Method for preparing poplar fiber /Al2O3 nano composite material

A nano-composite material and poplar fiber technology, which is applied in the field of poplar fiber/Al2O3 nanocomposite material preparation to achieve the effect of solving poor dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

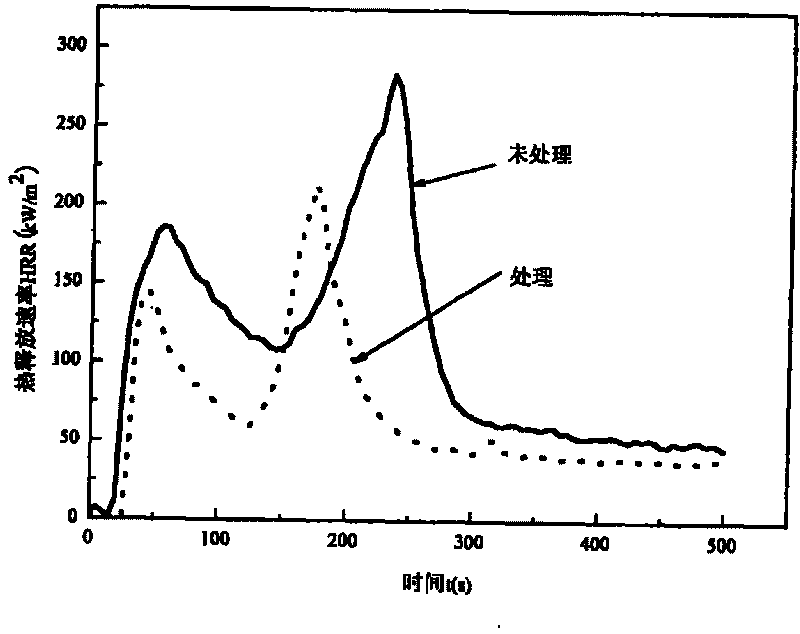

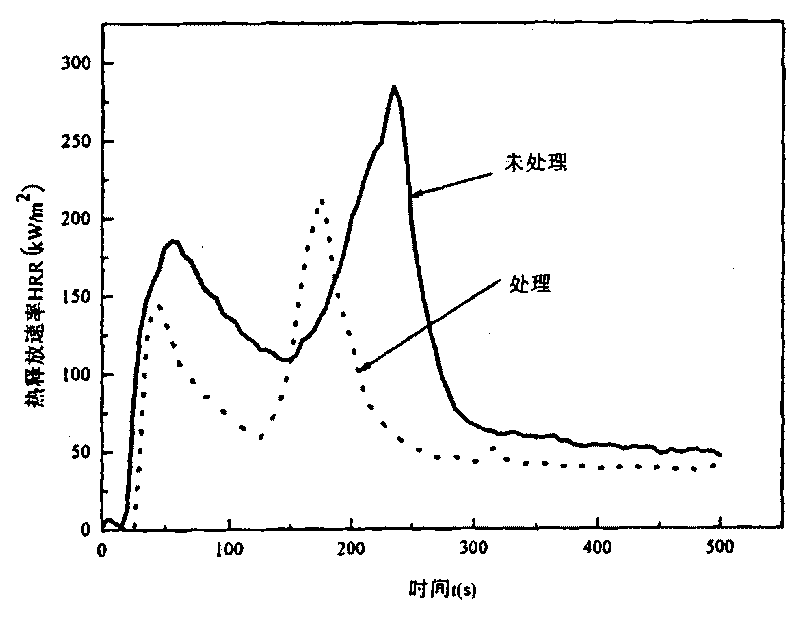

[0025] The test piece was cut from the prepared composite material, with a size of 10cm×10cm×6mm, and the CONE experiment was carried out on it with a cone calorimeter from FireTesting Technology in the UK; in order to make the experimental temperature close to the actual fire temperature, the thermal radiation power of 50kW was used in this experiment .m -2 ;In order to reduce the influence of the outside world, wrap all the surfaces of the sample except the heating surface with aluminum foil, put them in the stainless steel sample holder, and use heat-insulating cotton to block the heat transferred from the back of the sample to the outside.

[0026] Heat release rate HRR. Blank fiberboard with poplar fiber / Al 2 o 3 The HRR-t curve of inorganic nanocomposites is shown in figure 1 . Blank fiberboard and poplar fiber / inorganic nano-Al 2 o 3 The heat release characteristic values of the composite materials are shown in Table 2.

[0027] Table 2 The heat release charact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com