Method for recycling ink box with differential pressure valve and recycled ink box

A recycling method and technology of differential pressure valve, applied in printing and other directions, can solve the problems of cumbersome recycling methods and easy ink leakage of ink cartridges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

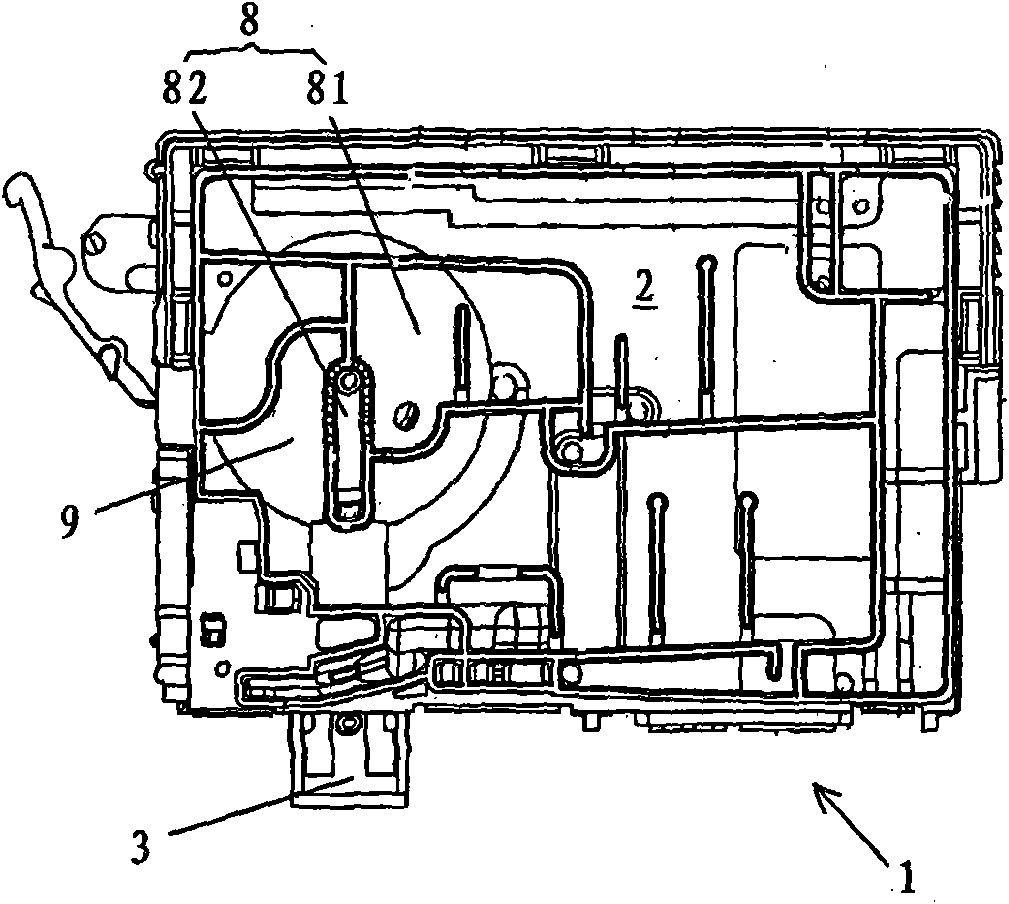

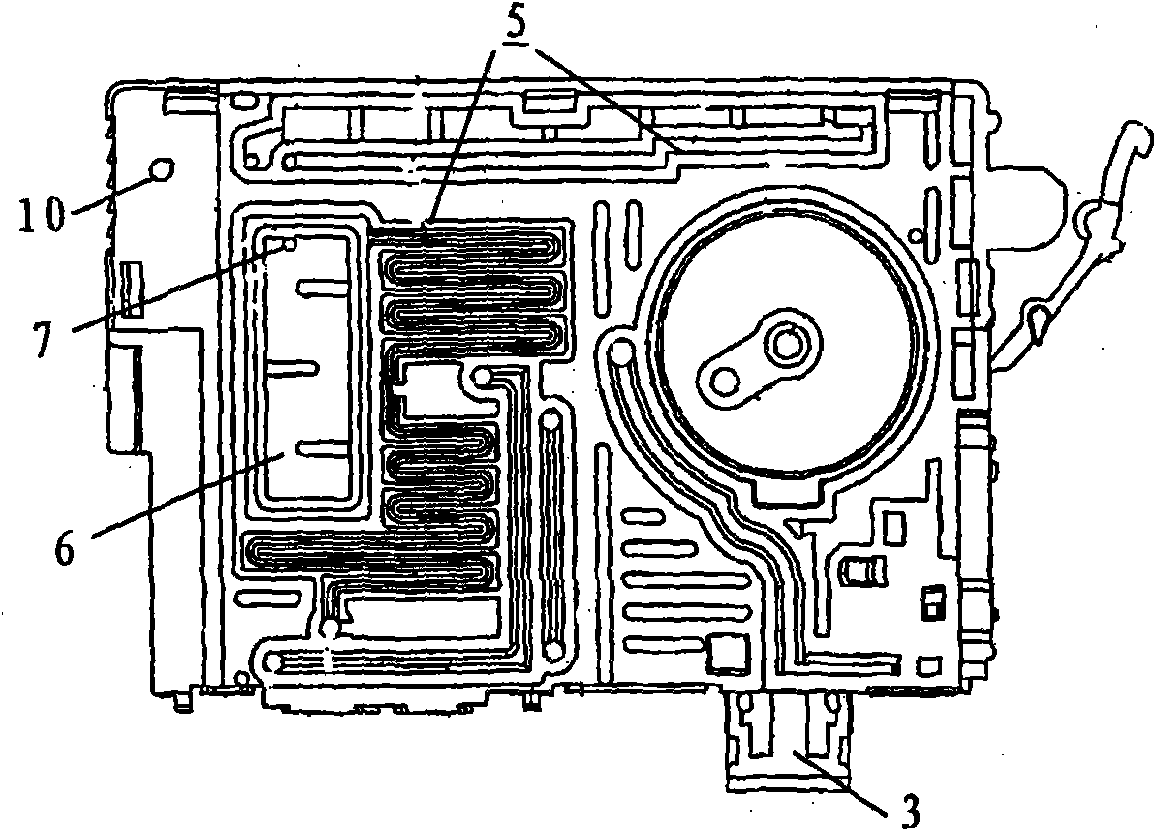

[0022] like Figure 1-3 Shown, a kind of recovery method of inkjet printer ink box, described ink box 1 comprises: ink storage chamber 2, can hold the ink that supplies to inkjet printer printhead; The ink in 2 is supplied to the print head; the valve mechanism 4 is set in the ink supply port 3 and consists of a valve core, a spring and a sealing ring. When the ink cartridge is not installed on the printer, it will Under the action of the elastic force of the spring, the valve mechanism is in a closed state. When the ink cartridge is installed on the printer, the ink supply needle on the printer cooperates with the ink supply port, and at this time the When the insertion force of the ink needle is greater than the elastic force, the valve mechanism is opened; the air communication channel 5 communicates the ink storage chamber with the external atmosphere, and has a gas-liquid separation membrane 6 and a through hole 7 on it, and the gas-liquid Separation membrane 6 is formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com