Full-automatic drill inlaying machine

A drilling machine, fully automatic technology, applied in the field of fully automatic drilling machines, can solve the problems of low work efficiency, unstable quality, large labor waste, etc., and achieves the solution of labor waste, scientific and reasonable design, and convenient processing of hot stamping. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

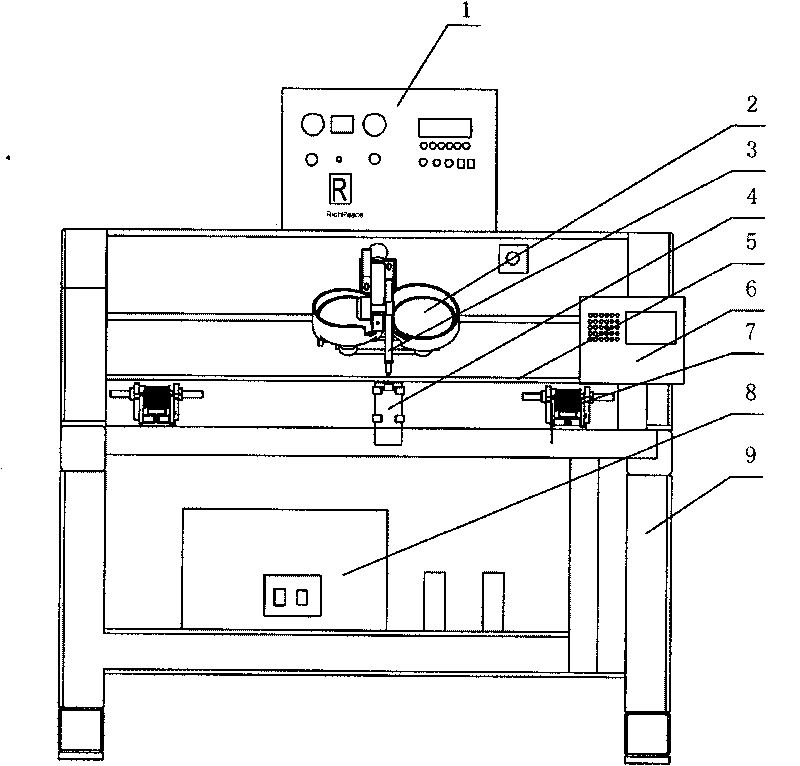

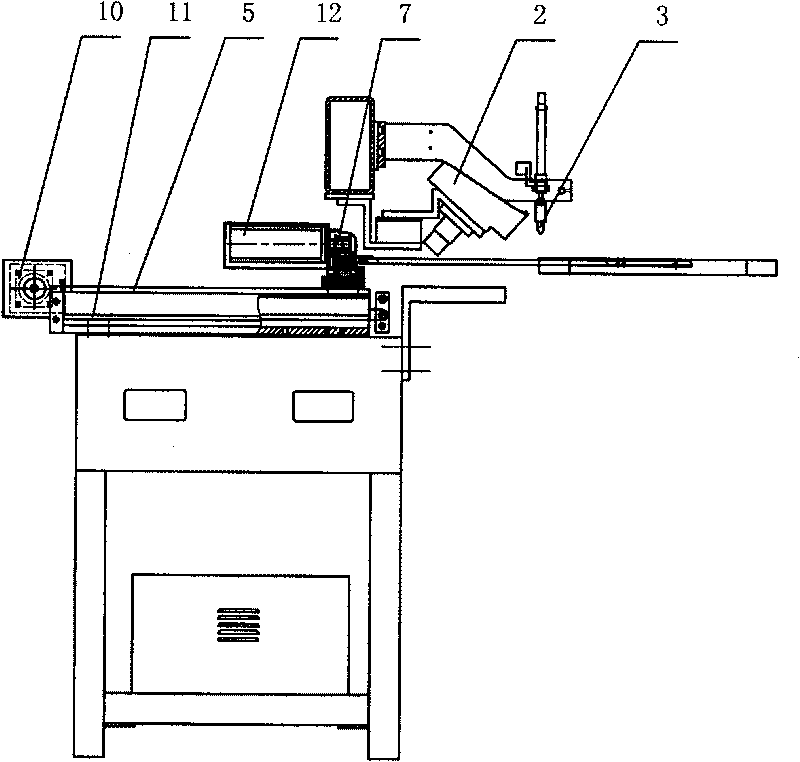

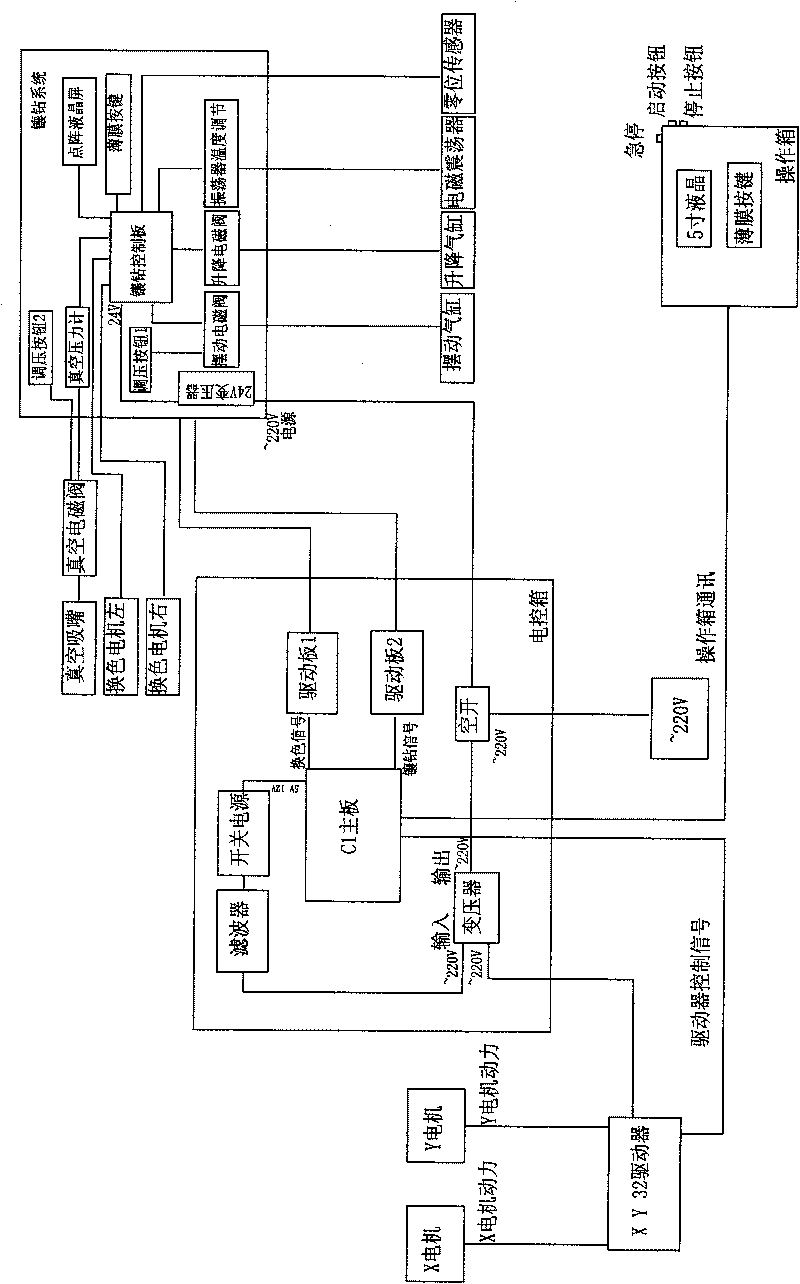

[0015] A fully automatic diamond-embedded machine, comprising an embroidery machine frame 9, a vacuum gun 3 at the head of the drill-embedded machine, a bead feeding tray 2, a cloth feeding mechanism 7, and a cloth 5 requiring diamond-embedded cloth. A horizontal embroidery frame support arm and embroidery frame (not shown in the figure) are installed on the mechanism, and the vacuum gun of the head of the drilling machine carries out diamond setting in the embroidery frame through the movement of the cloth feeding mechanism; An electromagnetic oscillator 4 is fixedly installed on the frame below the cloth below.

[0016] The innovation of the present invention is: an electric control box 8 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com