Space environmental temperature and humidity control method and control device thereby

A technology of temperature and humidity control and space environment, applied in the direction of non-electric variable control, space heating and ventilation, control/regulation system, etc., can solve the problems of affecting temperature, large energy consumption, energy waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

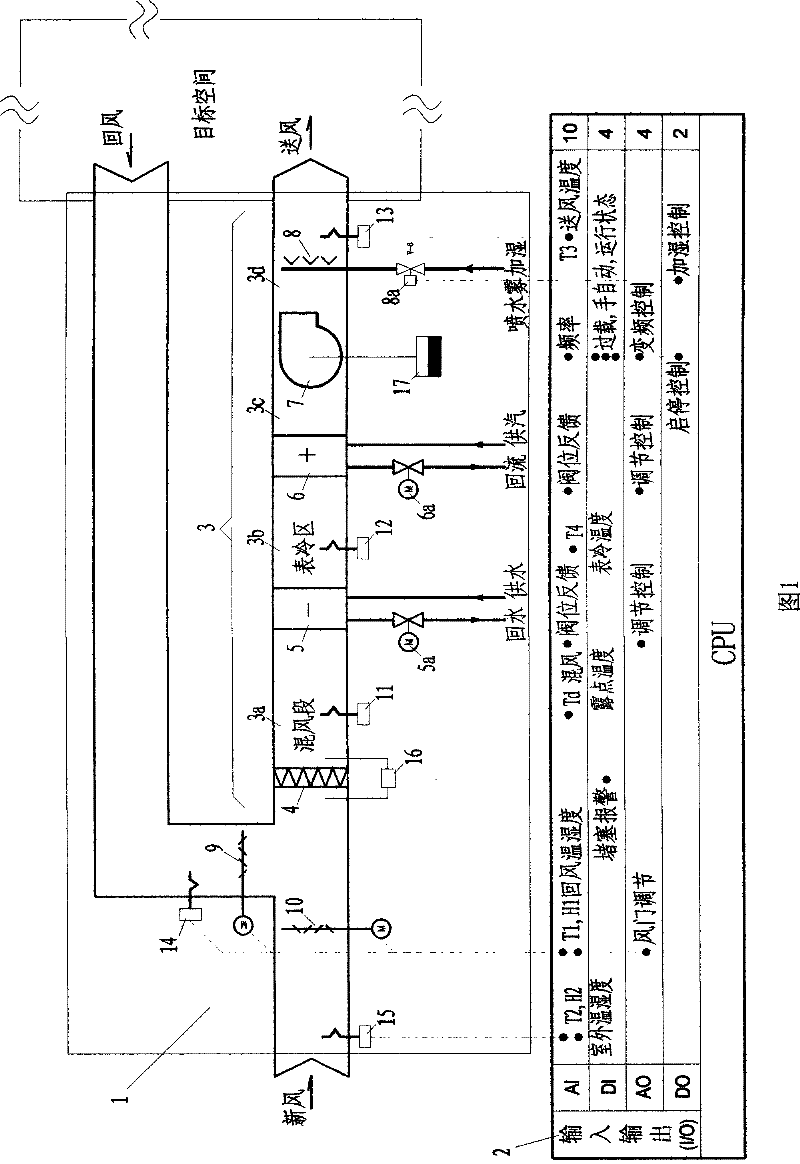

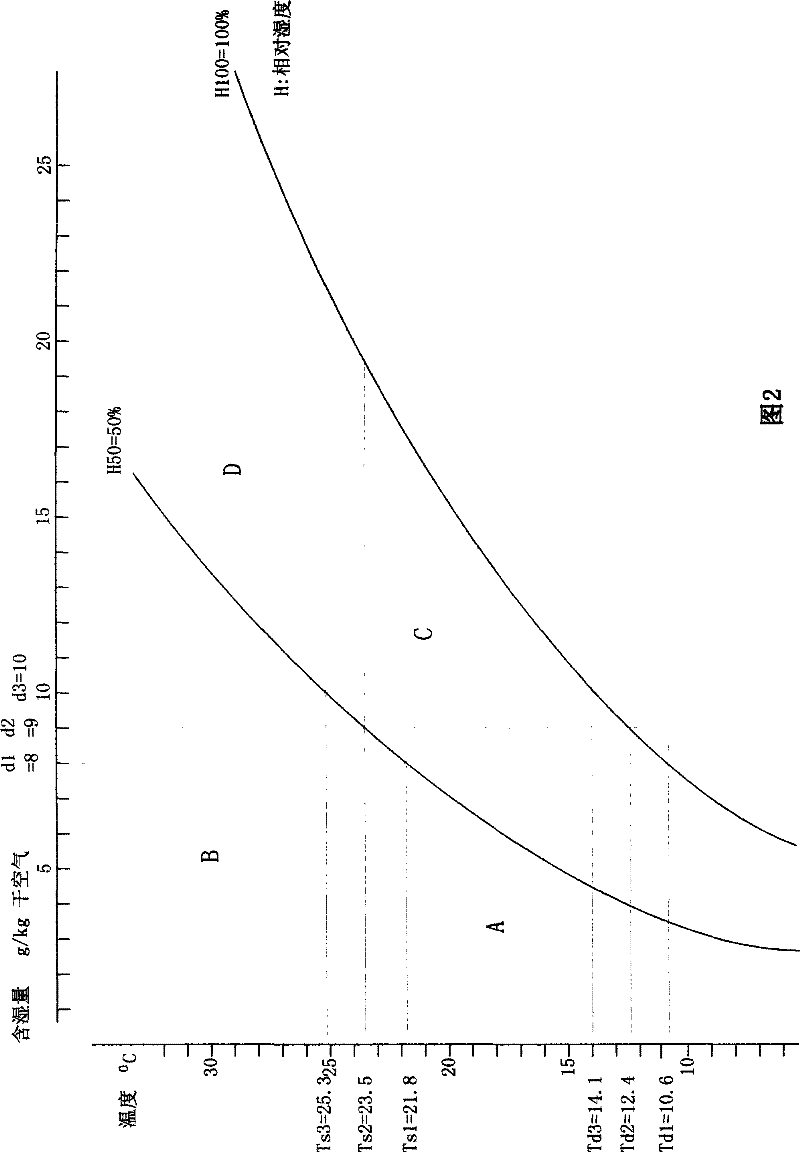

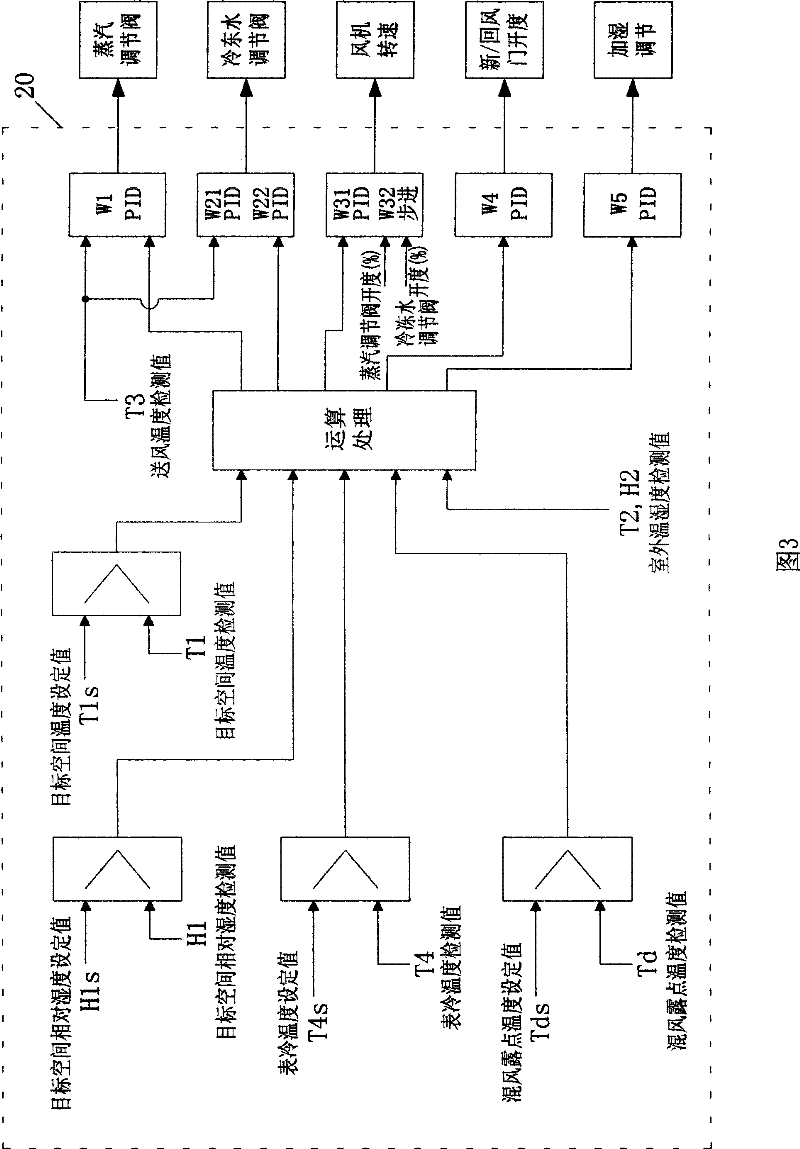

[0050] Figure 4 The first embodiment of the control flow is shown. This embodiment uses as figure 1 The air conditioning unit and controller shown, the control goal to be achieved is that the upper limit of the relative humidity of the target space air is a certain value, namely the relative humidity figure 2 The enthalpy and humidity diagram shows that the dew point temperature Td2 corresponding to the intersection of the relative humidity curve with a relative humidity of 50% and the 23.5°C isotherm is 12.4°C, and the upper limit of the dew point temperature, the set value Tds, is 12.4°C. At the same time, the temperature of 12.4℃ is also used as the temperature setting value T4s after cooling of the monitoring table, and they are stored in the storage unit of the controller, and 23.5℃ is also stored in advance as the target space temperature setting value. unit.

[0051] The control flow of the first embodiment is as Figure 4 As shown, once the main program starts, first in...

Embodiment 2

[0060] Figure 5 The control process of Embodiment 2 of the present invention is shown, and the upper limit of the relative humidity controlled is a certain interval.

[0061] This control process can be applied to air conditioning units in the candy production area of a large candy factory, for example. This area is required to ensure a certain degree of dryness, that is, its upper limit of relative humidity has certain requirements but is not strict, it can be an interval, and its lower limit of relative humidity is not strictly required. Generally speaking, the drier the better. According to the requirements of the production process, the upper limit of the relative humidity control target is 45%-55%; the temperature control target is 23.0-25.0℃. Based on the temperature and humidity target value, the dew point temperature Tds for determining the main flow is set to 12.4° C., which is the same as the setting value of the first embodiment. The dew point temperature setting v...

Embodiment 3

[0073] Some factories or laboratory spaces have strict relative humidity and temperature control requirements, and the relative humidity control target is a certain value. In this case, the relative humidity control target = 50%; the temperature control target = 23.5°C. When the relative humidity of the target space is lower than 50%, humidification control is required; when the relative humidity of the target space is higher than 50%, dehumidification control is required. The temperature control target is also a certain value.

[0074] For the main control flow of this embodiment, see the attachment Image 6 : "Relative humidity is a control process with a certain value." The basic control method is: monitor the dew point temperature of the mixed air in the new return air mixing section to determine which control requirement it meets. Different control strategies are determined according to the mixed air dew point temperature value. If the mixed air dew point temperature value ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com