Fiber collimator

A fiber collimator and fiber head technology, which is applied in optics, instruments, optical components, etc., can solve problems such as obstacles to the development of fully automatic and semi-automatic equipment, and achieve the effect of eliminating the deflection angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

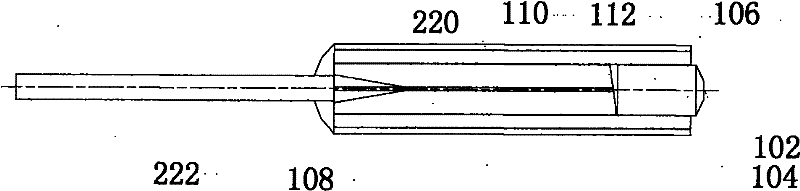

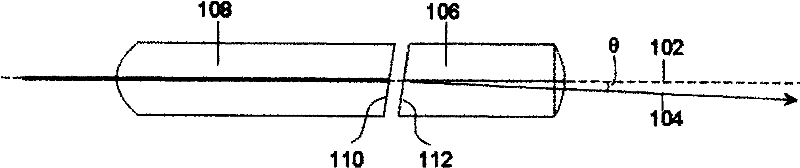

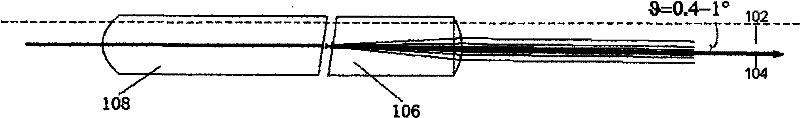

[0022] In this example, see figure 1 It can be seen that the fiber collimator includes at least one precisely positioned fiber head 108 and a collimator lens 106, a sleeve 220 for fixing the fiber head 108 and the collimator lens 106, the fiber head 108 and the collimator installed in the sleeve 220 The straight lens 106 is placed end to end in a straight line, the front end face 110 of the optical fiber head 108 is docked with the rear end face 112 of the collimator lens 106, the collimator lens 106 has an optical axis 104, and the sleeve 220 has its own central axis 102 .

[0023] The rear end face 112 of the collimating lens 106 is perpendicular to the central axis 102 of the sleeve pipe 220, and the distance between the rear end face 112 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com