High-speed distributor and application thereof

A technology of distributor and high temperature container, which is used in furnaces, lighting and heating equipment, furnace components, etc., can solve the problems of many heated bearings on the gimbal, unsuitable for high-temperature hot material, and the central feeding pipe is subject to large forces. , to achieve the effect of saving construction costs and maintenance costs, compact structure and convenient cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described:

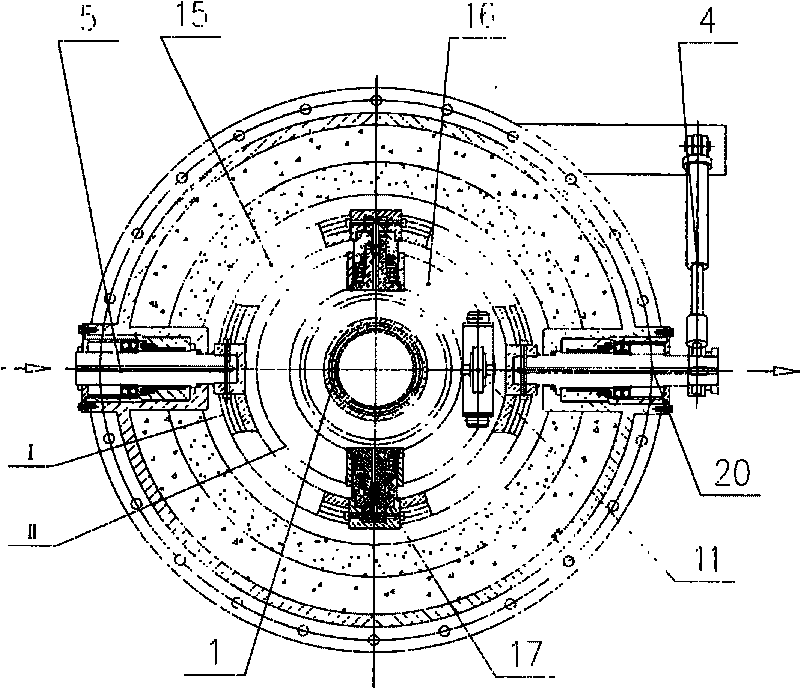

[0026] Such as Figure 1 to Figure 3 As shown, the high-temperature distributor is used for distributing materials in the high-temperature container 10 according to instructions after passing the material through the water-cooled central charging pipe 1 and the hopper nozzle 9 .

[0027] The upper flange of section A of the distributor shell is connected to the flange of the top charging equipment, the lower flange of section C of the distributor shell is connected to the top flange of the high-temperature vessel 10, and each section of shell A, shell B, and shell C is attached with refractory materials.

[0028] The supporting trunnion 5 and the supporting long trunnion 20 are respectively welded on the main ring beam 15 of the distributor, and the supporting trunnion 5 and the supporting long trunnion 20 are supported between the two sections B an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com