Multi-channel wick-embedded flat plate heat pipe

A technology of flat heat pipes and liquid-absorbing cores, applied in indirect heat exchangers, lighting and heating equipment, etc., which can solve the problem of circuit board burnout, reduction in the performance of electronic components, temperature uniformity and heat transfer capacity indicators that cannot meet the requirements and other problems to achieve efficient work, eliminate local hot spots, and increase the effective heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Carry out further detailed description below in conjunction with accompanying drawing:

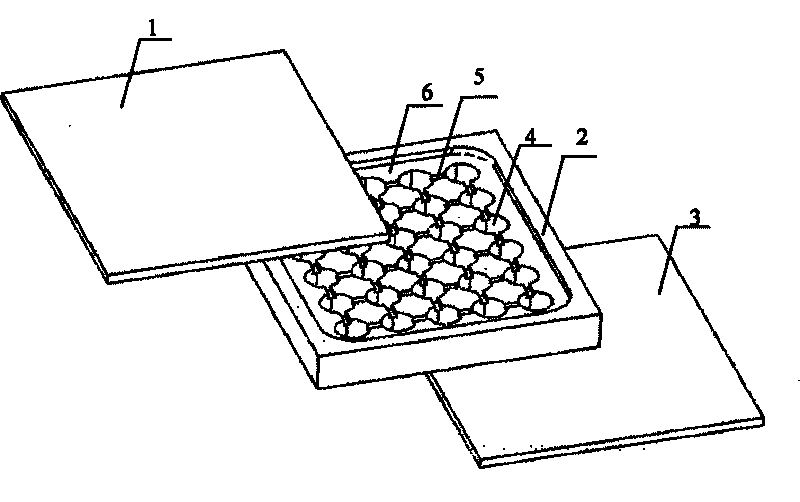

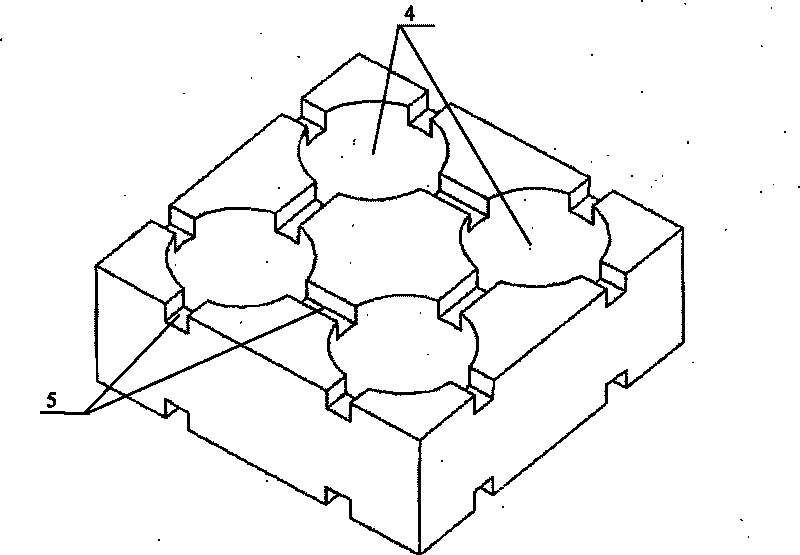

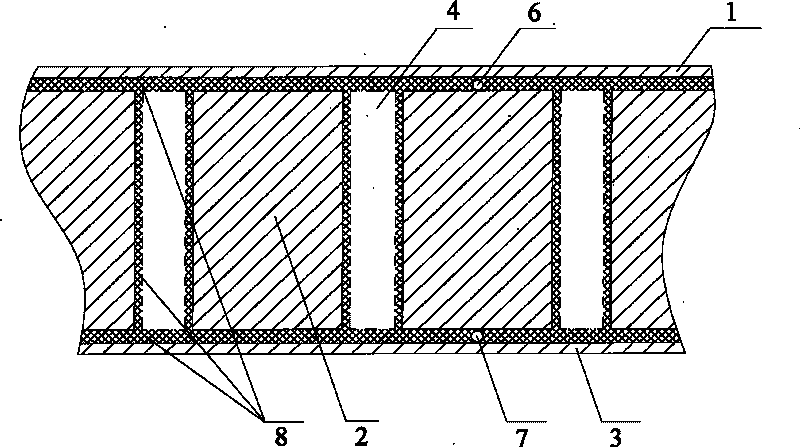

[0031] figure 1A three-dimensional view of the flat heat pipe is given, which is a multi-channel embedded liquid-absorbing core type flat heat pipe, which is composed of a high thermal conductivity substrate, a liquid-absorbing core and a working medium. The substrate can be processed in a split type, that is, it is composed of an upper cover plate 1 , a lower cover plate 3 and an intermediate plate 2 located between the upper cover plate 1 and the lower cover plate 3 . An upper narrow cavity 6 is arranged inside the upper surface of the substrate, and a lower narrow cavity 7 is arranged inside the lower surface of the substrate. The upper narrow cavity 6 is set on the upper surface of the middle plate 3 or the lower surface of the upper cover plate 1 , and the lower narrow cavity 7 can be set on the lower surface of the middle plate 2 or the upper surface of the lower cover plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com