Natural food preservative for fruit and preparation method thereof

A technology of natural food and preservatives, applied in the field of natural food preservatives and natural food preservatives for fruits, can solve problems such as poisoning health, pollute the environment, etc., and achieve the promotion of plant resources, convenient circulation, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

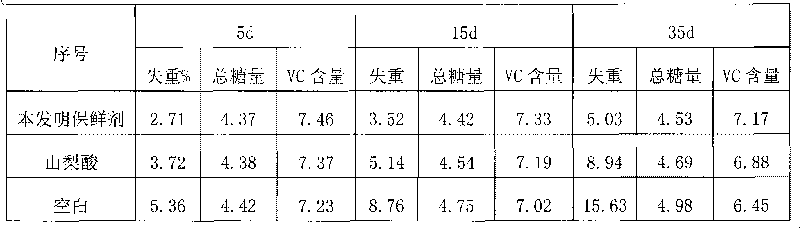

Image

Examples

Embodiment 1

[0015] Embodiment one: the preparation of antistaling agent 1

[0016] (1) take by weighing fresh aloe 3Kg and fresh pine needle 0.7Kg respectively, wash, mix after chopping;

[0017] (2) Put the above mixture into a multifunctional extraction tank, add 18.5Kg of water, adjust the pressure of the extraction tank to 2Mpa, and the temperature to 30°C, extract twice for 2 hours each time, and combine the extracts.

[0018] (3) The extract was left to settle for 24 hours, and the supernatant was taken from top to bottom and filtered through a multilayer screen of 60 mesh, 100 mesh, 200 mesh and 400 mesh.

[0019] (4) Put the filtrate into a vacuum concentration tank and concentrate at 4°C to obtain an extract.

[0020] (5) The extract is dried by a drying tower, and after drying, it is pulverized to 150 mesh by a universal pulverizer to obtain 1.21Kg powder, which is preservative 1.

Embodiment 2

[0021] Embodiment two: the preparation of antistaling agent 2

[0022] (1) take by weighing fresh aloe 5.0Kg and fresh pine needle 1.3Kg respectively, wash, mix after chopping;

[0023] (2) Put the above mixture into a multifunctional extraction tank, add 31.5Kg of water, adjust the pressure of the extraction tank to 2MPa, and the temperature to 35°C, extract twice for 2 hours each time, and combine the extracts.

[0024] (3) The extract was left to settle for 24 hours, and the supernatant was taken from top to bottom and filtered through a multilayer screen of 60 mesh, 100 mesh, 200 mesh and 400 mesh.

[0025] (4) Put the filtrate into a vacuum concentration tank and concentrate at 4°C to obtain an extract.

[0026] (5) The extract is dried by a drying tower, and after drying, it is pulverized to 150 mesh by a universal pulverizer to obtain 1.91Kg powder, which is preservative 2.

Embodiment 3

[0027] Embodiment three: the preparation of antistaling agent 3

[0028] (1) Take by weighing fresh aloe 4.0Kg and fresh pine needle 1.0Kg respectively, wash, mix after chopping;

[0029] (2) Put the above mixture into a multifunctional extraction tank, add 25Kg of water, adjust the pressure of the extraction tank to 2MPa, and the temperature to 38°C, extract twice for 2 hours each time, and combine the extracts.

[0030] (3) The extract was left to settle for 24 hours, and the supernatant was taken from top to bottom and filtered through a multilayer screen of 60 mesh, 100 mesh, 200 mesh and 400 mesh.

[0031] (4) Put the filtrate into a vacuum concentration tank and concentrate at 4°C to obtain an extract.

[0032] (5) The extract is dried by a drying tower, and after drying, it is pulverized to 150 mesh by a universal pulverizer to obtain 1.52Kg powder, which is preservative 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com