Rapid low-cost water level lowering well sealing device and construction method thereof

A dewatering well, low-cost technology, applied in infrastructure engineering, construction, etc., can solve the problems of poor sealing effect and long sealing construction period of dewatering wells, achieving good sealing effect, reducing construction costs, and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

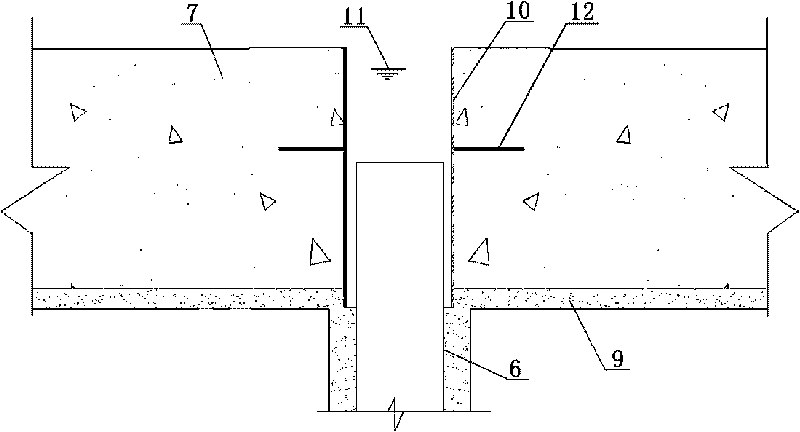

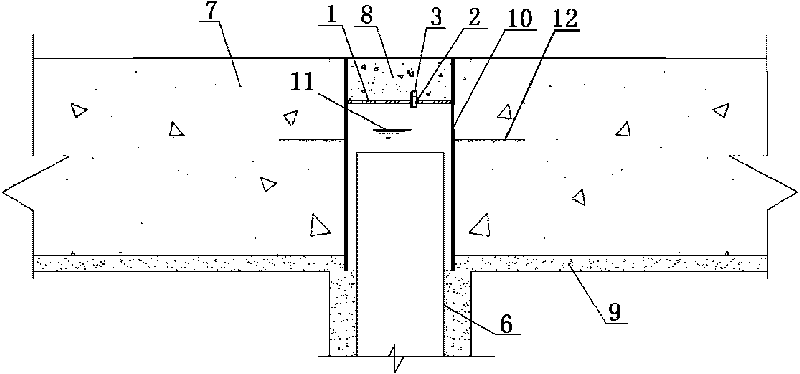

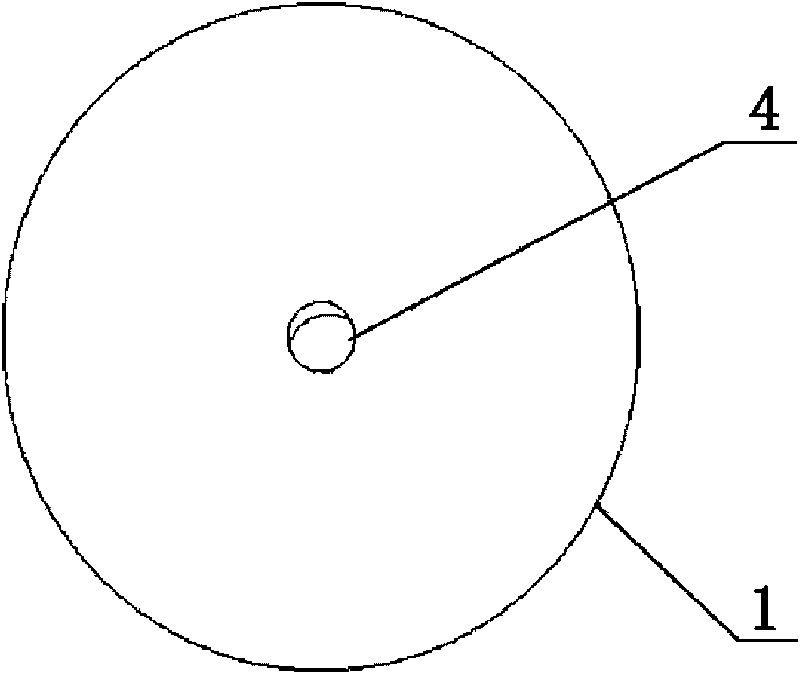

[0035] Embodiment one, see figure 1 , figure 2 As shown, this fast and low-cost closed dewatering well device is located in the upper mouth of the dewatering well 6, and a wellhead pipe 10 is fixed on the upper mouth of the dewatering well 6, and the periphery of the wellhead pipe is welded with a pre-embedded plate 12, and the pre-embedded plate 12 It is an annular plate or a finned plate. The pre-embedded plate is pre-embedded in the floor concrete 7, the wellhead pipe 10 is welded with a head steel plate 1, and there is at least one water gushing hole 4 on the head steel plate, and a sleeve 2 is welded on the water gushing hole, and the sleeve 2 and the plug 3 are threaded connect.

[0036] see Figure 3-Figure 5 As shown, the sleeve 2 has an internal thread, the plug 3 has an external thread, and the top of the plug is connected with a tightening nut 5 . Have a gushing hole 4 on the head steel plate.

Embodiment 2

[0037] Embodiment two, see Figure 6-Figure 8 As shown, the difference from the first embodiment is that the sleeve 2 has external threads, the plug 3 is in the shape of a screw cap with internal threads, and the top of the plug is connected with a tightening nut 5 . Have three gushing holes 4 on the head steel plate.

[0038] Construction method of the present invention sees figure 1 , figure 2 Shown:

[0039] Step 1, a wellhead pipe is fixed on the upper mouth of the dewatering well, and the periphery of the wellhead pipe is welded with a pre-embedded plate 12, and the pre-embedded plate is pre-embedded in the floor concrete 7, and the upper mouth of the wellhead pipe is flush with the floor concrete 7;

[0040] Step 2, weld the head steel plate 1 in the wellhead pipe, weld the periphery of the head steel plate to the inner wall of the wellhead pipe, the distance between the head steel plate and the upper opening of the wellhead pipe is greater than 100mm, and at least o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com