Method for measuring volatility phenol compound in white wine

A phenolic compound, volatile technology, applied in the field of liquor flavor research, can solve problems such as lack of analytical methods, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

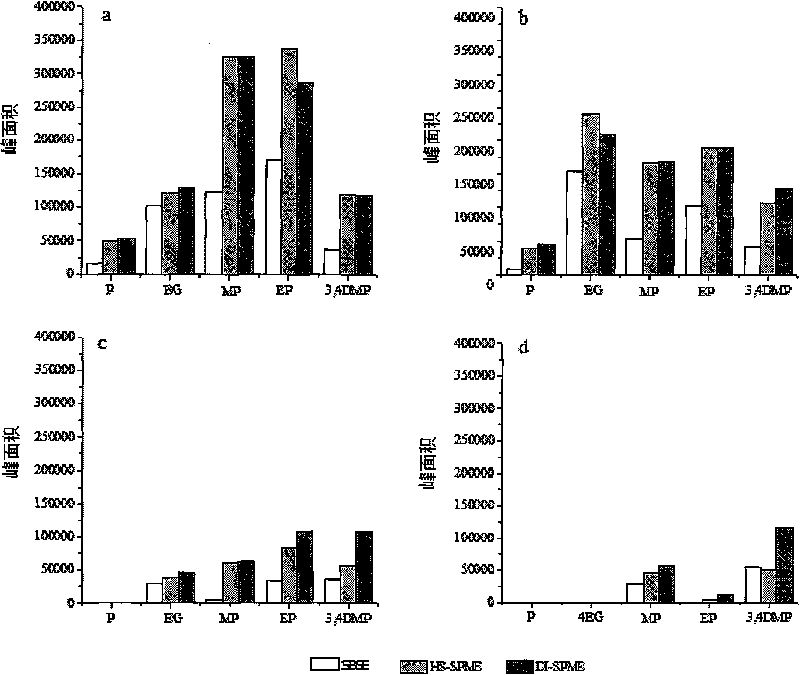

[0033] Embodiment 1: the quantitative method comparison of different extraction modes:

[0034] Select Luzhou-flavor liquor 1 (a), Luzhou-flavor liquor 2 (b), other-flavor liquor (c) and Maotai-flavor liquor (d) for stirring bar adsorption technology (SBSE), headspace Quantitative comparison of three different extraction methods of solid-phase microextraction (HS-SPME) and immersion solid-phase microextraction (DI-SPME), in which DVB / CAR / PDMS was selected as the extraction head for solid-phase microextraction.

[0035] Using the optimized extraction conditions to extract the above four liquors, SPME, whether it is headspace (HS) or immersion (DI) extraction method, is much better than SBSE for the extraction of volatile phenolic compounds in liquor. Relatively speaking, the extraction method of immersion (DI) is better, and its extraction effect on the internal standard compound (3,4DMP) is more stable, see figure 1 .

Embodiment 2

[0036] Example 2: Evaluation of the method:

[0037]With 3,4-dimethylphenol as the internal standard, the linear correlation coefficient R2 of the seven volatile phenolic compounds ranged from 0.9922 (4-methylguaiacol) to 0.9998 (4-methylphenol) The linearity of the obtained standard curve is good, see figure 2 . At the same time, the linear range of the standard curve includes the concentration range of phenolic compounds in liquor. The detection limits of seven phenolic compounds were all less than 7 μg / L, and the detection limit of 4-propylguaiacol was 59.75 ng / L. The overall accuracy of the method is good, and the relative standard deviation is within 15%, which can meet the analysis requirements.

[0038] The present invention has done the mensuration of recovery rate, and the result shows that the recovery rate of this method is all between 85%-115%, see Table 1.

[0039] Table 1 Calculation of recovery and precision (n=3) of phenolic compounds in each wine sample a...

Embodiment 3

[0042] Embodiment 3: the mensuration of actual wine sample:

[0043] The present invention selects Luzhou-flavor liquor, mixed-flavor liquor, sauce-flavor liquor, other fragrance liquor and Fen-flavor liquor as target wine samples, dilutes the five liquors to 5-20% (v / v), and adds 10 μg As an internal standard, the content of phenolic compounds was determined according to the above-mentioned method. Table 2 has listed the content of phenolic compound in the measured wine sample, image 3 It is the GC-MS total ion current chromatogram of other flavor liquor samples.

[0044] Table 2 Contents of various volatile phenolic compounds in different liquors

[0045]

[0046] N.D.: not detected; T.r.: concentration below the lower limit of the standard curve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com