Continuous-casting crystallizer simulation method by taking shell thickness and flowing quality balance into consideration and device thereof

A continuous casting crystallizer and mass balance technology, which is applied in the direction of instruments, calculations, electrical digital data processing, etc., can solve the problems that cannot reflect the real situation of continuous casting, and achieve the effect of improving the quality of casting slabs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below.

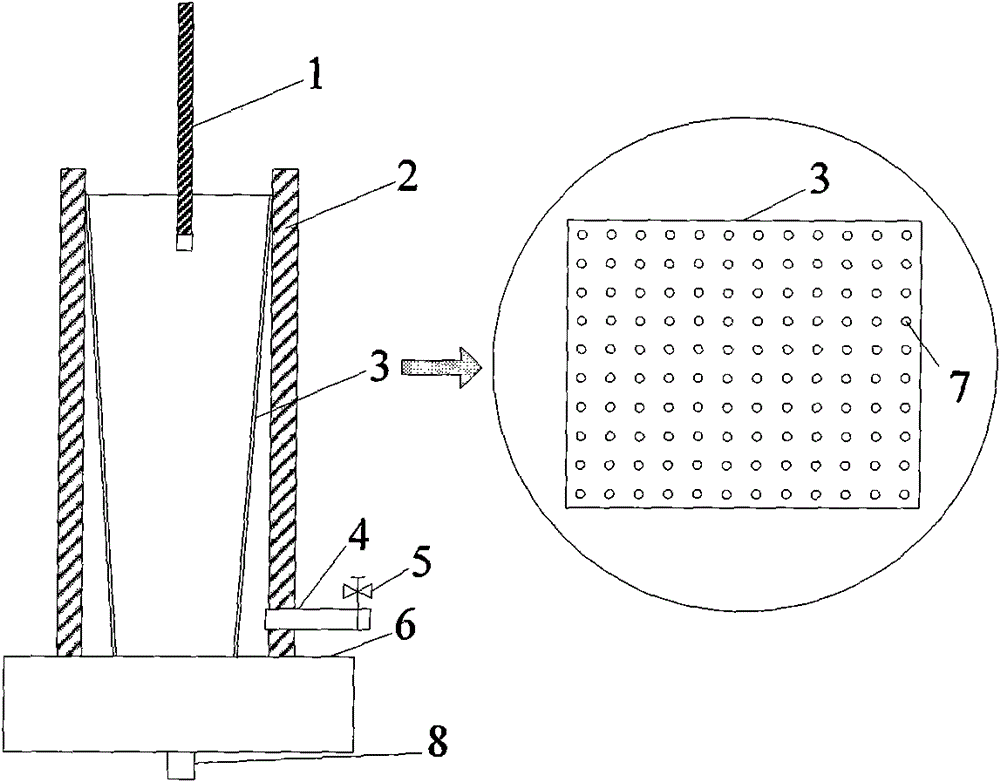

[0028]In order to truly reflect the changing law of the mold flow field in the continuous casting process and to make the research results of nozzle structure optimization more accurate, in the process of physical simulation research, the solidification of molten steel and the occurrence of the total amount of molten steel after it is transformed into a solidified shell should be considered. Effect of changes on crystallizer flow regime and nozzle optimization results. Before and after considering the solidification shell and flow mass balance, the flow state in the crystallizer changes greatly. On the one hand, it is the change of the flow space: considering the thickness of the solidification shell, the flow area in the crystallizer will shrink to a certain extent, and the total flow space will be reduced. Moreover, due to the existence of the solidification shell, the upper backflow stream generated by the outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com