Method and tool for decementing light machine assembly parts

A technology for dismantling tools and assembling parts, applied in manufacturing tools, hand-held tools, etc., can solve the problems of dimensional deformation, low shear strength, structural damage, etc., and achieve the effect of reducing the risk of adhesive glue and simple and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

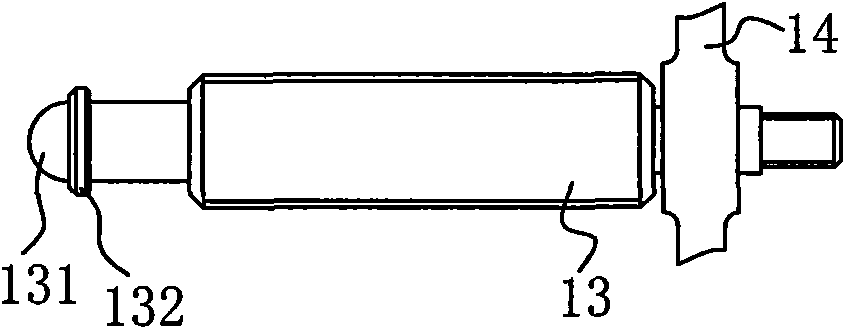

[0031] see figure 1 and figure 2 , the deglue tool of the present invention includes a base plate 3, a fixed assembly and a thrust assembly; the fixed assembly includes a baffle plate 4 fixed on the left side of the base plate 3, and two limit seats 9 arranged on the right side of the base plate 3; the base plate 3 is provided with multiple A row of screw holes, the baffle plate 4 is fixed in the screw holes at different positions to adapt to different sizes of the gluing machine assembly 1 to be dismantled, and the limit seat 9 is provided with a device that can press the gluing machine assembly 1 to be disassembled to the baffle plate 4 adjusting screw 91; the thrust assembly includes a guide frame 11, a bracket 12, a push rod 13, a push rod pressing plate 10, a push claw 8, two push blocks 6, and a wrench 14; a threaded hole 121 is provided in the bracket 12; see Figure 3 to Figure 6 , the circumferential side of the push rod 13 is provided with a screw thread matched wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com