Prestress carbon fiber sheet reinforcing ground tackle and construction technology for reinforcing concrete structure thereof

A fiber cloth and prestressing technology is applied in the field of prestressed fiber cloth reinforcing anchors and the construction technology of reinforcing concrete structures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

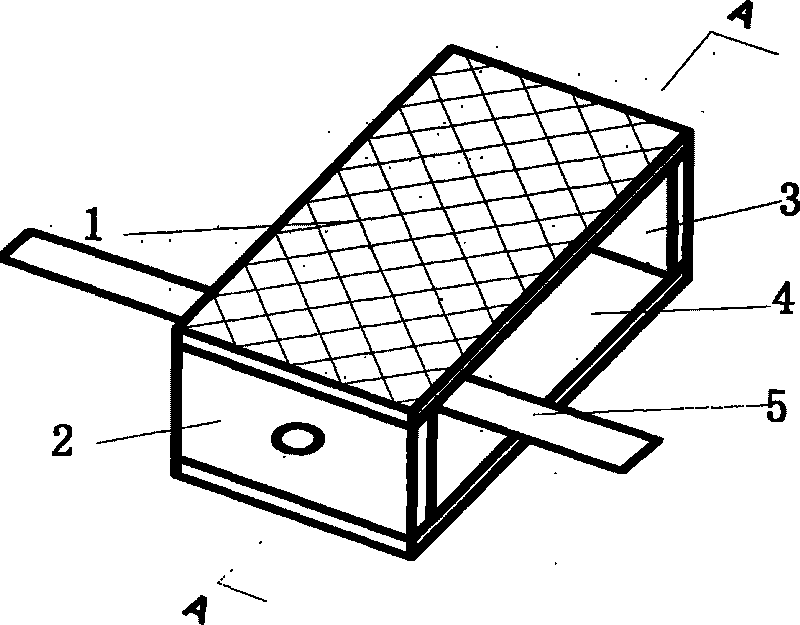

[0028] Attached below figure 1 ~ attached Figure 6 The preparation method of the present invention is further described in detail:

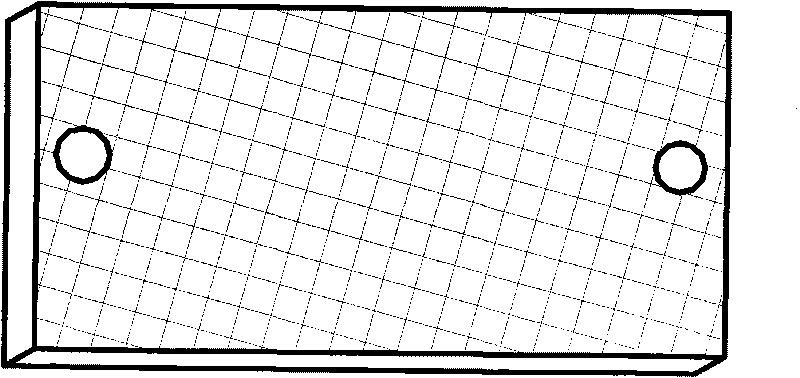

[0029] The tension end anchor 7 includes: a steel plate with grooves 1, the two ends of the steel plate with grooves 1 are vertically welded to one side of the first steel plate with holes 2 and the second steel plate with holes 3, and the steel plate 4 is parallel to the grooved steel plate 4. The grooved steel plate 1 is placed and welded on the other side with the first steel plate with holes 2 and the second steel plate with holes 3; the steel plate with grooves 1, the first steel plate with holes 2, the second steel plate with holes 3, The steel plate 4 forms the side of the cuboid, and the additional bead 5 of the tension end anchor is placed in the side of the cuboid parallel to the grooved steel plate 1 to form the tension end anchor 7 .

[0030] The production method of the steel plate with grooves is the same as that of ZL 2005200076...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com