Screen dot design method of side light type light guide plate of LED light source

A technology of dots on light guide plates and LED light sources, which can be applied in the direction of light guides, light sources, point light sources, etc., and can solve the problem that the dot design of LED side-light backlight modules is difficult to complete in one step

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

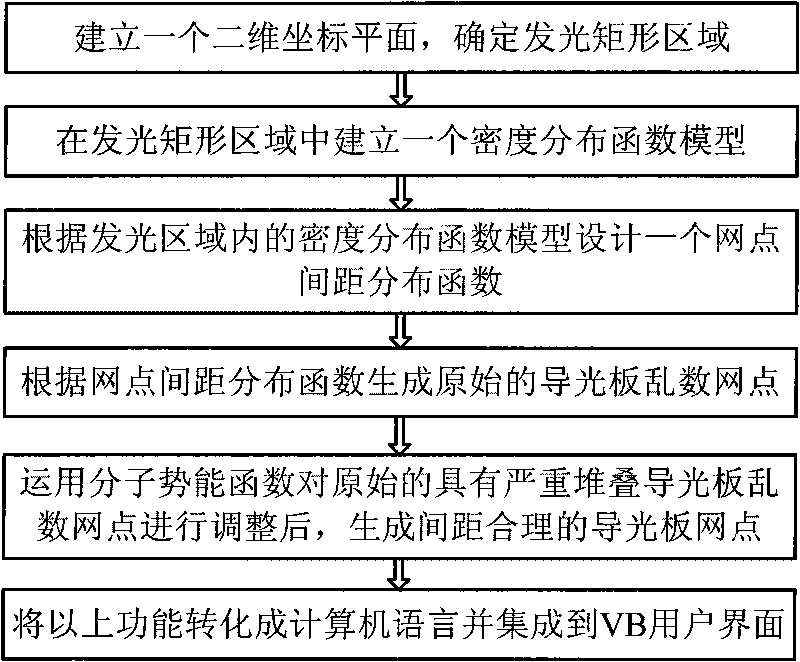

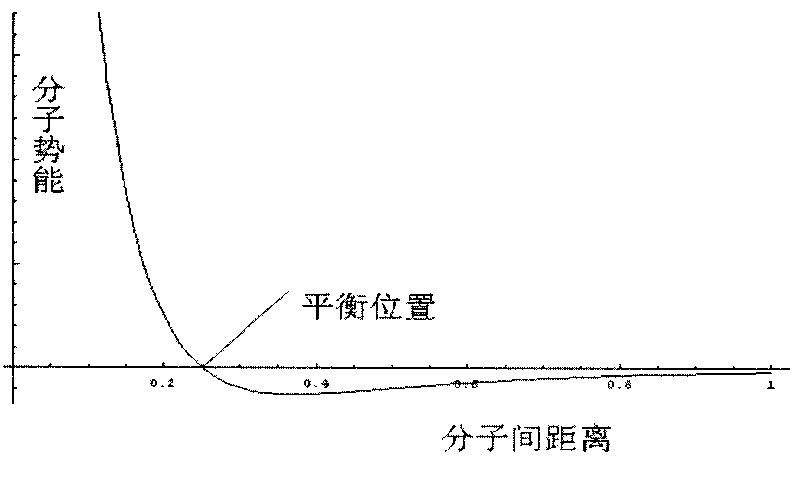

Method used

Image

Examples

Embodiment 1

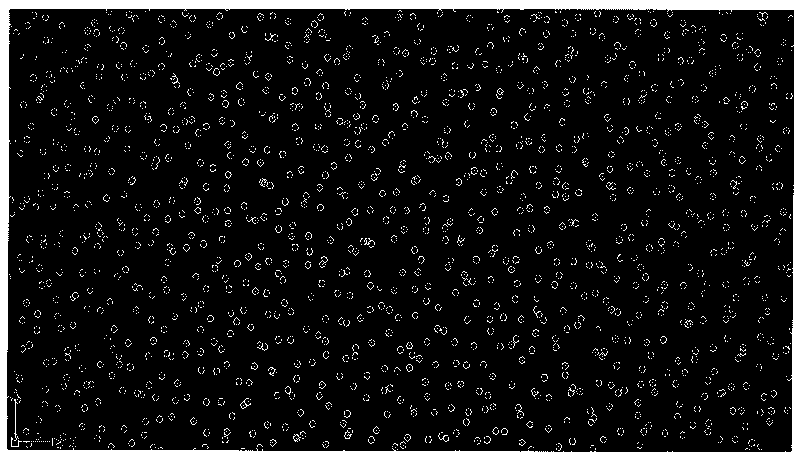

[0051] In order to verify the effect of the application of the present invention on the light guide plate, we will use the user interface of the present invention to generate dots, the length of the light-emitting area is 69.7mm, the width of the light-emitting area is 32.48mm, the relative density value is 0.75, and the number of LEDs is 5. The corresponding LED coordinates are (3.248, 0), (9.744, 0), (16.24, 0), (22.736, 0), (29.232, 0). Enter these parameters Image 6 Click the "OK to generate network" button in the user interface to get the following Figure 7 network points shown. We input the obtained dots into the laser engraving machine and engrave them on the mold core, and then transfer the dots to the light guide plate through plastic molding. It can be seen from the test results that the optical effect of the backlight module can be effectively controlled by using the dots of the light guide plate generated by the present invention, and the uniformity of the back...

Embodiment 2

[0053] Figure 8 It is the dot pattern of the light guide plate of a single LED, the relative density of dots is 0.9, the length of the light-emitting area is 20mm, and the width of the light-emitting area is 20mm. The LED is located in the lower right corner of the entire light-emitting area, from Figure 8 It can be seen that the dot density increases with the increase of the distance between the dot position and the LED.

Embodiment 3

[0055] Figure 9 It is the dot pattern of the light guide plate of two LEDs, the relative density of the dots is 0.9, the length of the light-emitting area is 20mm, and the width of the light-emitting area is 20mm. The coordinate positions of the LEDs are: (5, 0); (15, 0).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com