Phase-change constant-temperature material

A phase change constant temperature, raw material technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problem of irregular search for nucleating agents, and achieve easy promotion, high plasticity, and reversible phase change process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] 28% CaCl by mass 2 ·6H 2 O, 45% NaSo 4 10H 2 O, 5% Na 2 B 4 o 7 10H 2 O, 14% water, 8% cellulose. The preparation method is as follows:

[0015] (1) Put two containers separately, weigh the raw materials in proportion, and use 70°C hot water to separate the CaCl 2 ·6H 2 O and Na 2 B 4 o 7 10H 2 O dissolved and stirred, NaSo 4 10H 2 O is ground and dissolved;

[0016] (2) put NaSo 4 10H 2 Pour the O solution into a heating furnace, heat to 100°C, and maintain the container temperature at 100°C, add cellulose, and stir thoroughly;

[0017] (3) After about 10 minutes of heating, the CaCl 2 ·6H 2 O and Na 2 B 4 o 7 10H 2 The O mixed solution was also poured into the heating furnace and stirred for another 10 minutes. The entire heating process is carried out at a temperature of 100°C.

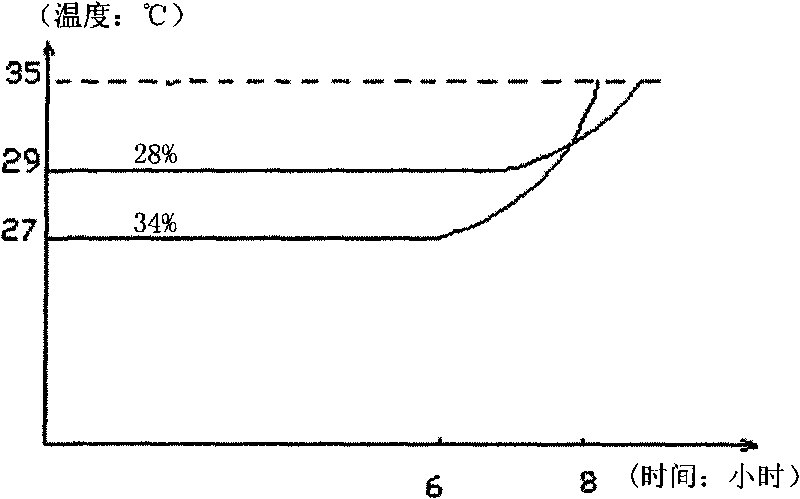

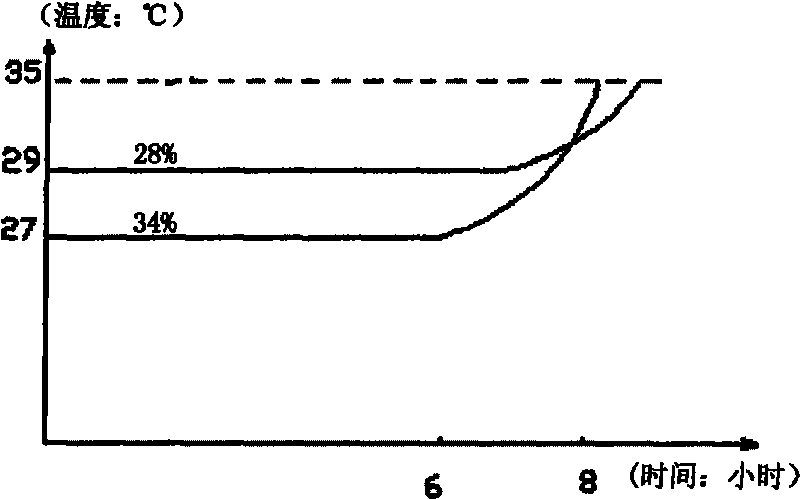

[0018] The phase change material prepared by this method has a phase change temperature of 29 degrees Celsius and a latent heat of 223KJ / KG. See attached figure 1...

Embodiment 2

[0020] 34% CaCL by mass 2 ·6H 2 O, 40% NaSo 4 10H 2 O, 8% Na 2 B 4 o 7 10H 2 O, 10% water, 8% cellulose. The preparation method is as follows:

[0021] (1) Put two containers separately, weigh the raw materials in proportion, and use 70°C hot water to separate the CaCl 2 ·6H 2 O and Na 2 B 4 o 7 10H 2 O dissolved and stirred, NaSo 4 10H 2 O is ground and dissolved;

[0022] (2) put NaSo 4 10H 2 Pour the O solution into a heating furnace, heat to 100°C, and maintain the container temperature at 100°C, add cellulose, and stir thoroughly;

[0023] (3) After about 10 minutes of heating, the CaCl 2 ·6H 2 O and Na 2 B 4 o 7 10H 2 The O mixed solution was also poured into the heating furnace and stirred for another 10 minutes. The entire heating process is carried out at a temperature of 100°C.

[0024] The phase change material prepared by this method has a phase change temperature of 27°C and a latent heat of 251KJ / KG. See attached figure 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com