Homogenizer

A homogenizer and unified technology, applied to chemical instruments and methods, emulsification, fluid mixers, etc., can solve the problems of increased energy consumption of power equipment, difficulty in mixing uniformly, increased maintenance costs, etc., to increase the degree of homogenization, Ease of use and improved homogenization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

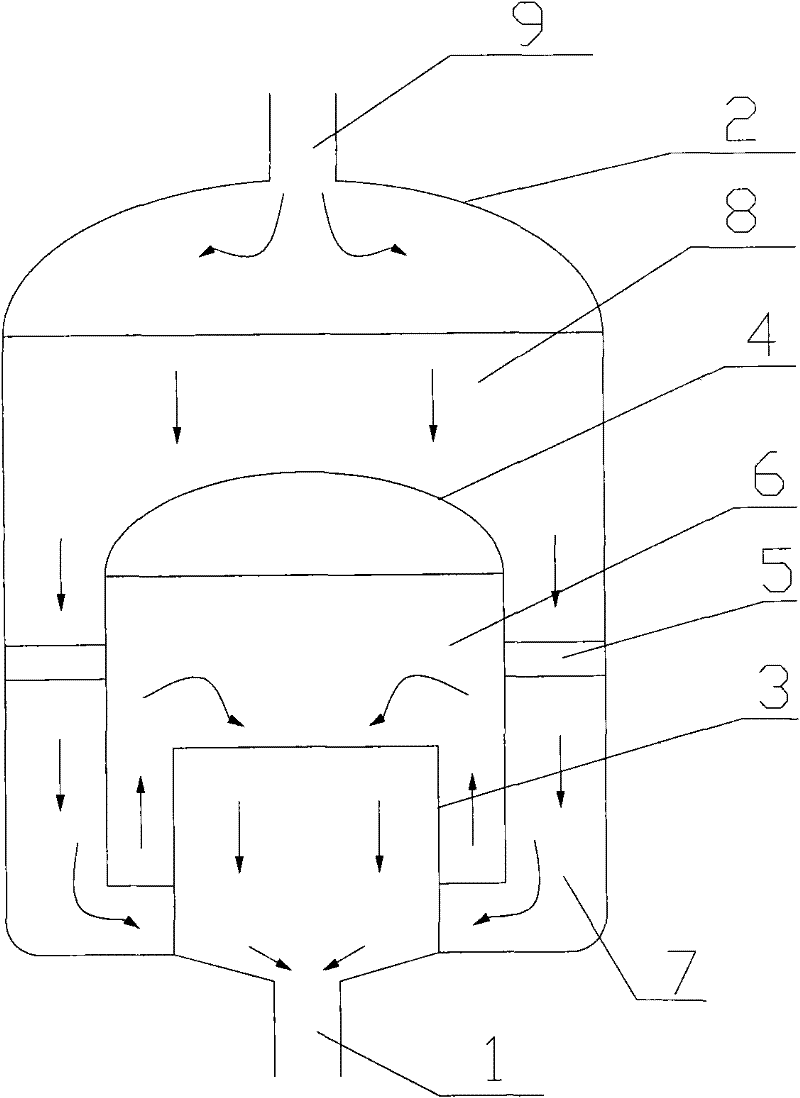

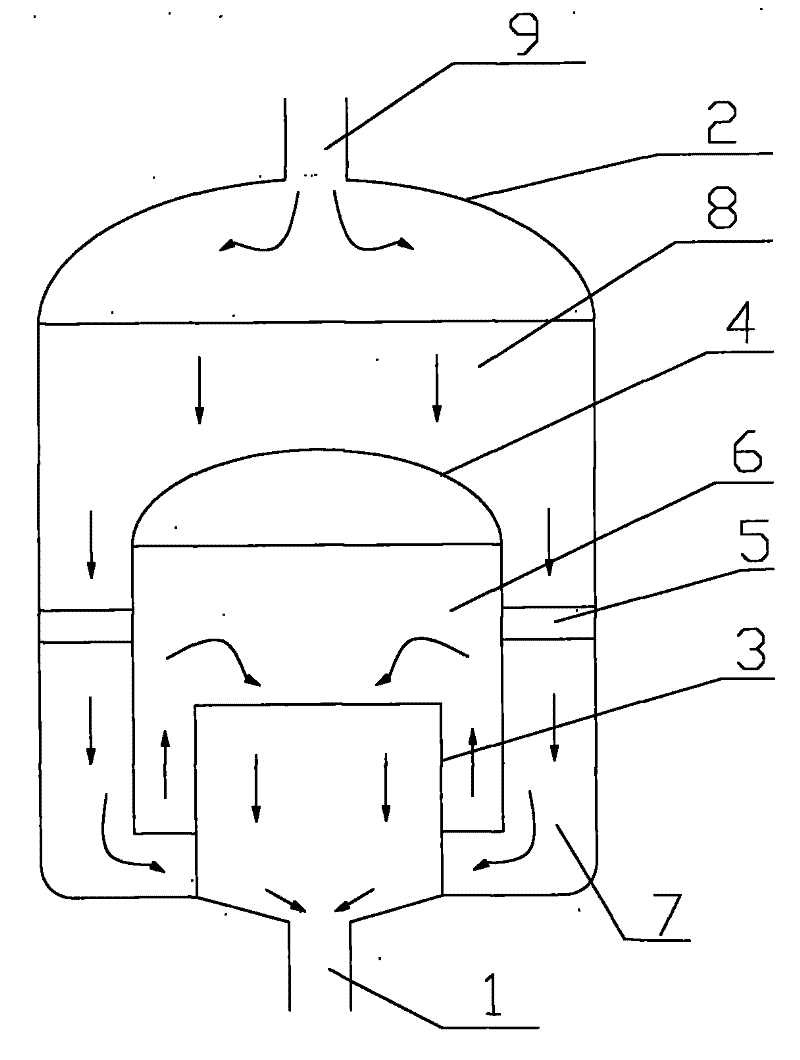

[0033] attached figure 1 As shown, the device has a total of three concentric cylinders, the innermost first cylinder 3 has no cover, and its height is 2 / 3 of the second cylinder 4 with a cover. The second cylinder 4 passes through the fixing bar. Connected with the outermost first cylinder 2, the height of the second cylinder 4 is half of the height of the first cylinder 2, and the distance from the bottom edge of the second cylinder to the bottom of the homogenizer is 1 / 4 of the height of the first cylinder 3 ~1 / 3. The radius of the first cylinder 3 is 2 / 3 of the second cylinder 4 , and the radius of the second cylinder 4 is 2 / 3 of the first cylinder 2 . The mixed material enters the second cylinder 4 through the cavity 7 composed of the first cylinder 2 and the second cylinder 4 in the direction of the arrow according to the direction of the arrow, and the second cylinder 4 is fixed with the first cylinder 2 outside by the fixing strip The material is pushed up by the mat...

Embodiment 2

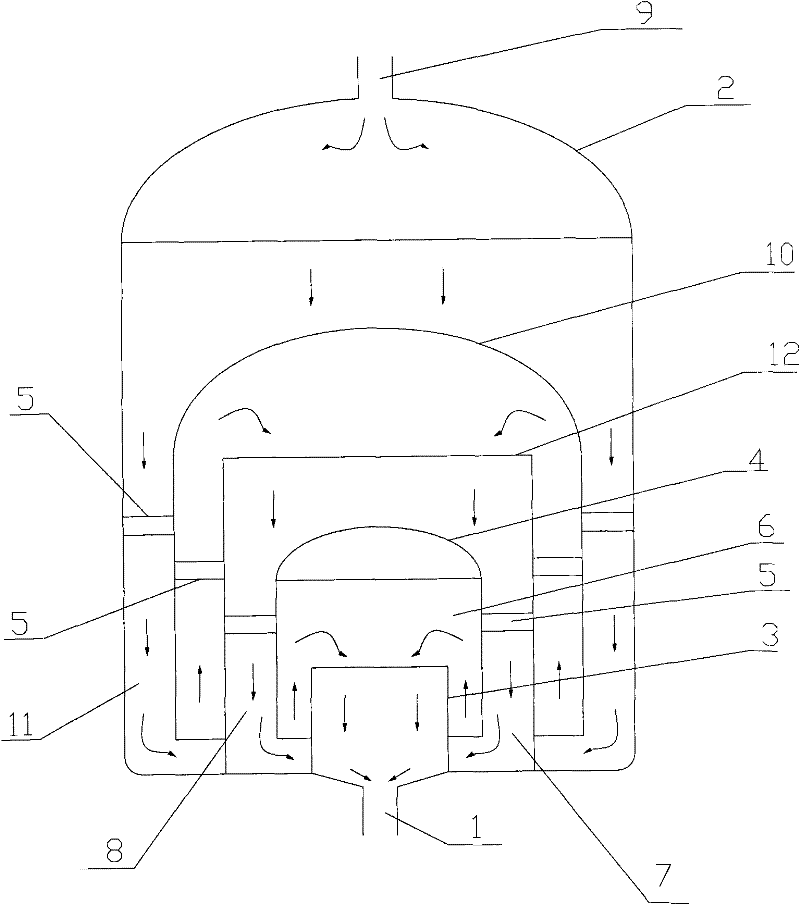

[0035] attached figure 2As shown, the device consists of 5 coaxial cylinders in total, including 3 first cylinders and 2 second cylinders, which are coaxially sleeved with each other. The innermost first cylinder 3 has no cover, its height is 2 / 3 of the covered second cylinder 4, the radius of the first cylinder 3 is 2 / 3 of the second cylinder 4, and the bottom of the second cylinder 4 The height from the edge to the bottom of the homogenizer is 1 / 4 of the height of the first cylinder 3, and the second cylinder 4 is connected to the first cylinder 12 set outside it through the fixing strip 5; the height of the second cylinder 4 is the first 1 / 2 of the height of the cylinder 12, the radius of the second cylinder 4 is 2 / 3 of the first cylinder 12, the top of the first cylinder 12 is open, and the bottom shares a bottom with the homogenizer; the second cylinder with a cover The cylinder 10 is sleeved on the outside of the first cylinder 12, the height of the first cylinder 12 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| intrinsic viscosity | aaaaa | aaaaa |

| intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com