Electric welding machine

A technology of electric welding machine and welding machine, which is applied in the direction of arc welding equipment, welding equipment, welding accessories, etc., and can solve the problems of inconvenience, inability to realize optimal allocation of resources, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

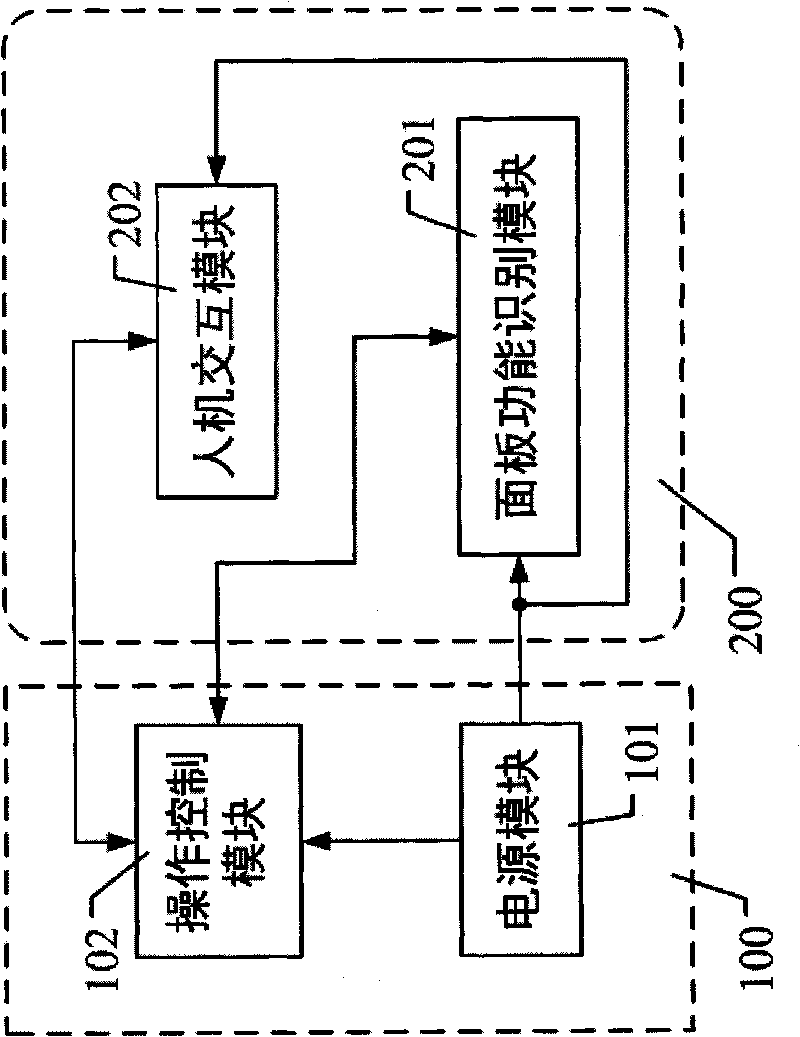

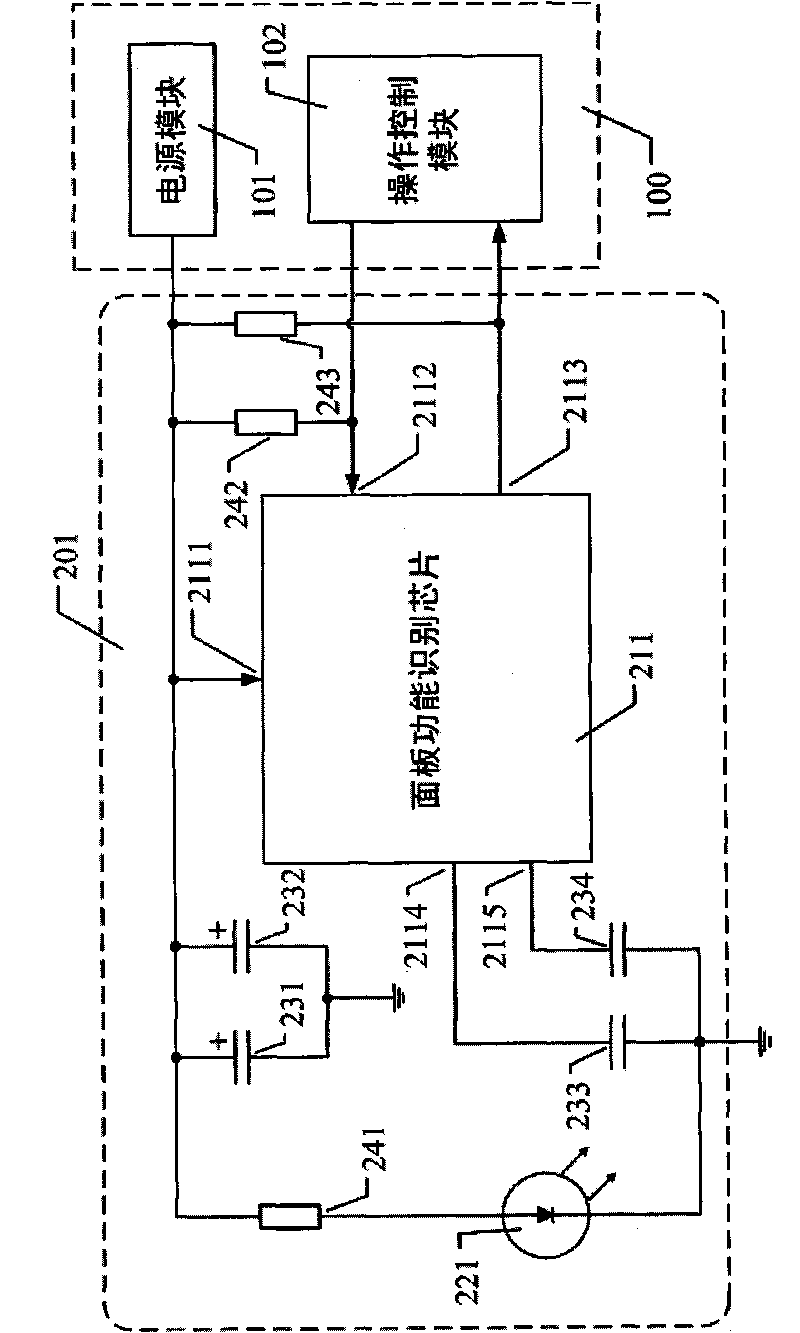

[0021] The electric welding machine of the present invention includes a welding machine body 100 and one or more detachable functional operation panels 200 . Wherein, the welding machine body 100 includes a power supply module 101 and an operation control module 102 , and the functional operation panel 200 includes a human-computer interaction module 202 and a panel function identification module 201 . The power supply module 101 supplies power to the operation control module 102, the human-computer interaction module 202, and the panel function identification module 201 respectively. Data interaction.

[0022] The above technical solutions can realize the switching between multiple functions of the electric welding machine of the present invention. The present invention separates the operation panel of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com