Automatic stop monitor for laser yarn broken warp/broken weft of spinner

A monitor and textile machine technology, applied in textiles, looms, textiles and papermaking, etc., can solve problems such as difficult alignment of light, achieve low power consumption, simplify initial installation and commissioning and routine maintenance, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

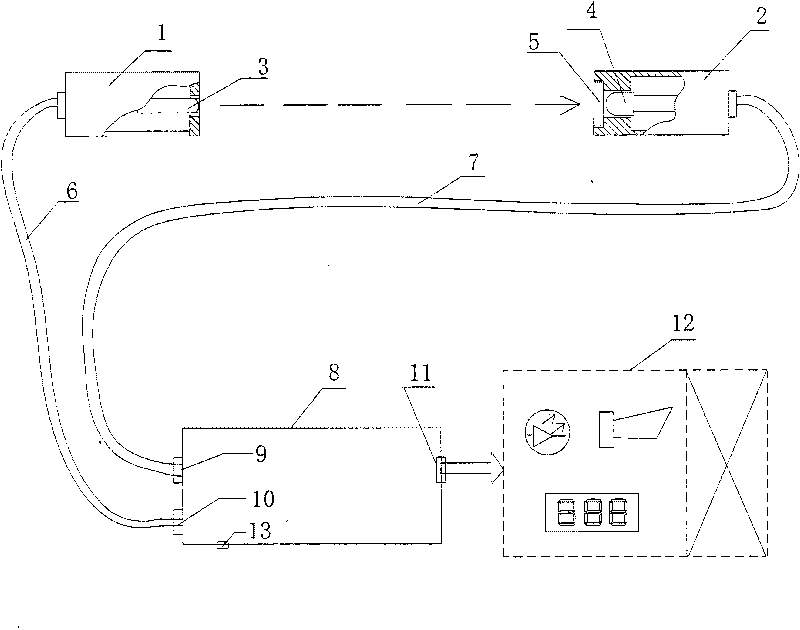

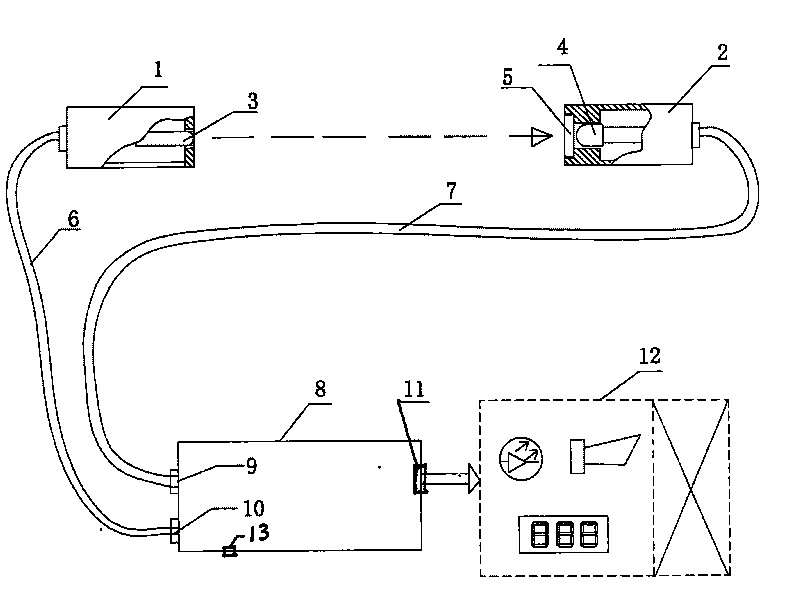

[0019] figure 1 Among them, the transmitting head (1) and the receiving head (2) are aligned on a straight line; the semiconductor laser tube (3) is installed inside the transmitting head (1), and the photosensitive optical device (4) is installed on the receiving head (2) internal;

[0020] The transmitting head cable (6) is connected to the connection port (10) of the monitor assembly (8), and the receiving head cable (7) is connected to the connection port (9) of the monitor assembly (8);

[0021] The control output port (11) of the monitor assembly (8) is connected to the external sound and light alarm display unit and the self-stop electrical control element (12);

[0022] Color filter lens (5) is installed at the front end of receiving head (2) photosensitive device,

[0023] The external working power is connected to the power port (13) of the monitor assembly (8).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com