Railway track welded steel and manufacturing technology thereof

A railway track and welding steel technology, applied in the field of metallurgical manufacturing, can solve the problems of unreasonable heat treatment system, affecting the quality of welds, low performance indicators, etc., and achieve a reasonable chemical composition ratio, good alloying effect, and high performance indicators. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

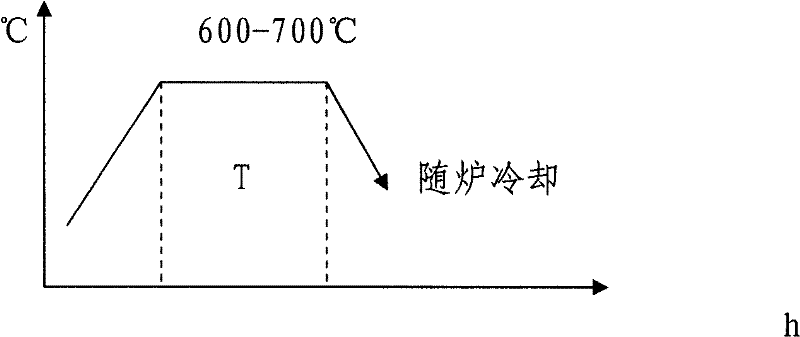

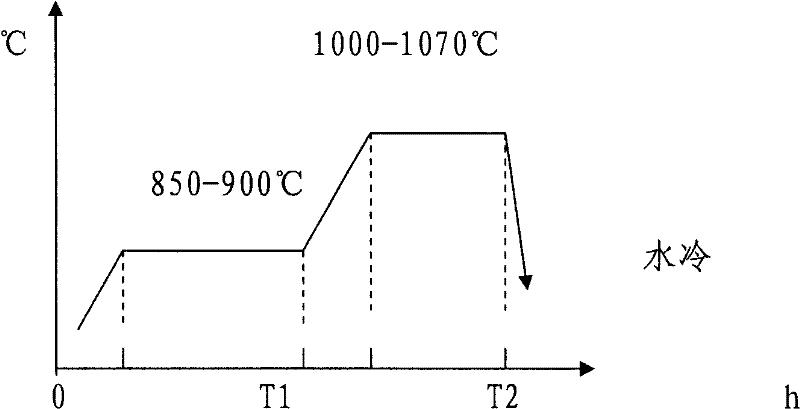

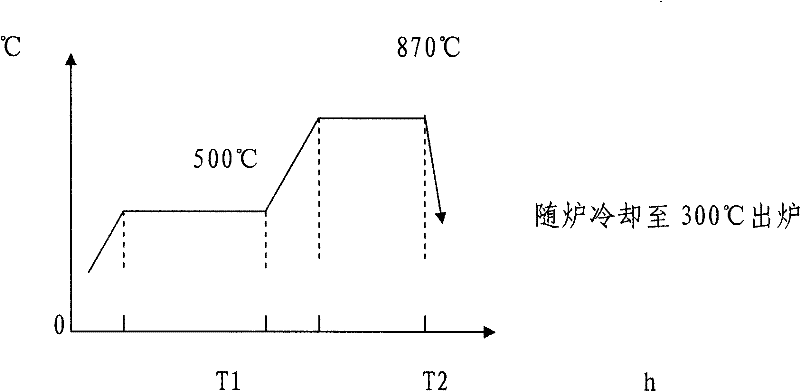

Method used

Image

Examples

Embodiment ( 1

[0049] Welded with 60kg / M track, used at the lowest temperature -50°C (suitable for alpine regions)

[0050] 1. Selected chemical composition range: (%)C: 0.05-0.09; Si≤0.3; Mn: 4-5; Cr: 16-17; Ni: 12-13; Mo: 1.1-1.5; P≤0.02; S ≤0.01; Ti: 0.1-0.15Cu≤0.15 Fe: 62.79-65.85

[0051] 2. Formulate the ingredients according to the range of chemical composition: electrolytic manganese 5%, electrolytic chromium 16.8%, pure nickel plate 12.8%, pure molybdenum rod 1.4%, pure titanium 0.13%, industrial pure iron 63.87%.

[0052] The above-mentioned raw materials should be inspected, and their purity should not be lower than 99.9%.

[0053] 3. Intermediate frequency smelting: use alkaline furnace lining, bake before use, the baking temperature is 200-300 ℃, and the baking time is 6-8 hours. Except for electrolytic manganese, the remaining raw materials are put into the furnace. Put the electrolytic manganese into the furnace 30 minutes before coming out of the furnace. Sampling and ins...

Embodiment ( 2

[0079] Welded with 54kg / M track, the operating environment temperature is -10-40°C (suitable for hot and humid areas)

[0080] 1. Selected chemical composition range: (%)C: 0.08-0.12; Si≤0.3; Mn: 5-6; Cr: 17-18; Ni: 10-11; Mo: 0.9-1.2; P≤0.02; S≤0.01; Ti: 0.2-0.3; Cu≤0.15; Fe: 62.9-66.82

[0081] 2. Formulate the ingredient plan according to the chemical composition range: electrolytic manganese 6%, electrolytic chromium 18%, pure nickel plate 11%, pure molybdenum rod 1.2%, pure titanium 0.25%, industrial pure iron 63.55%; the above raw materials should be inspected, Its purity should not be lower than 99.9%.

[0082] 3. Intermediate frequency smelting: the same as application example 1.

[0083] 4. Electroslag remelting (refining): same as application example 1.

[0084] 5. Annealing: Same as application example 1.

[0085] 6. Blanking: Use a high-speed metal band saw, and the cutting weight is 39kg / piece.

[0086] 7. Forging: Same as application example 1.

[0087] 8. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com