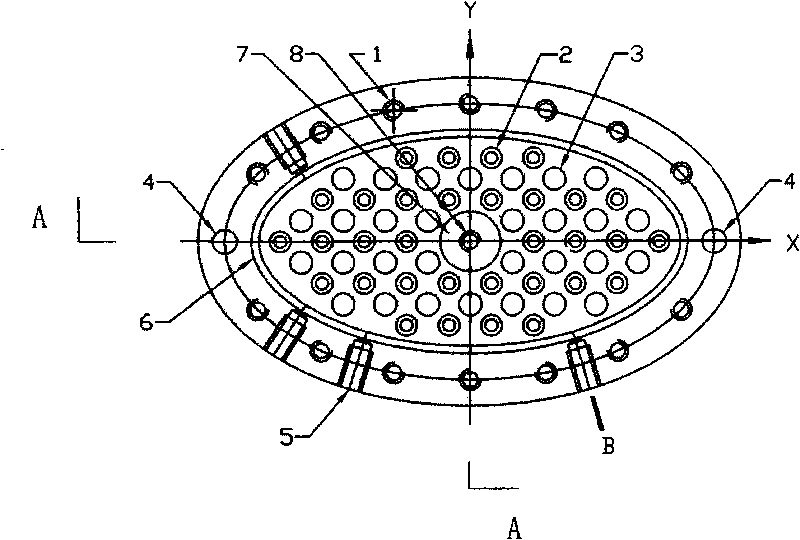

Sound head polar plate of elliptical microphone

An elliptical and polar plate technology, applied in the field of microphone capsules, can solve the problems of complex production, poor reliability, and high cost, and achieve the effects of simple production, flat frequency response, and wide frequency response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

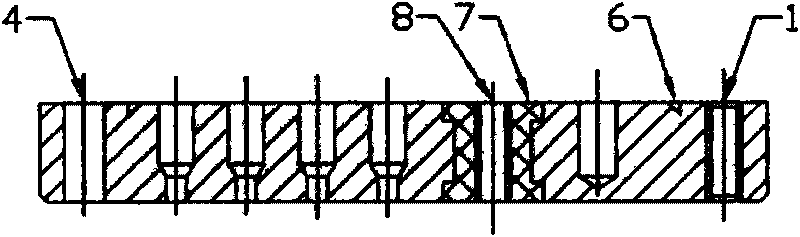

[0018] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

[0019] Concrete processing steps of the present invention are as follows:

[0020] 1. Select the silicon bronze rod, according to the thickness of the car (the allowance for grinding), and drill the center hole Φ4-0.2.

[0021] 2. Wire-cut ellipse (it is best to use medium-feeding or slow-feeding wire to form), leaving a polishing allowance.

[0022] 3. The engraving machine processes elliptical grooves and scribing ellipses for scribing and drilling.

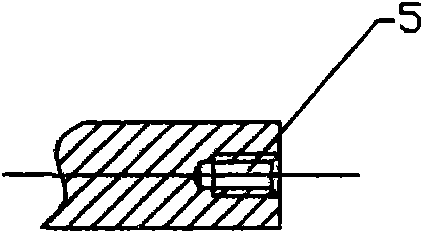

[0023] 4. After the straight calibration knife is calibrated, the PC bar car and the size interference fit are pressed into the hole.

[0024] 5. Flat grinding Coarse and fine grinding two planes, keep parallel wave 0.02mm.

[0025] 6. Drilling, tapping, chamfering and drilling and tapping on the outer circle according to the drawing.

[0026] 7. Deburring and grinding two planes (manual grinding wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com