Method for preparing Silymarin

A technology of silymarin and silymarin, which is applied in the field of silymarin preparation, and can solve the problems of serious pollution, unfavorable large-scale production operations, and low silymarin content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

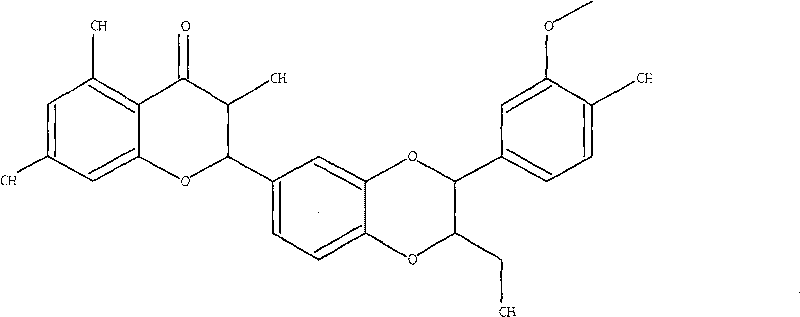

Image

Examples

Embodiment 1

[0018] Get milk thistle fruit fine powder (60 orders of particle size) 10Kg, join in CO 2 In the supercritical extractor, methanol is used as an entrainer, and the volume percentage of the entrainer in the total extraction solvent is 2%, the extraction pressure is 10MPa, the temperature is 30°C, and CO 2 The flow rate is 1ml / g crude drug / min, the extraction time is 150min, the extract is obtained, add acetone, stir to dissolve, filter, take the filtrate, concentrate, pour into a high-efficiency countercurrent extractor, and use water-acetone-chloroform (1:5:2) Solvent system, the lower phase is the stationary phase, the upper phase is the mobile phase, collect the silymarin segment, concentrate, precipitate crystals, separate the crystals, add acetone-petroleum ether (0.5:1) for recrystallization, separate, wash, and dry to obtain 9.1 g of silymarin , detected by HPLC, the purity was 91.2%.

Embodiment 2

[0020] Get milk thistle fruit fine powder (60 orders of particle size) 10Kg, join in CO 2 In the supercritical extractor, methanol is used as an entrainer, and the volume percentage of the entrainer in the total extraction solvent is 6%, the extraction pressure is 40MPa, the temperature is 60°C, and the CO 2 The flow rate is 5ml / g crude drug / min, the extraction time is 250min, the extract is obtained, add acetone, stir to dissolve, filter, take the filtrate, concentrate, inject high-efficiency countercurrent extractor, and use water-acetone-chloroform (1:5:2) Solvent system, the lower phase is the stationary phase, the upper phase is the mobile phase, collect the silymarin segment, concentrate, precipitate crystals, separate the crystals, add acetone-petroleum ether (2:1) for recrystallization, separate, wash, and dry to obtain 10.6 g of silymarin , detected by HPLC, the purity is 98.9%.

Embodiment 3

[0022] Get milk thistle fruit fine powder (60 orders of particle size) 10Kg, join in CO 2 In the supercritical extractor, methanol is used as an entrainer, and the volume percentage of the entrainer in the total extraction solvent is 4%, the extraction pressure is 30MPa, the temperature is 45°C, and CO 2 The flow rate is 2ml / g crude drug / min, the extraction time is 200min, the extract is obtained, add acetone, stir to dissolve, filter, take the filtrate, concentrate, inject high-efficiency countercurrent extractor, and use water-acetone-chloroform (1:5:2) Solvent system, the lower phase is the stationary phase, the upper phase is the mobile phase, collect the silymarin segment, concentrate, precipitate crystals, separate the crystals, add acetone-petroleum ether (1:1) for recrystallization, separate, wash, and dry to obtain 10.3 g of silymarin , detected by HPLC, the purity is 99.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com