Noise-reduction, oil-removal and impurity-reduction muffler, compressor pump body and compressor equipped with compressor pump body

A muffler and noise reduction technology, applied in the field of compressors, can solve the problems that the muffler can't effectively separate oil and impurities, start up noise, and functional defects, etc., to improve long-term working reliability, reduce start-up noise, and structural design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

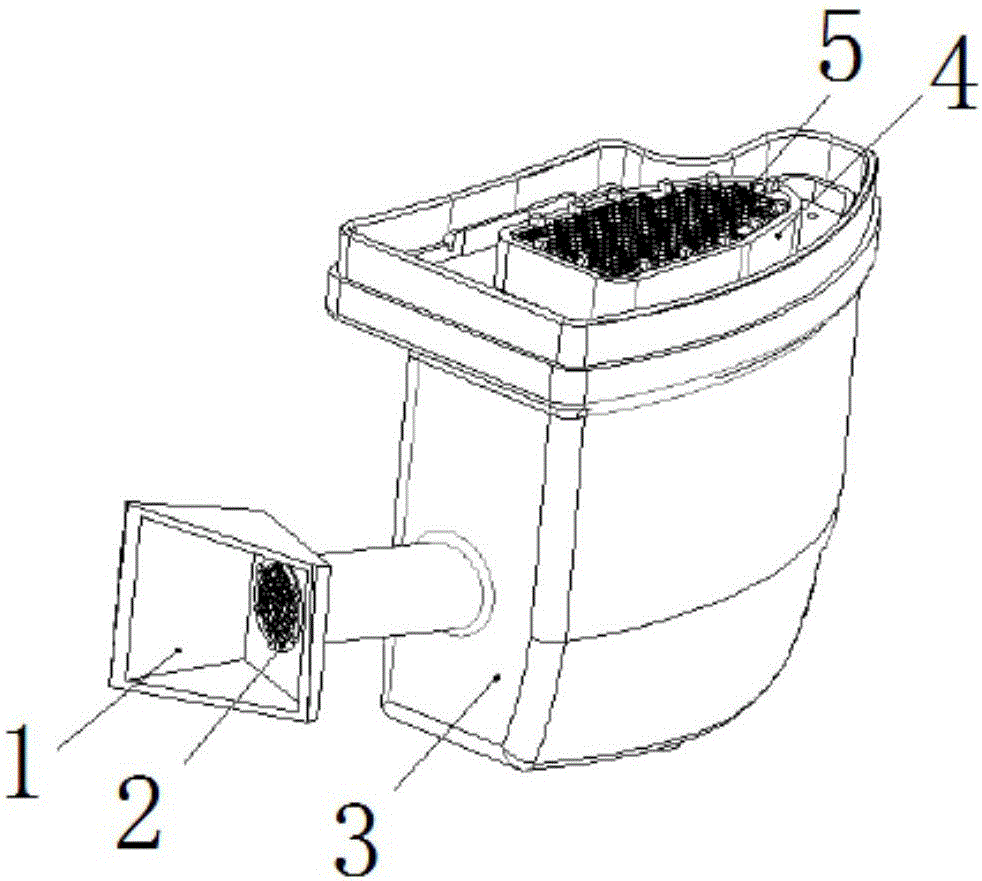

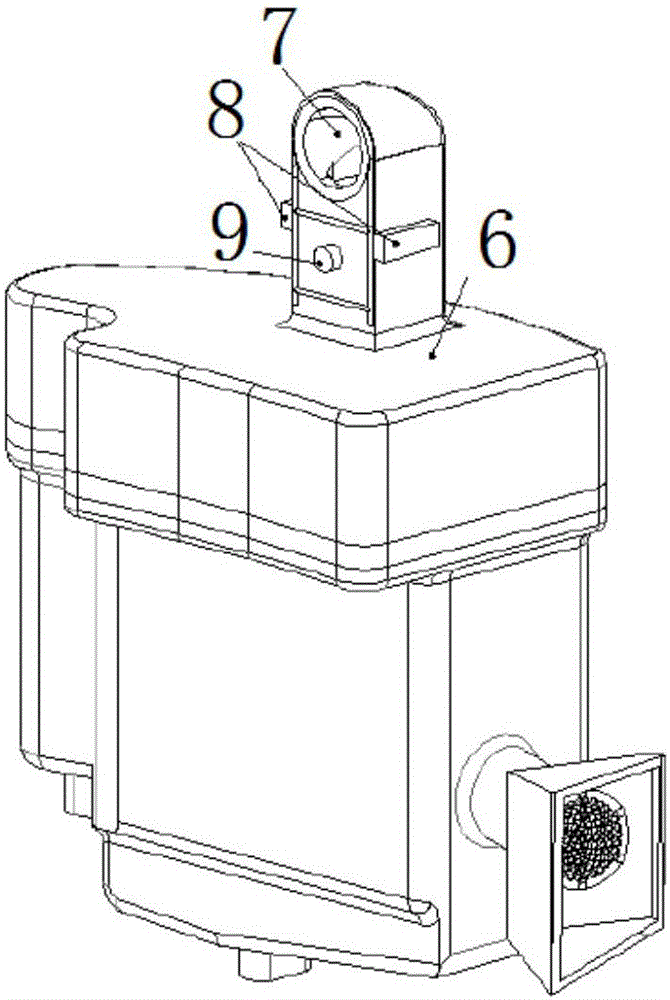

[0041] Example 1, such as Figures 1 to 3 As shown, this kind of suction muffler with steel wire perforated plate includes the suction port 1 of the pump body suction sounder of the refrigeration compressor, the perforated plate 2 at the suction port at the suction port, the lower anechoic chamber 3 and the lower anechoic chamber Connector 4 on the upper chamber, the perforated plate 5 of the communicator can be welded on the upper part of the connector 4 as required, the upper anechoic chamber 6 connects the communicator 4 and the lower anechoic chamber 3 closely together by ultrasonic or hot-melt welding, and the upper anechoic chamber The chamber 6 cooperates with the positioning groove of the cylinder head 14 through the supporting positioning ear 8, and the upper anechoic chamber is provided with a refrigerant outlet 7, and at the same time, the upper positioning pin 9 on the upper anechoic chamber 6 cooperates with the positioning hole in the valve plate 12 to ensure that...

Embodiment 2

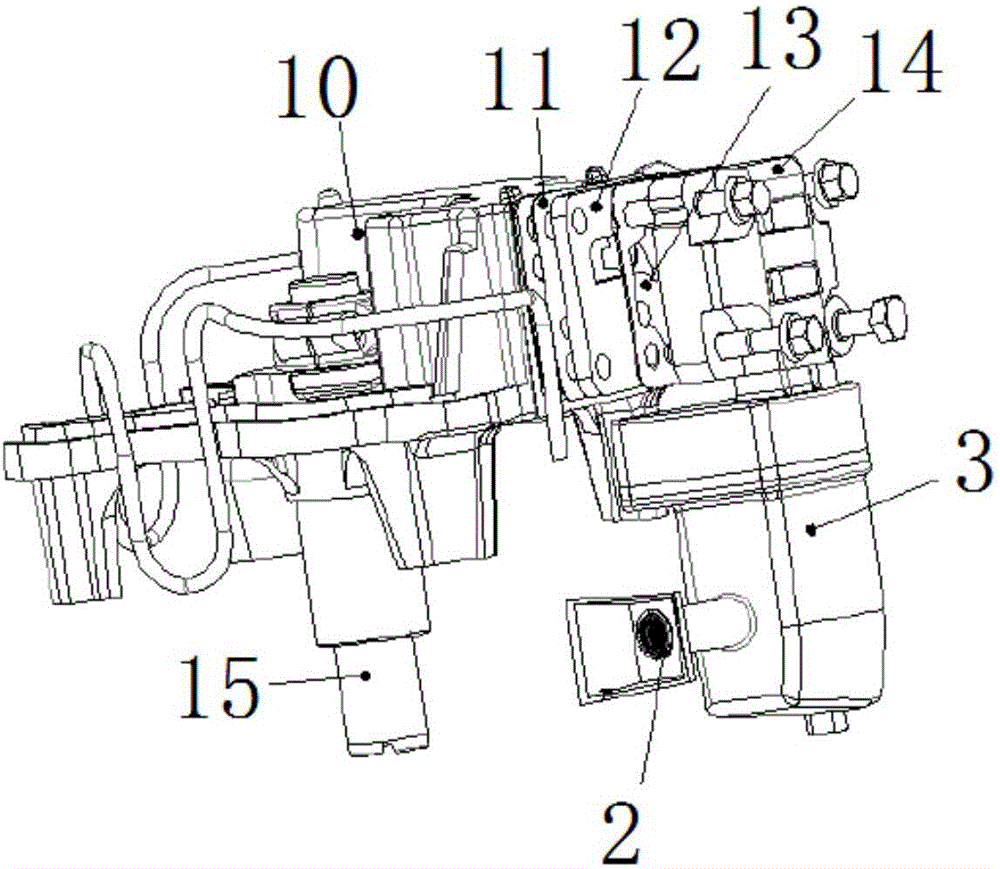

[0043] Example 2, such as Figure 4 to Figure 7 As shown, the pump body with a resonator muffler includes a suction port perforated plate 16 with a resonant cavity muffler, a lower anechoic chamber 17 with a resonant cavity muffler, and an upper anechoic chamber on a cylinder head 18 equipped with a resonant cavity muffler. The upper anechoic chamber is composed of an upper anechoic chamber refrigerant inlet 21 and an upper anechoic chamber refrigerant outlet channel 20 .

[0044] Inhaled low-temperature and low-pressure refrigerant enters the lower anechoic chamber 17 with a resonant chamber muffler through the suction port perforated plate 16 with a resonant chamber muffler, and reaches the lower anechoic chamber 17 with a resonant chamber muffler. After that, part of the refrigerant passes through the upper anechoic chamber for cooling. The agent inlet 21 enters the resonance chamber on the left side of the lower anechoic chamber 17, the right side is the main anechoic cham...

Embodiment 3

[0045] Example 3, such as Figures 1 to 3 with Figure 8 as well as Figure 9 As shown, in order to achieve a better effect of noise reduction, impurity removal and oil reduction, on the basis of Embodiment 1, the refrigerant reaches the lower anechoic chamber 3 and passes through the communicator perforated plate 5 above the communicator 4, and the communicator perforated plate 5 and the upper The anechoic chamber also plays the role of orifice plate noise reduction. The amount of noise reduction can be adjusted to the aperture on the perforated plate 5 of the communicator. It is preferable that the aperture can be adjusted to 0.4-1.0 mm, and the perforation rate of the perforated plate of the communicator is 1% to 18%. ;At the same time, because the flow rate of the refrigerant is relatively fast, and the movement of the compressor is reciprocating, so there is a pulsation phenomenon when the gas enters, because the high-speed pulsating gas will be accompanied by a large no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com