Self-clinching chucking busbar elastic wire clip

A technology of self-tightening clamping and elastic clamps, which is applied in the direction of overhead lines, current collectors, electrical components, etc., can solve the problems that the damage of the joint surface cannot be effectively avoided, and achieve good current receiving effect, reduce wear and tear, and achieve insulation levels high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

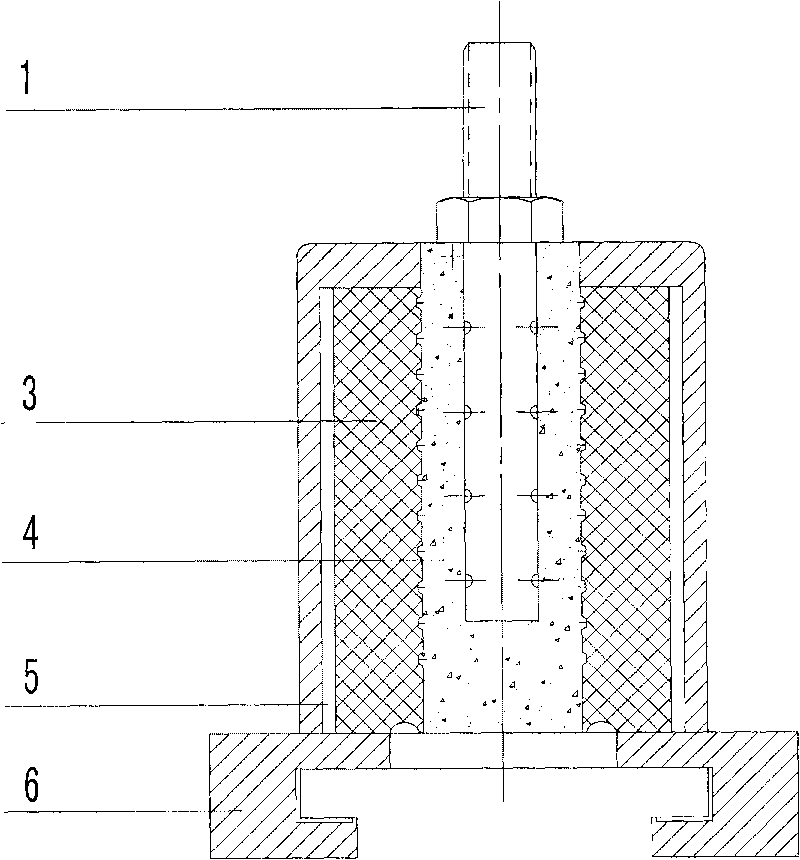

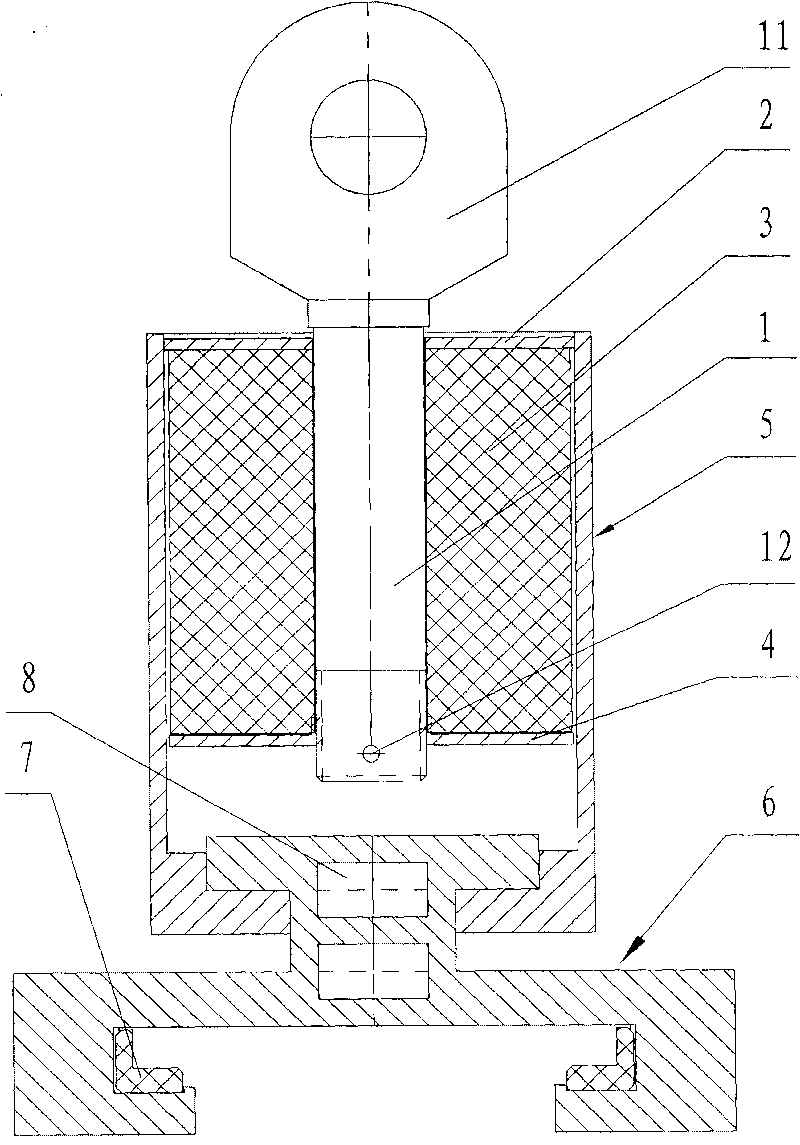

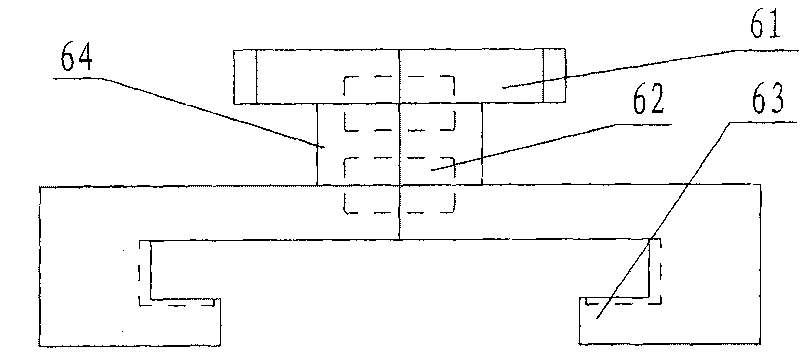

[0019] refer to figure 2 , the self-tightening busbar elastic clamp used for the overhead rigid catenary of the electrified railway, including the hanging rod 1 used to connect with the steel beam, and the top connecting head 11 is made with a through hole for passing the insulator and the steel beam. rack suspension connection. The cylinder body 5 is made of stainless steel, and a cylindrical rubber elastic layer 3 with a shaft hole is installed inside. The thickness of the rubber elastic layer is selected within the range of 10-65mm under the premise of ensuring the elastic force. There is a gap between the cylinder wall 51 and the rubber elastic layer 3 for the rubber elastic layer to be compressed and deformed. The top and bottom surfaces of the rubber elastic layer are respectively provided with a top plate 2 and a bottom plate 4, and the top plate 2 is welded to the top of the cylinder body. , constitute the top cover of cylinder 5. The diameter of the bottom plate 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com