Indoor detection method for performance of waterproof adhesive layer material of cement concrete bridge

A waterproof bonding layer, cement concrete technology, applied in the direction of analyzing materials, using a stable shear force to test the strength of materials, measuring devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

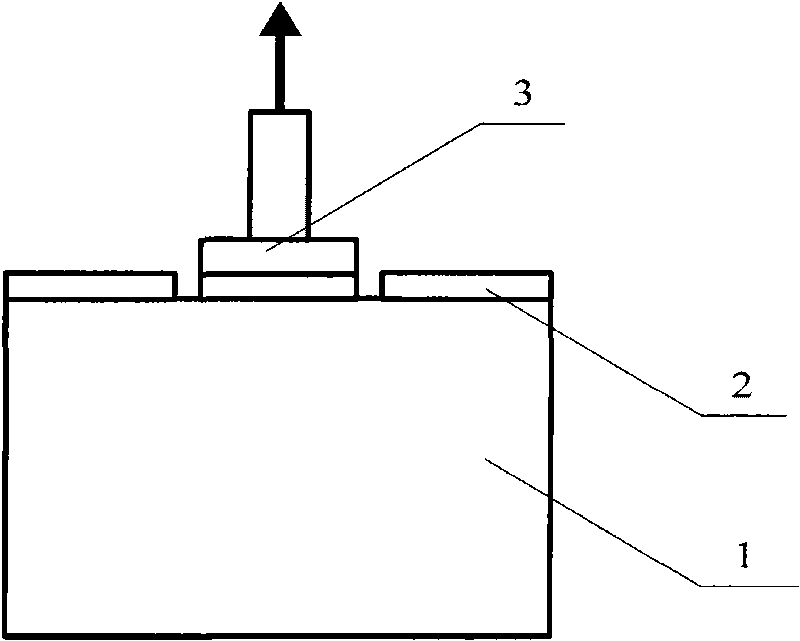

Image

Examples

Embodiment 1

[0034] 1. Sample preparation

[0035] 1) Prepare cement concrete specimens with strength grade of C30 according to "General Concrete Mix Proportion Design Regulations" (JGJ / T 55-1996), with a thickness of 40mm~50mm, length and width of 100mm, curing for 21 days, and cleaning after completion Surface floating slurry, to ensure that the construction surface is clean and free of defects;

[0036] 2) The three kinds of waterproof adhesive layer materials are constructed and maintained according to their respective construction techniques.

[0037] 2. Normal temperature (25℃) bond strength test

[0038] Take the cement concrete specimen after the construction and curing of the waterproof adhesive layer, and fix the slider on the surface of the waterproof adhesive layer with epoxy glue. After the epoxy glue is completely cured, place the specimen at a constant temperature of 24.5-25.5℃ Cure in the box for 24 hours, and then use a tensile testing machine to measure the bonding strength of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com