Compulsory pouring device and construction method of bored pile underwater concrete

A technology of underwater concrete and cast-in-place piles, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of material labor, machinery, waste of construction period, troublesome construction, blocked conduits, etc., to save materials and speed up pouring , The effect of reducing material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

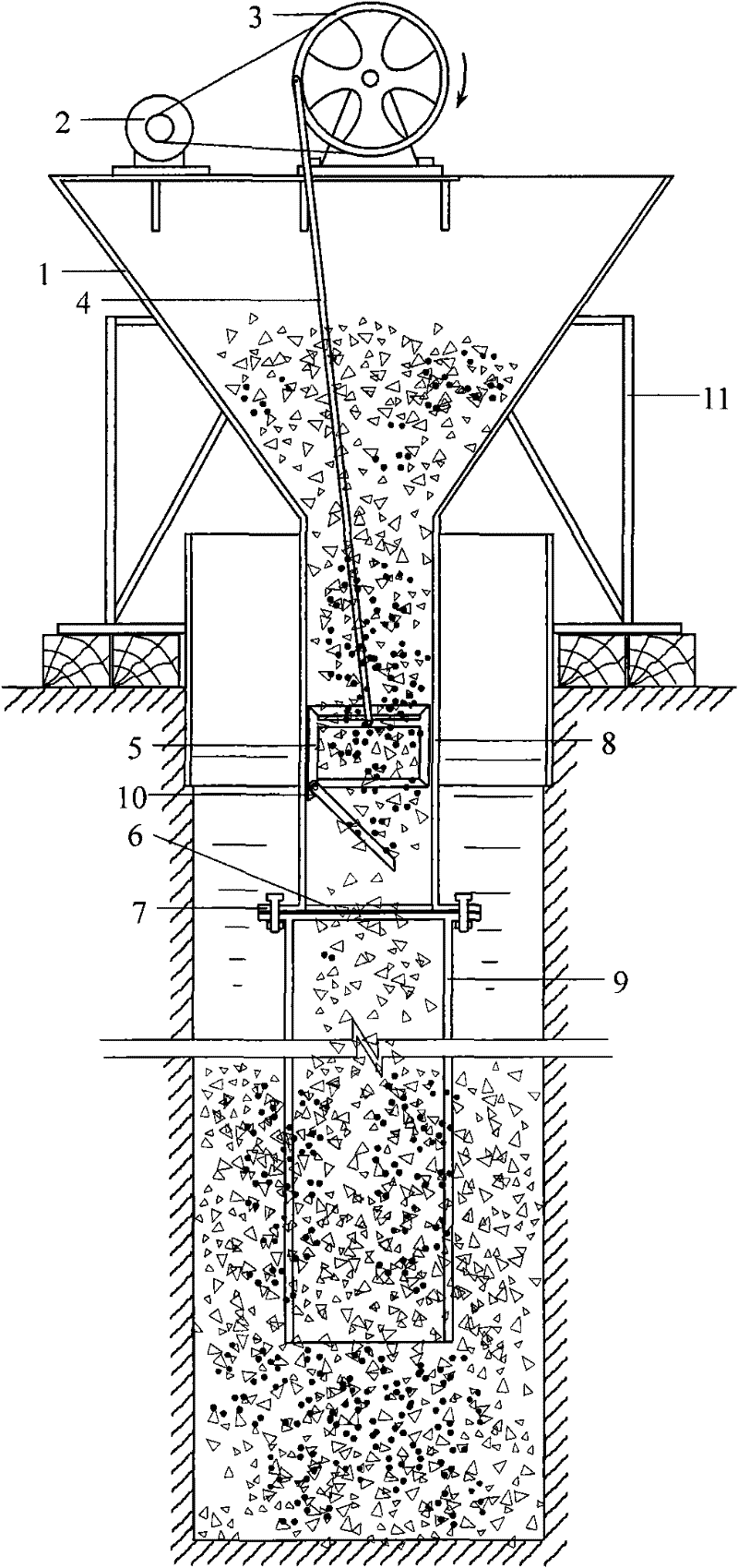

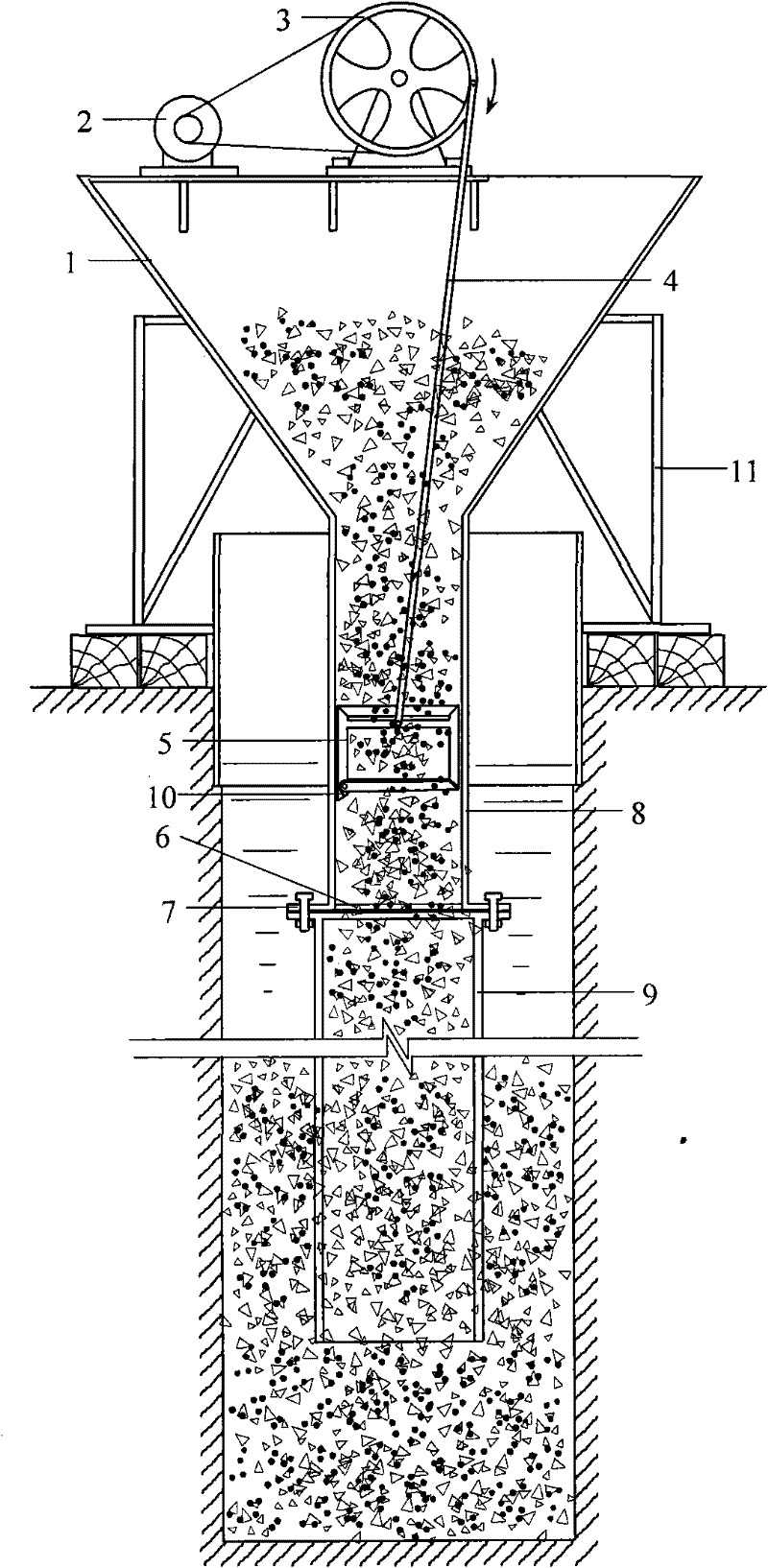

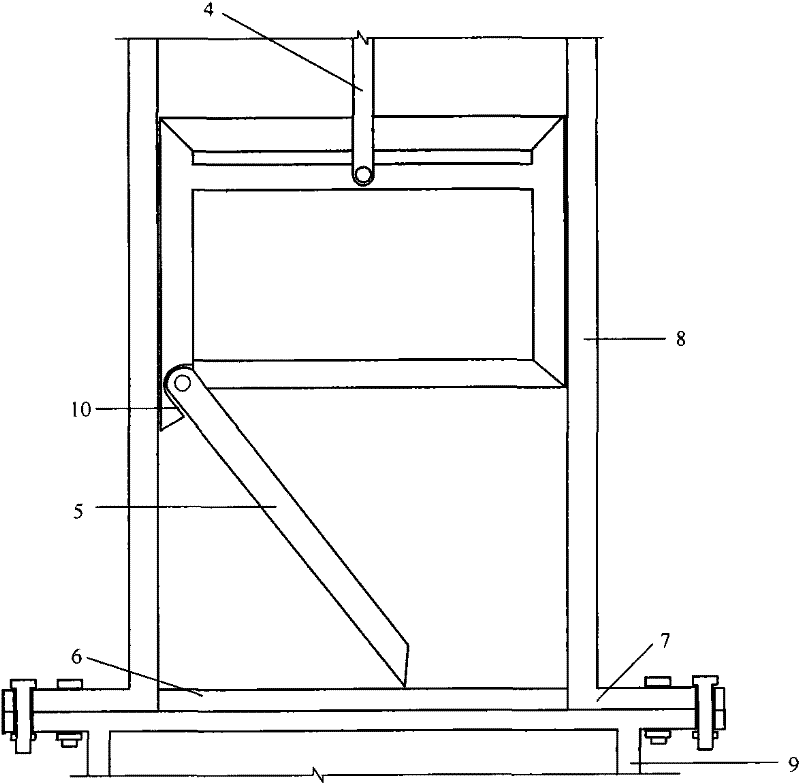

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

[0022] Depend on Figure 1-4 It can be seen that, at the pile hole after the hole is formed, the hopper 1 is placed on the hopper frame 11, and then the top end of the circular conduit 9 is connected to the square conduit 8 through the variable-section flange 7, and after the circular conduit 9 is connected section by section , down into the pile hole at a distance of 300mm to 500mm from the bottom of the hole. Start the motor 2, drive the driving wheel 3 to rotate, and when the one-way valve plate 5 is driven downward by the pulling and pressing rod 4, it touches the stop rod 6 along the mouth of the square conduit 8, and moves to the square conduit 8 along with the one-way valve plate 5 At the bottom, the stop rod 6 impels the one-way valve plate 5 to close completely, and at this moment, the motor 2 is turned off immediately. According to the pre-calculated result...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com