Hot-water brewing mechanism and system with low power and abundant water supply

A low power, hot water technology, applied in the field of brewing system and hot water brewing mechanism, can solve the problems of energy waste, cost burden, difficult to obtain, etc., and achieve the effect of improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

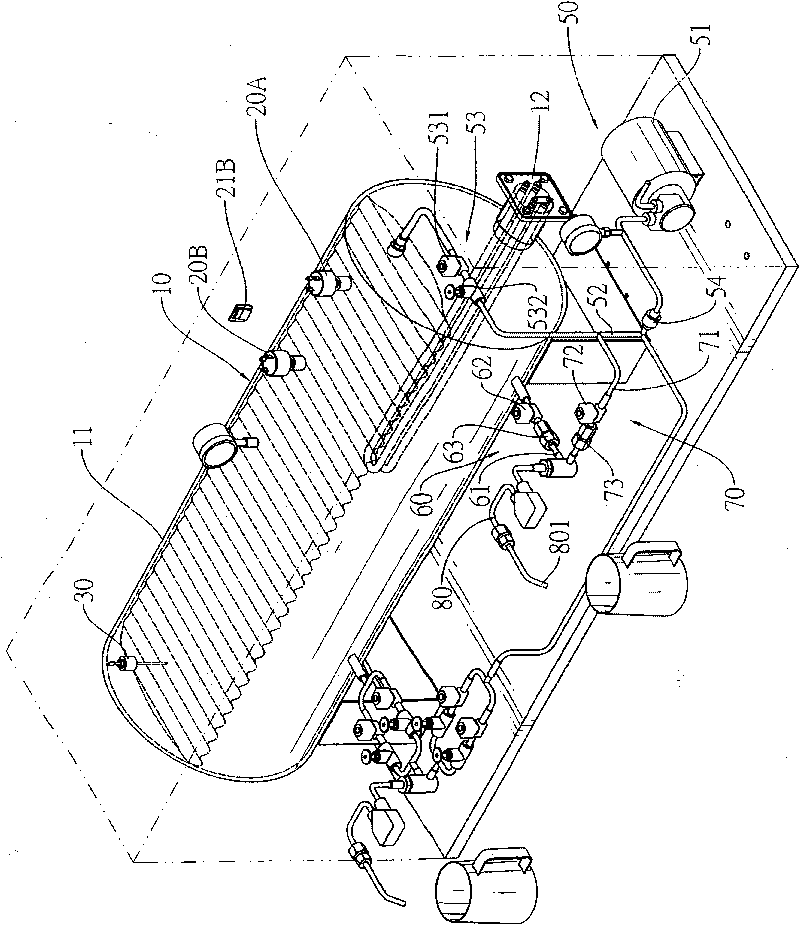

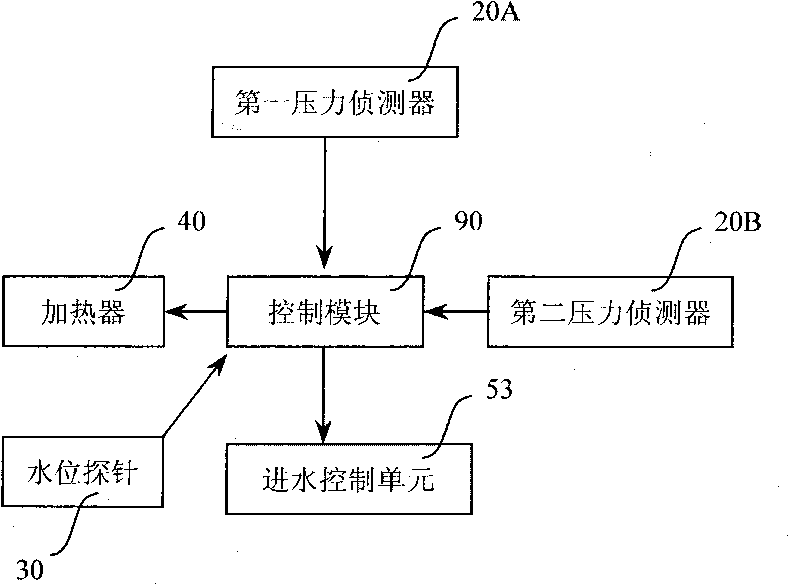

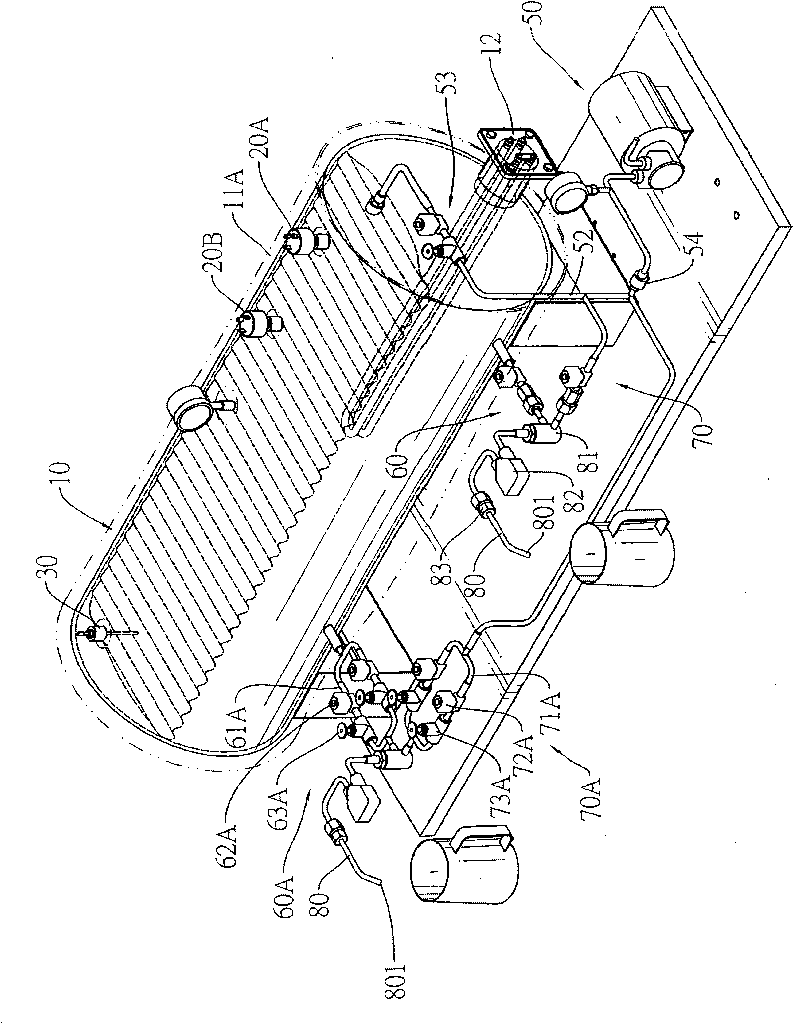

[0039] Please refer to figure 1 As shown, the low-power hot water brewing mechanism for a large amount of water supply of the present invention includes a boiler 10, a water inlet unit 50, a first pressure detector 20A, a second pressure detector 20B, a water level The probe 30 and at least one water supply unit, the aforementioned mechanism can be used in a hot water brewing system for brewing beverages such as coffee and tea.

[0040] The boiler 10 includes a furnace body 11 and a heater 12, wherein a tank is formed in the furnace body 11 for water storage; and the heater 12 is arranged in the furnace body 11 for heating the container water in the tank.

[0041]The water inlet unit 50 is connected to the boiler 10 and includes a pump 51, a cold water pipe 52, a water inlet control assembly 53 and a check valve 54, wherein the cold water pipe 52 is connected to the furnace body 11 of the boiler 10 and the pump 51 , for the pump 51 to deliver water to the tank of the furnac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com