Radial magnet conducting iron core cake forming machine

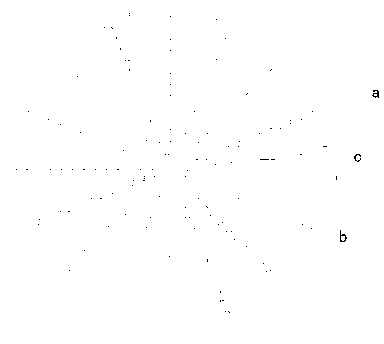

A molding machine, radial technology, applied in the manufacture of inductors/transformers/magnets, electrical components, parts of transformers/inductors, etc., can solve the eddy current loss of the amplitude magnetic force line passing through the silicon steel sheet, low magnetic cross-section, and time-consuming production The problem of laboriousness and other problems can be achieved by omitting the filling and curing molding steps, improving the effective magnetic cross-section, and reducing the cost of mold production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

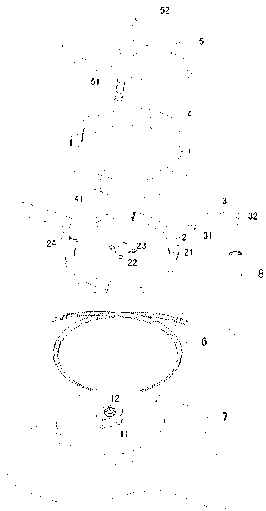

[0019] see image 3 . The forming machine is composed of a frame, a rotating tray 1 and a forming assembly arranged on the frame. The forming assembly consists of a bearing plate 2, an outer ring 4, a central fixed circular tube 8, four partition partitions 3 and a wire rope ring 6 And tightening device thereof, and top cover 5 forms.

[0020] The rotary tray 1 is positioned on the worktable 7 and is fixed on the shaft end of a vertical rotating shaft driven by a motor. The carrying plate 2 rests on the rotating tray 1 through the cooperation of the tenon hole 22 and the tenon 11, and the two are connected as a whole so as to rotate together. A protruding ring 21 is provided on the edge of the disc surface of the carrying disc 2 , and four concave grooves 24 are equally spaced on the protruding ring 21 . The four partition partitions 3 are vertically positioned radially on the disk surface of the carrying disk 2 . The height of the partition partition 3 should be lower tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com