Color paste for nanometer modified environmentally-friendly ferric oxide machine and preparation method thereof

An iron oxide machine, nano-modification technology, applied in the direction of pigment slurry, dyeing physical treatment, fibrous filler, etc., to achieve the effect of convenient use, good storage stability and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

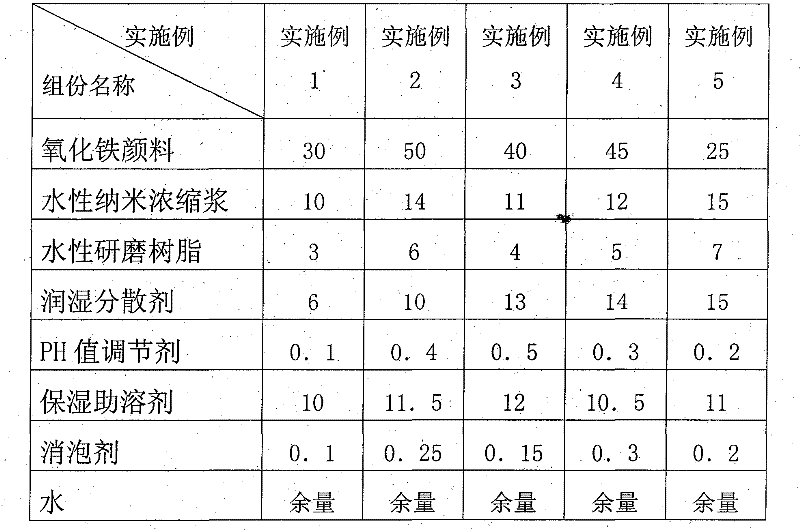

[0028] The formula of the embodiment of the present invention is referring to Table 1: Table 1: (unit: percentage by weight)

[0029]

[0030] The preparation method of nano-modified environment-friendly iron oxide machine color paste is carried out according to the following steps:

[0031] a) Put water, wetting and dispersing agent, moisturizing co-solvent, and PH value regulator into the dispersion container, adjust the rotation speed of the disperser to 500-700r / min, and obtain a uniform solution after 15 minutes, in which 10% of the total amount is reserved spare water;

[0032] b) Add water-based nano-pigment slurry, water-based grinding resin, and iron oxide pigment to the above mixed solution, adjust the dispersion speed to 800-1000r / min, and grind after 20 minutes;

[0033] c) Grinding with a horizontal sand mill, using a laser particle size analyzer to control the particle size distribution of the color paste to a d99 less than 1um in the middle process, stop gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com