Intelligent plant building illumination control method and system

A lighting control system and intelligent control technology, applied in the field of lighting, can solve the problems of energy waste that cannot be realized intelligently and increase the labor intensity of workers, and achieve the effects of improving labor intensity and working environment, low manufacturing cost, and powerful functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

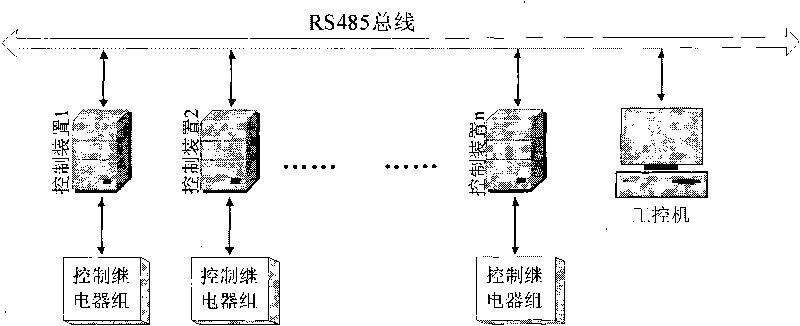

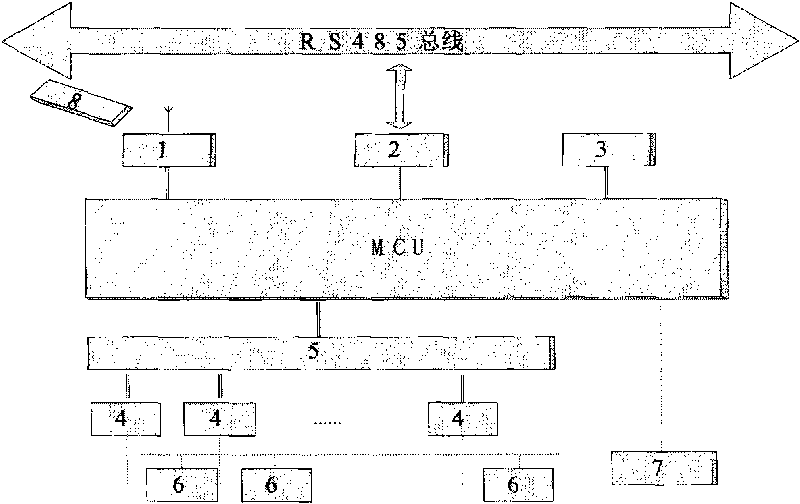

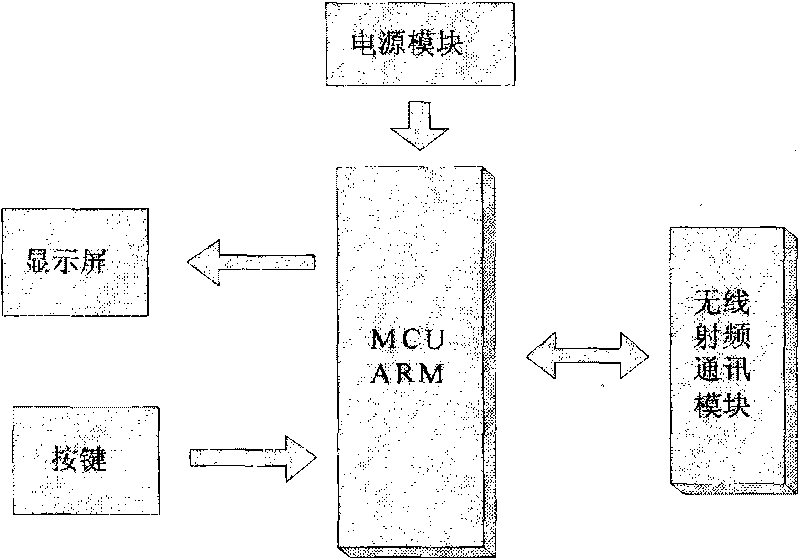

[0044] like figure 1 , 2 , as shown in 3:

[0045] An intelligent factory lighting control method, the steps are as follows:

[0046] 1. Several intelligent control devices are used to form a plant lighting intelligent control network through the RS485 bus and a host; the plant intelligent lighting control network The slave of the RS485 master-slave communication protocol is the RS485 communication interface of each intelligent control device;

[0047] 2. Install each intelligent control device in each lighting control box respectively. The intelligent control device is mainly composed of a central controller, a lamp main circuit 6 and a hand-held remote control. The remote control communication adopted is radio frequency communication, and the hand-held The remote control controls multiple intelligent control devices to realize remote control of each lamp in the factory building.

[0048] 3. The central controller used has an integrated RS-485 communication interface. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com