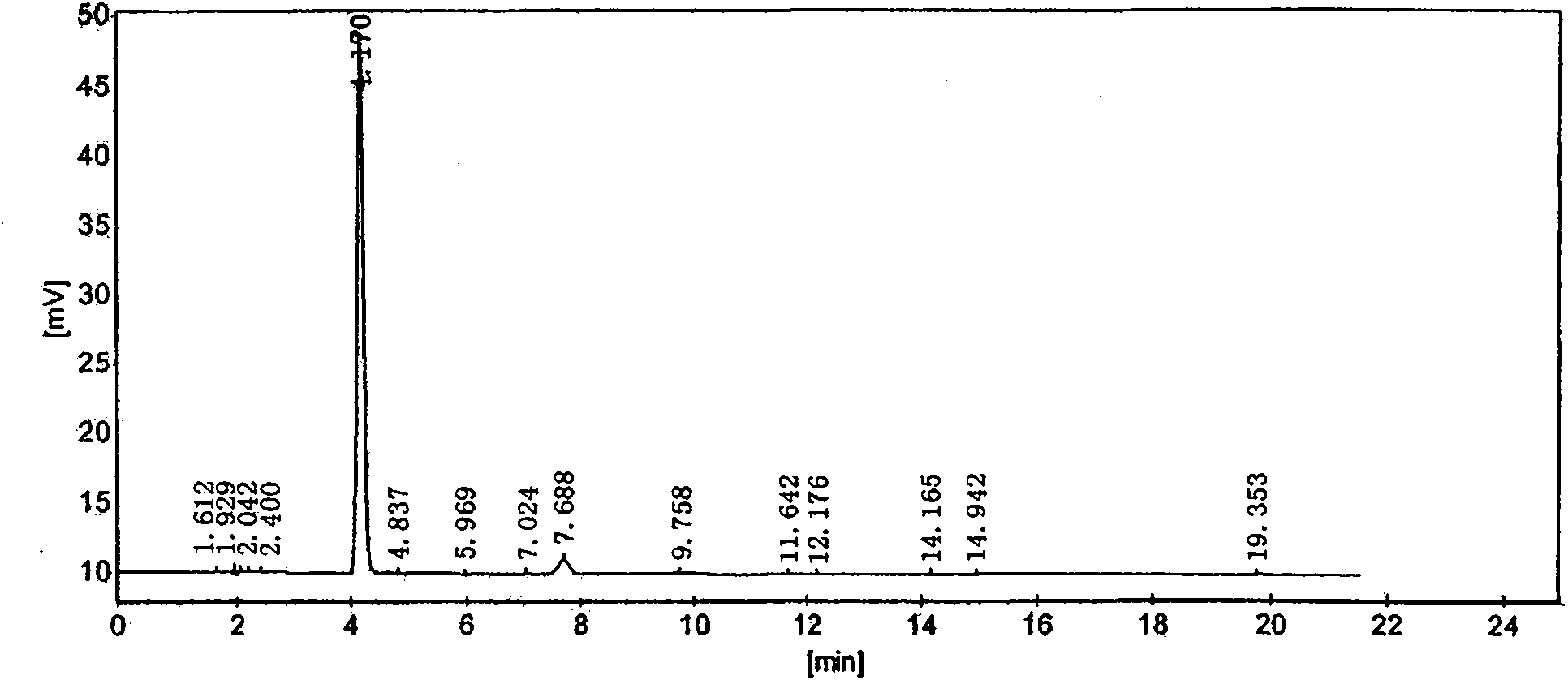

Image

Examples

Embodiment 1

[0019] Take 200ml of the original mother liquor for washing with water, add 7.0204g of quicklime, stir for 1 hour and then filter with suction to obtain the required circulating liquid, wash and dry the precipitate.

[0020] In a water bath less than 70°C, take 50ml of dimethylcyanoacetylurea (PH=2.0~2.5), add 170ml of the above-mentioned filtrate during stirring, and then add PH=8~9, and add 3ml of 10% NaOH, then PH=9.3~9.7 , raise the temperature to 88-90°C, keep warm at this temperature for 30 minutes, retest the pH value every 10 minutes during the heat preservation process, keep the pH value between 9.3-9.7, and cool the material to 48-52°C after the reaction , to realize the cyclization reaction in the caffeine synthesis process.

[0021] At room temperature, take 3.5035g of sodium nitrite and dissolve it in the above cooling solution, slowly add 18ml of 31% H 2 SO 4 After putting it in the three-necked bottle, PH=3.0~3.5, then drop the starch potassium iodide test sol...

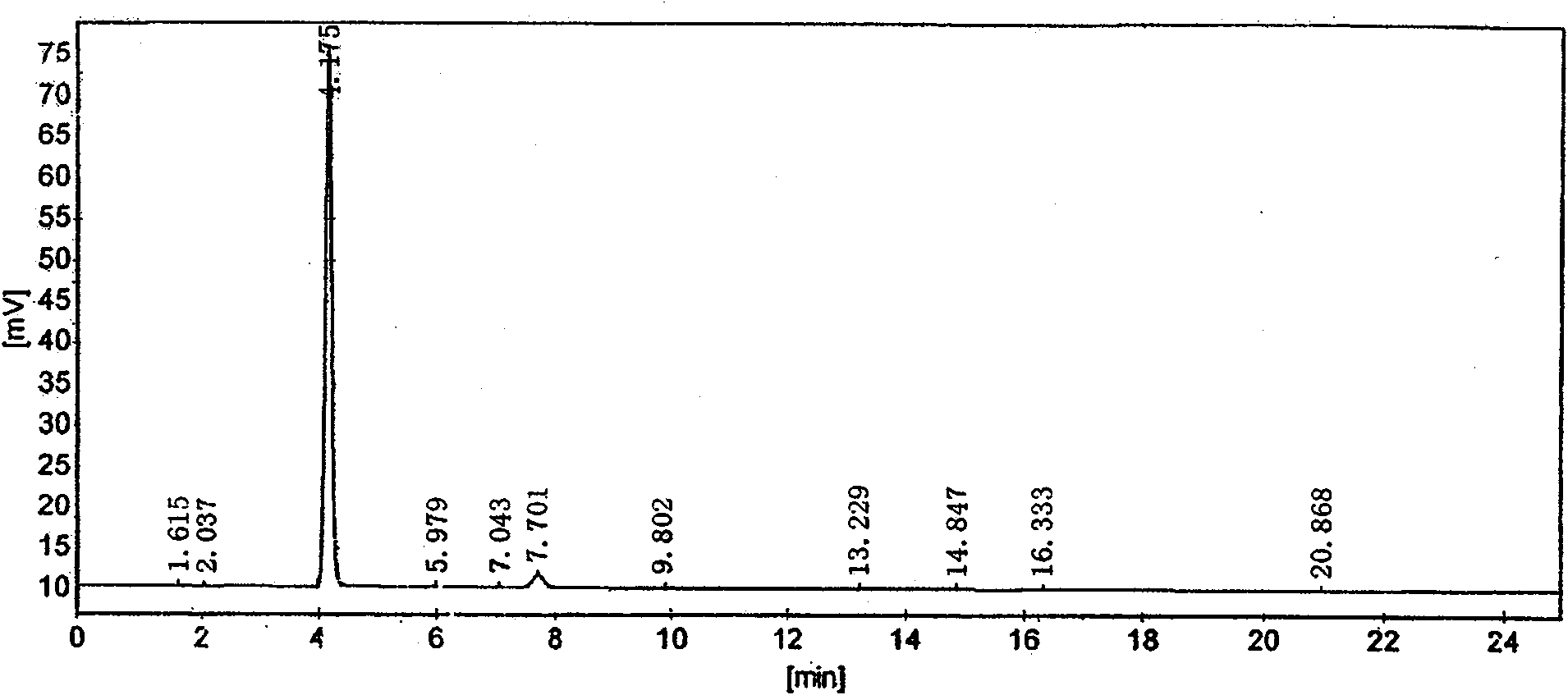

Embodiment 2

[0023] After repeating the reaction of Example 1 for 5 times, take 200ml of the obtained circulating liquid for six times, add 7.0208g of quicklime, stir for 1 hour and then filter with suction to obtain the required circulating liquid, wash and dry the precipitate.

[0024] In a water bath less than 70°C, take 50ml of dimethylcyanoacetylurea (PH=2.0~2.5), add 170ml of the above-mentioned filtrate during stirring, and then add PH=7~8, add 7.5ml of 10% NaOH, and then add PH=9.3~ 9.7, raise the temperature to 88-90°C, keep warm at this temperature for 30 minutes, retest the pH value every 10 minutes during the heat preservation process, keep the pH value between 9.3-9.7, and cool the material to 48-52 after the reaction ℃, to realize the cyclization reaction in the caffeine synthesis process.

[0025] At room temperature, take 3.5096g of sodium nitrite and dissolve in the above cooling solution, slowly add 18ml of 31% H 2 SO 4 After putting it in the three-necked bottle, PH=3....

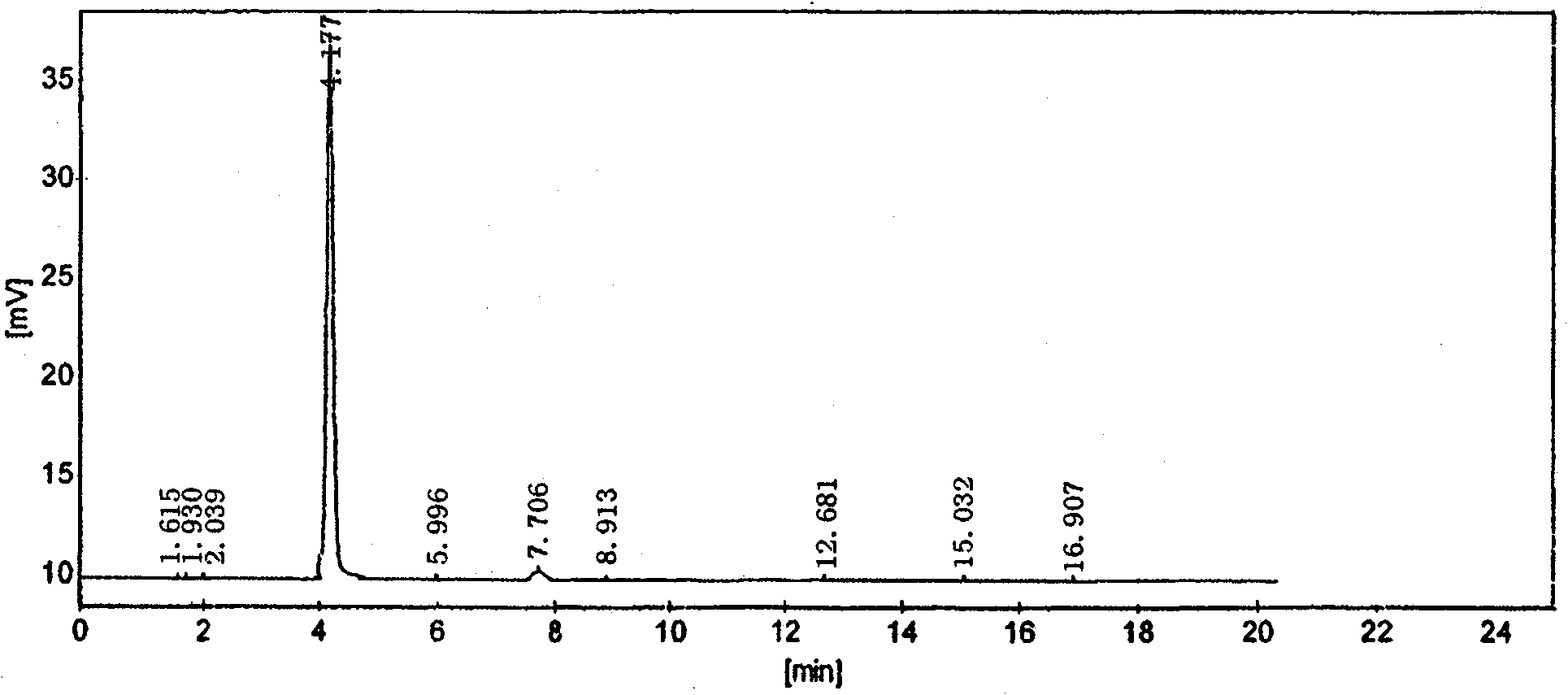

Embodiment 3

[0027] Take 200ml of water to wash the original mother, add 3.5142 quicklime, stir for 1 hour and filter with suction to obtain the required circulating liquid, wash and dry the precipitate.

[0028] In a water bath less than 70°C, take 50ml of dimethylcyanoacetylurea (PH=2.0~2.5), add 170ml of the above-mentioned filtrate during stirring, and then add PH=6~7, and add 10ml of 10% NaOH, then PH=9.3~9.7 , raise the temperature to 88-90°C, keep it warm at this temperature for 30 minutes, retest the pH value every 10 minutes during the heat preservation process, keep the pH value between 9.3-9.7, and cool the material to 48-52°C after the reaction , to realize the cyclization reaction in the caffeine synthesis process.

[0029] At room temperature, take 3.5044g of sodium nitrite and dissolve it in the above cooling solution, slowly add 18ml of 31% H 2 SO 4 After putting it in the three-necked bottle, PH=3.0~3.5, then drop the starch potassium iodide test solution on the color co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com