Detergent and hot water solution soakage-resistance polypropylene composite

A detergent and compound-resistant technology, applied in the field of polymer composite materials, can solve the problems of easy aging of plastic parts, and achieve the effect of prolonging the service life and improving the aging resistance of heat and oxygen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

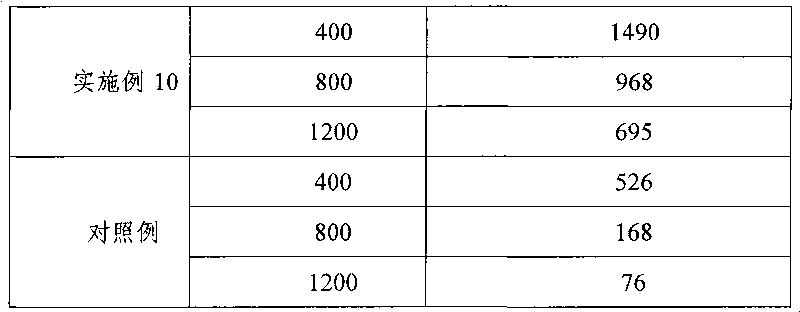

Examples

Embodiment Construction

[0020] The polypropylene composite of the present invention resistant to immersion in hot water solution of detergent, its composition and each composition weight percent are as follows:

[0021] Polypropylene resin 50%~80%

[0022] Toughener 0%~15%

[0023] Filler 5%~40%

[0024] Compound antioxidant 0.5%~1.5%

[0025] Processing aid 0.2%~0.8%

[0026] Among them: the melting index of polypropylene resin under the test conditions of 230°C and 2.16KG is 2-40g / 10min; the composite antioxidants are triazine antioxidants, phosphite antioxidants and thioether antioxidants compound.

[0027] The preparation process of the polypropylene composite resistant to immersion in hot water solution of detergent is as follows:

[0028] First, the polypropylene resin, toughening agent, filler, composite antioxidant and processing aid are weighed according to the proportion and then mixed uniformly; Pelletizing and drying are enough; wherein: the length-to-diameter ratio of the twin-scre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com