Forming method of bending wave steel webs and special module

A technology of corrugated steel webs and forming methods, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of poor quality of finished products, low production efficiency of corrugated steel webs, small power configuration of presses, etc., and achieve saving Energy, production accuracy, easy control, and small power configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

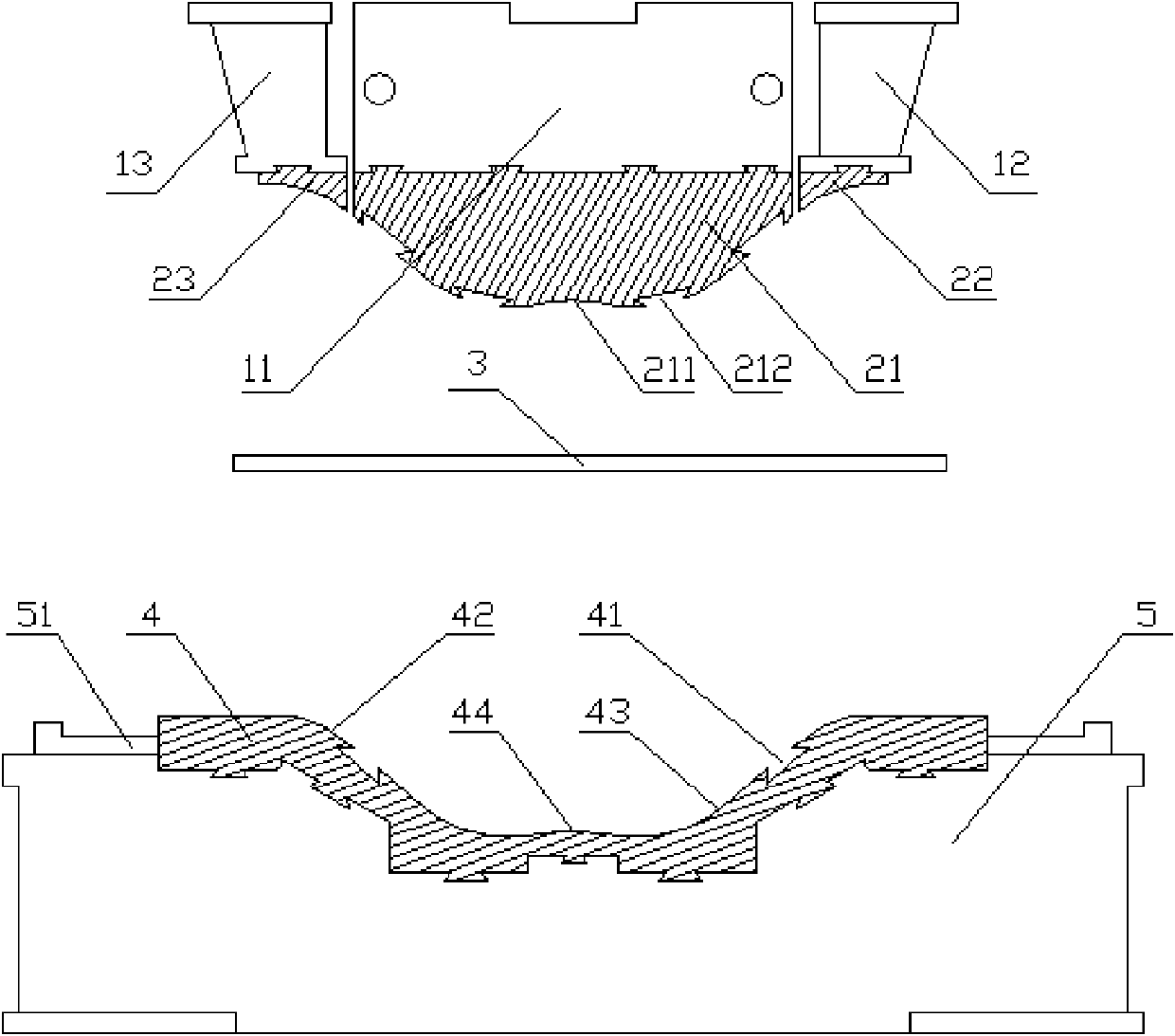

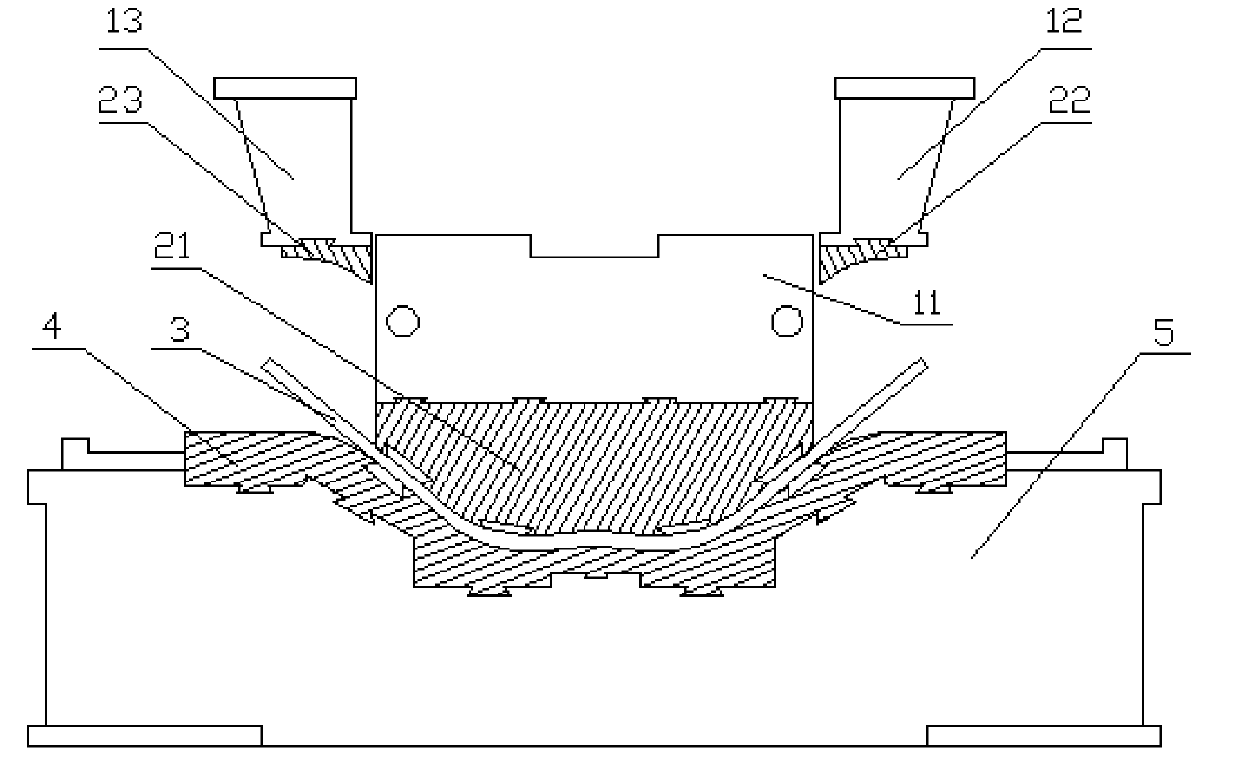

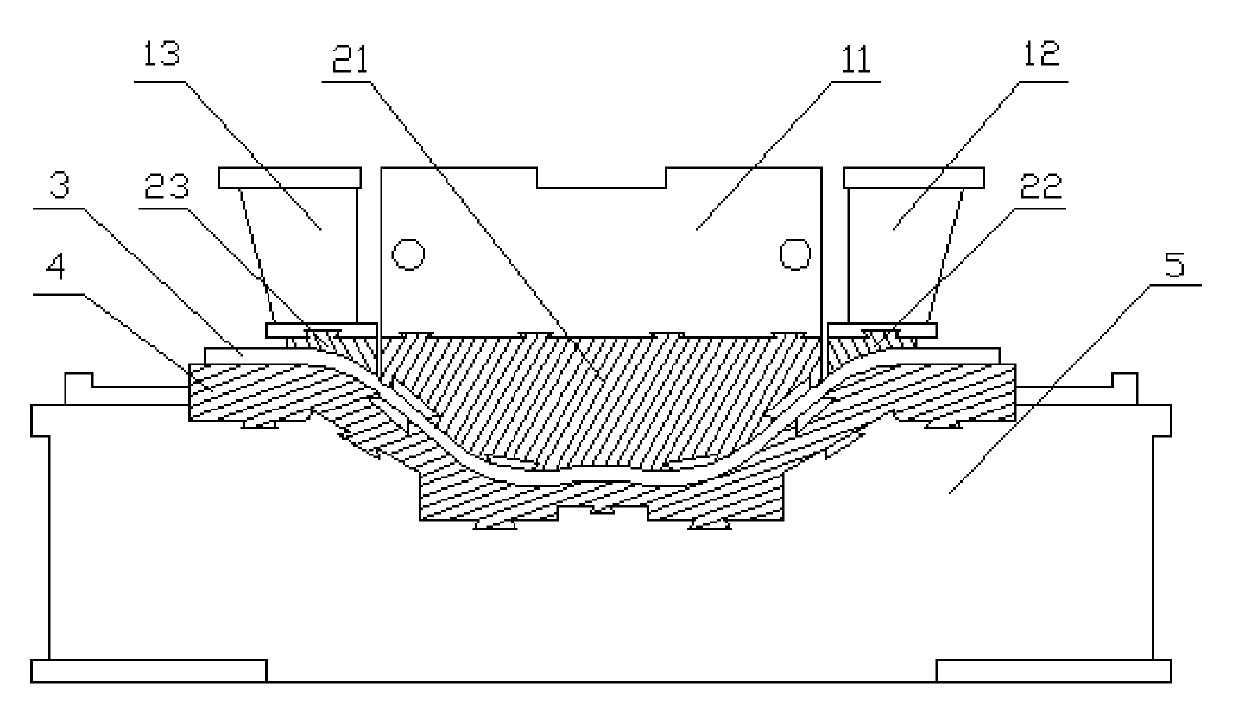

[0031] Bending corrugated steel web forming method and special mold, such as Figure 1 to Figure 3 As shown, the bending type corrugated steel web forming method comprises the following steps:

[0032] a. Put the steel plate 3 that has been cut after turning over the sample into the mold according to the inflection point of the corner;

[0033] b. The middle press 11 is loaded, and the middle press 11 pushes the middle pressure head 21 to bend the steel plate 3 for the first time;

[0034] c. At the same time, the piezoresistor on the middle pressure head 21 and the lower mold 4 monitors the stress on the steel plate 3. When the force on the steel plate 3 is within the set range, that is, when the steel plate 3 is formed into a specified shape, the pressure The sensitive resistor transmits the data to the control center, and the control center controls the stopping of the loading of the press 11 and starts holding the pressure;

[0035] d. The control center controls the pre...

Embodiment 2

[0047] Bending corrugated steel web forming method and special mold, such as Figure 1 to Figure 3 As shown, the bending type corrugated steel web forming method comprises the following steps:

[0048] a. Put the steel plate 3 that has been cut after turning over the sample into the mold according to the inflection point of the corner;

[0049] b. The middle press 11 is loaded, and the middle press 11 pushes the middle pressure head 21 to bend the steel plate 3 for the first time;

[0050] c. At the same time, the piezoresistor on the middle pressure head 21 and the lower mold 4 monitors the stress on the steel plate 3. When the force on the steel plate 3 is within the set range, that is, when the steel plate 3 is formed into a specified shape, the pressure The sensitive resistor transmits the data to the control center, and the control center controls the stopping of the loading of the press 11 and starts holding the pressure;

[0051] d. The control center controls the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com