Vertical shaft maglev wind power generator

A wind turbine and magnetic levitation technology, which is applied to wind turbines, wind turbine combinations, wind turbines at right angles to the wind direction, etc., can solve the problems of mechanical contact and mechanical friction of fans, which are not completely eliminated, and it is difficult to obtain effective wind energy utilization. Lifting, greatly reducing the starting wind speed of the fan, etc., to achieve the effect of long service life, increasing the number of working hours, and reducing the starting wind speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

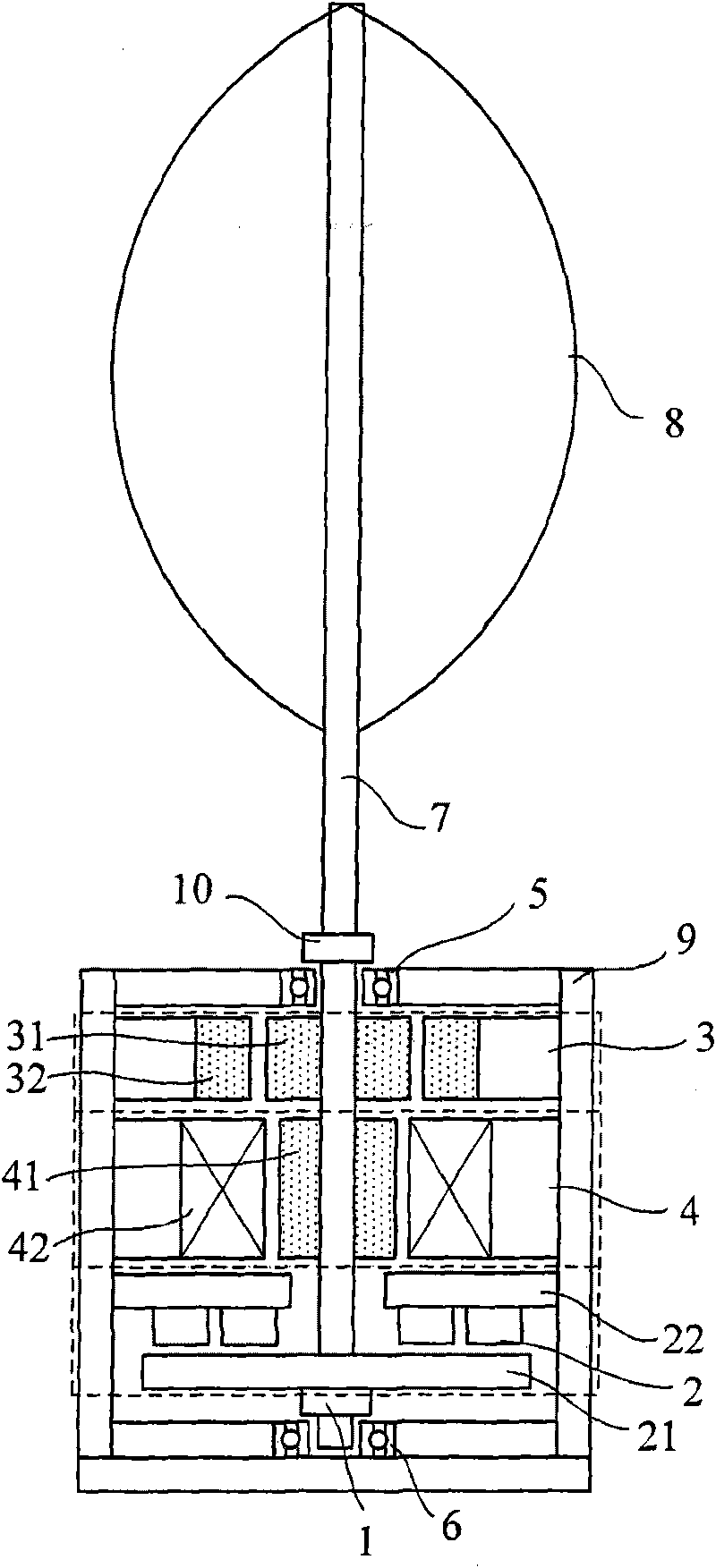

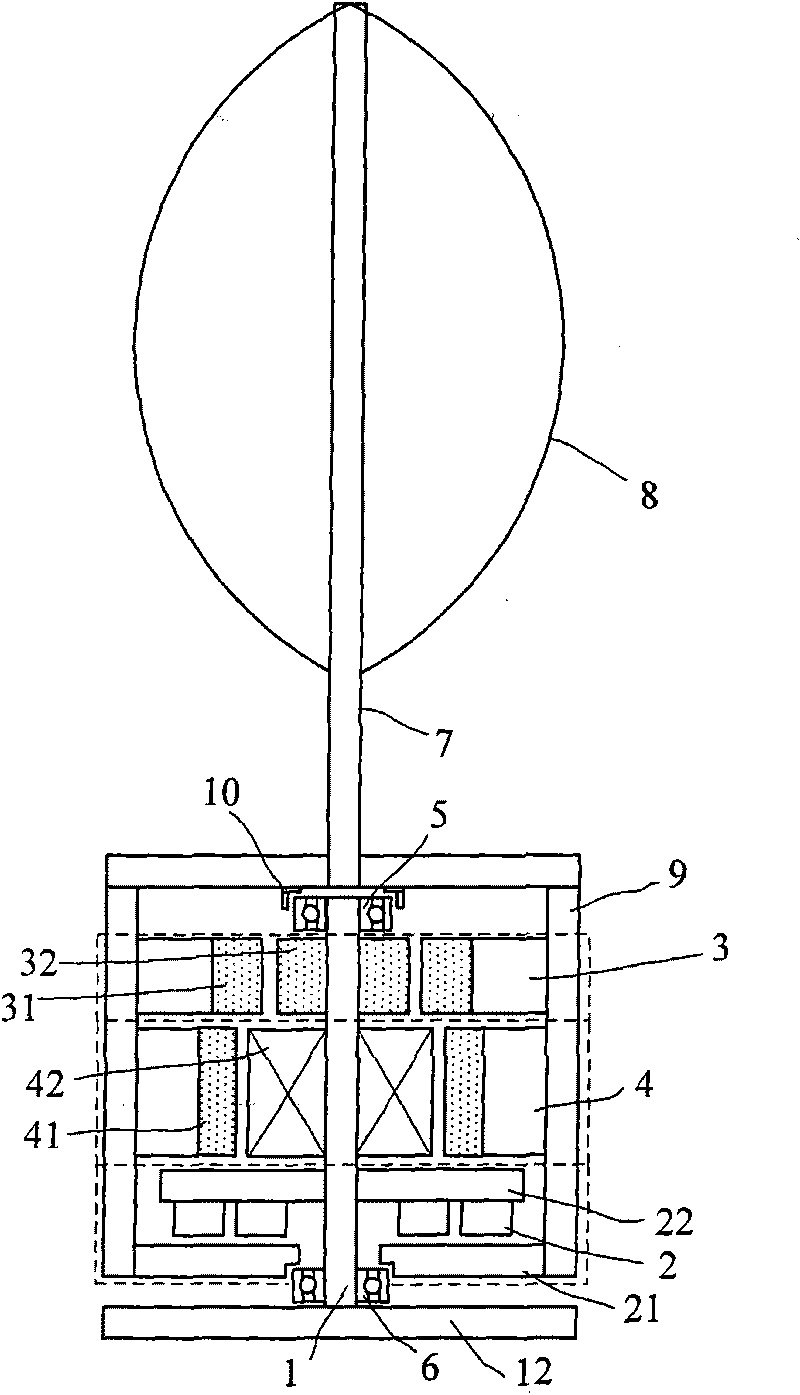

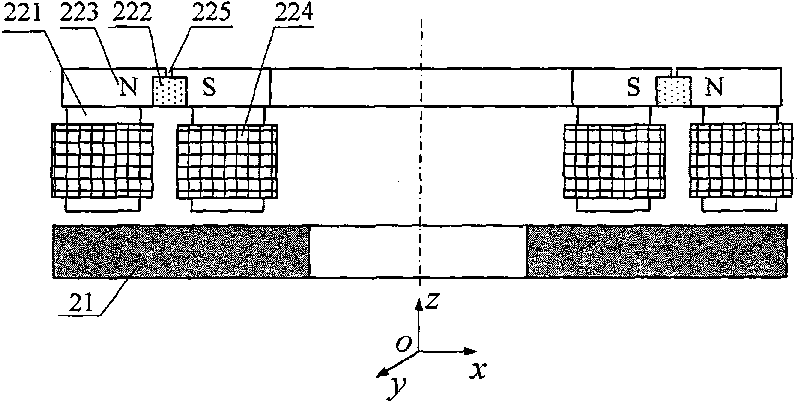

[0026] Such as figure 1 Shown is a vertical shaft inner rotor magnetic levitation wind power generator, which is composed of a rotating part and a stationary part. It is characterized in that: the rotating part includes: blade 8, rotating shaft 7, radial magnetic bearing rotor 31, generator rotor 41, shaft Magnetic bearing suction plate 21, upper protective bearing 5, lower protective bearing 6, upper protective bearing baffle ring 10, lower protective bearing baffle ring 1; the stationary part includes: fan housing 9, radial magnetic bearing stator 32, generator stator 42 , Axial magnetic bearing stator 22; the rotating parts of the fan are all installed on the fan shaft 7, and the fan blade 8, the upper protective bearing baffle ring 10, the radial magnetic bearing rotor 31, the generator rotor 41. Axial magnetic bearing suction disk 21 and lower protective bearing baffle ring 1; between upper protective bearing baffle ring 10 and radial magnetic bearing 3 is the upper end co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com